Preparation method and application of manganese copper composite oxide catalyst

A manganese-copper composite and oxide technology, which is applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve complex control, poor repeatability, and complex crystal phases of materials and other issues to achieve the effect of good reusability and good commercial application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

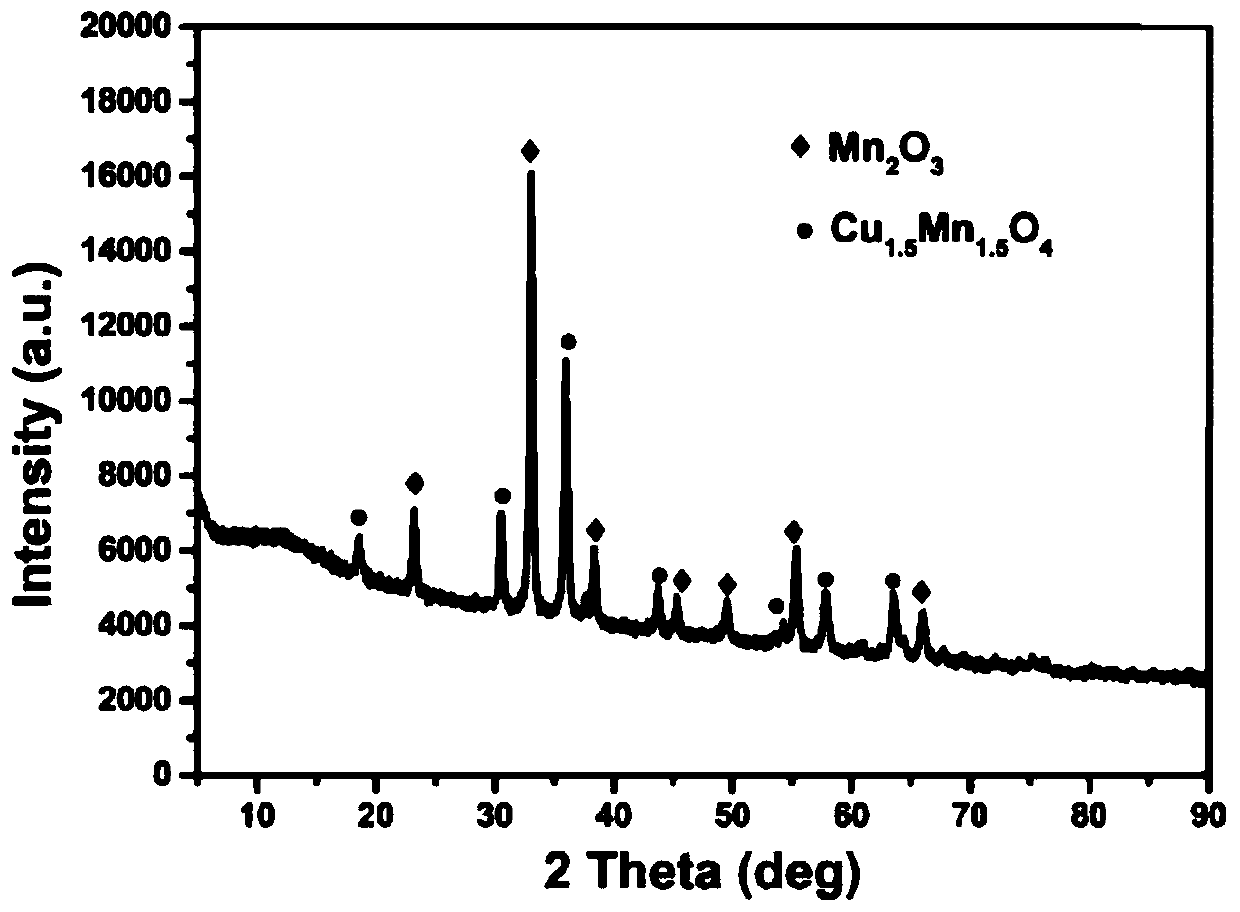

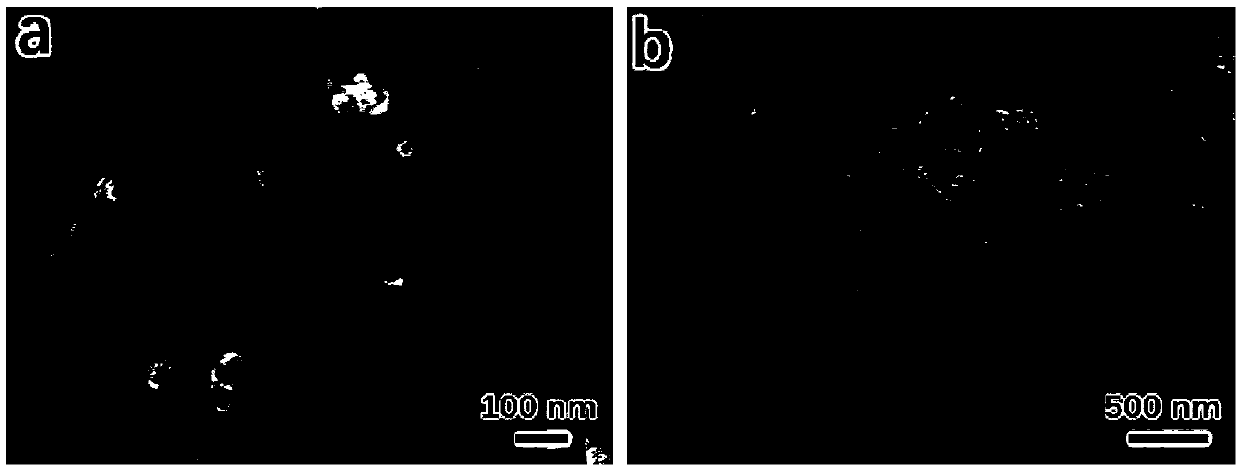

[0027] Manganese acetate (Mn(CH 3 COO) 2 ) is manganese source, trimesic acid (H 3 BTC) is an organic ligand, copper acetylacetonate is a copper source, deionized water and ethanol are a mixed solvent, and the molar composition of each raw material is Mn(CH 3 COO) 2 :H 3 BTC: Copper acetylacetonate: H 2 O: ethanol is 1:3:0.4:560:520. Various raw materials were stirred and reacted at 25°C for 15 h, and the obtained solid was filtered, washed and dried to obtain a light green powder product, which was a copper ion-modified manganese metal organic framework (Cu 2+ / Mn-BTC). Will Cu 2+ / Mn-BTC powder was calcined in a muffle furnace at 500° C. for 3 h to obtain a manganese-copper composite oxide catalyst (the catalyst number is A). XRD characterization results such as figure 1 , indicating that the main chemical components of the catalyst are copper-manganese spinel (standard PDF card number #01-070-0260) and manganese trioxide (standard PDF card number #00-041-1442). FE...

Embodiment 2

[0029] Manganese acetate (Mn(CH 3 COO) 2 ) is manganese source, trimesic acid (H 3 BTC) is an organic ligand, copper acetylacetonate is a copper source, polyvinylpyrrolidone (PVP) is a surfactant, deionized water and ethanol are a mixed solvent, and the molar composition of each raw material is Mn(CH 3 COO) 2 :H 3 BTC: copper acetylacetonate: PVP: H 2 O: ethanol is 1:3:0.04:0.005:560:520. Various raw materials were stirred and reacted at 25°C for 15 hours, and the obtained solid was filtered, washed and dried to obtain a light green powder product, which was a copper ion-modified manganese metal organic framework (Cu 2+ / Mn-BTC). Will Cu2+ / Mn-BTC powder was calcined in a muffle furnace at 500°C for 3h to obtain a manganese-copper composite oxide catalyst (the catalyst number is B). FESEM characterization results such as figure 2 b, shows that the obtained catalyst B is mainly composed of large spherical particles self-assembled by nano-scale particles (average partic...

Embodiment 3

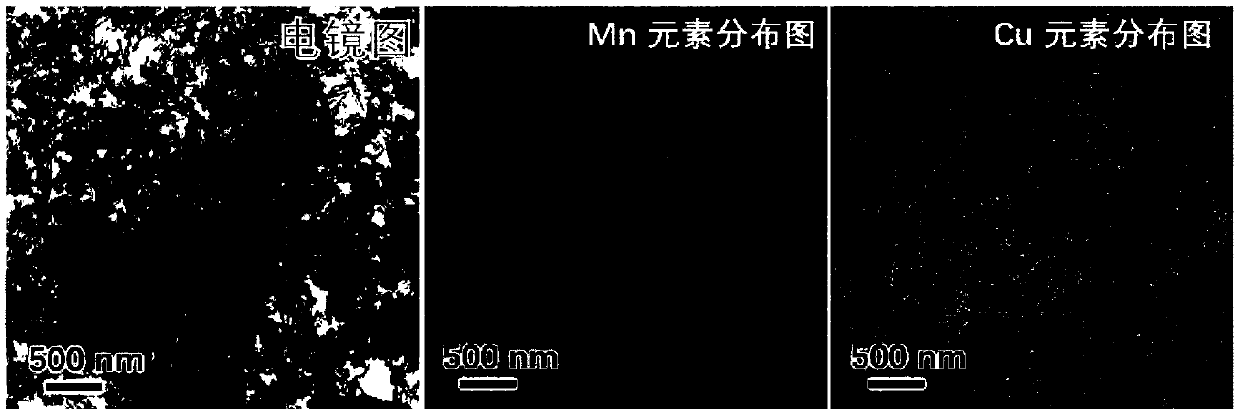

[0031] Manganese acetate (Mn(CH 3 COO) 2 ) is manganese source, trimesic acid (H 3 BTC) is an organic ligand, copper acetylacetonate is a copper source, cetyltrimethylammonium bromide (CTAB) is a surfactant, deionized water and ethanol are a mixed solvent, and the molar composition of each raw material is Mn(CH 3 COO) 2 :H 3 BTC: copper acetylacetonate: CTAB: H 2 O: ethanol is 1:3:0.5:1:560:520. Various raw materials were stirred and reacted at 25°C for 20 h, and the resulting solid was filtered, washed and dried to obtain a light green powder product, which was a copper ion-modified manganese metal organic framework (Cu 2+ / Mn-BTC). Will Cu 2+ / Mn-BTC powder was calcined in a muffle furnace at 500° C. for 3 h to obtain a manganese-copper composite oxide catalyst (the catalyst number is C). EDX element surface scan results are as follows image 3 As shown, it shows that in the obtained catalyst C, the copper element and the manganese element are uniformly distributed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com