Automatic glass panel machining device and preparing method applying automatic glass panel machining device

A technology for processing devices and glass panels, which is applied in glass manufacturing equipment, glass cutting devices, lighting and heating equipment, etc., can solve the problems of increasing the labor burden of operators and unfavorable automation, etc., to achieve a high degree of automation, improve efficiency, and reduce times product effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

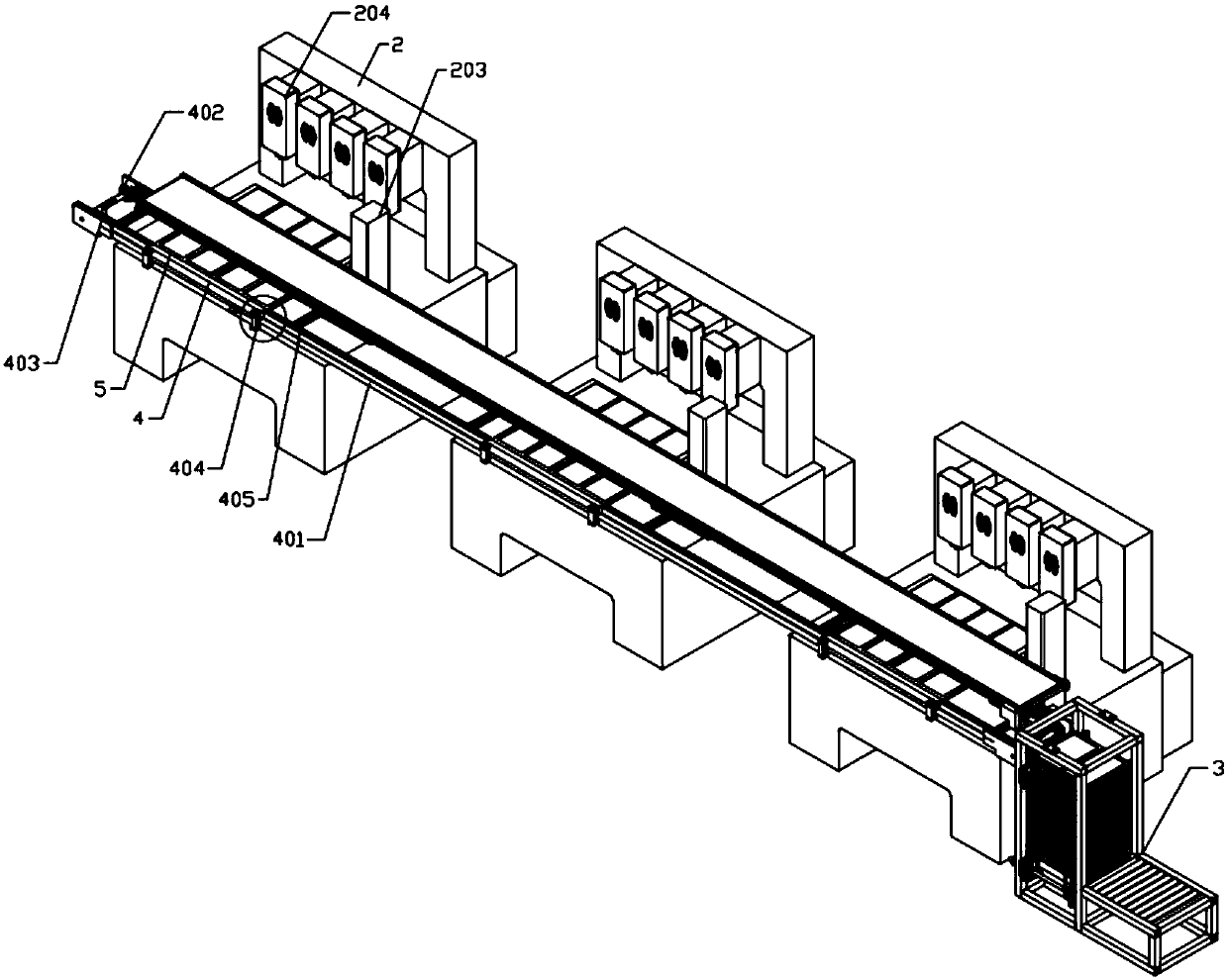

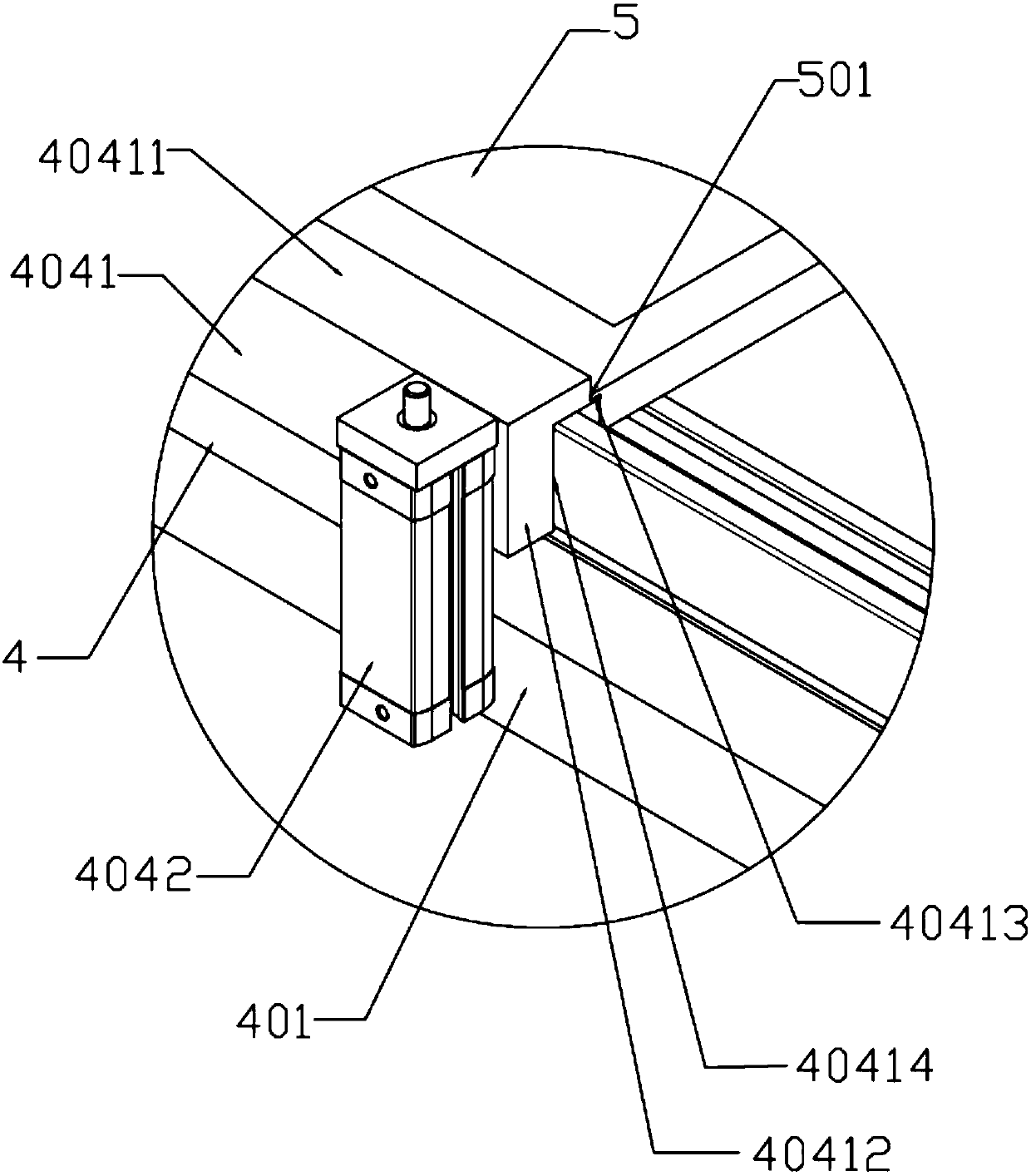

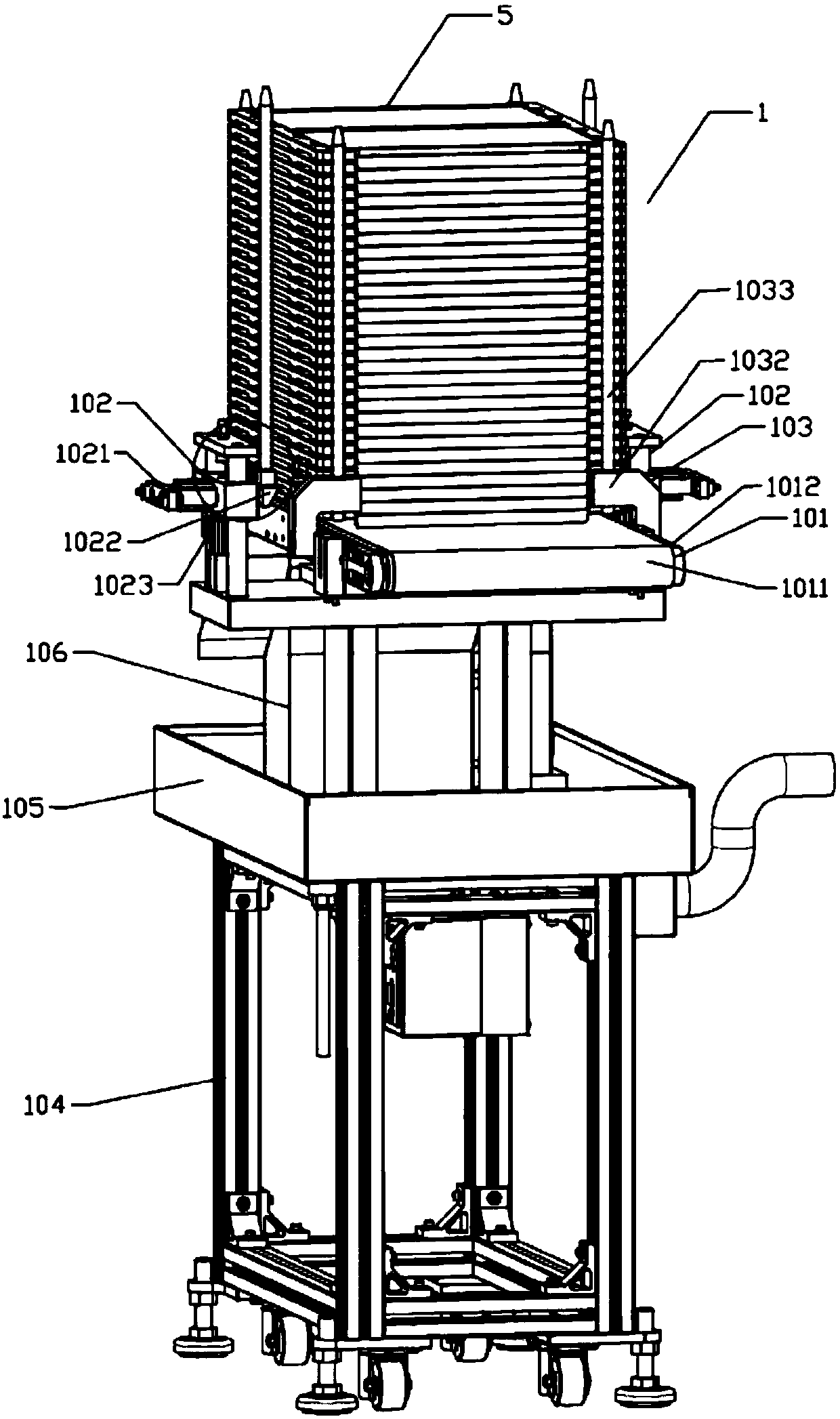

[0032] Combine below Figure 1-Figure 6 The present invention is described in further detail.

[0033] like figure 1 As shown, an automatic glass panel processing device is provided, including a processing machine tool 2 , an automatic feeding device 1 , a closing device 3 and a conveying combination device 4 . Wherein, processing machine tool 2 comprises workbench 201, cutter beam 202, cutter 204 and clamping device 203, and cutter beam 202 is arranged on the workbench 201 side, and cutter 204 is arranged on cutter beam 202, and clamping device 203 can hold material frame 5 The materials in the workbench are picked up and placed on the workbench 201 , and the cutter 204 can process the materials placed on the workbench 201 . Among them, such as Figure 5 As shown, the clamping device 203 includes a support base 2031 and a manipulator 2032 disposed on the support base 2031 . The manipulator 2032 is perpendicular to the support base 2031 , and the support base 2031 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com