A fireproof composition for preparing fireproof glass and its preparation method

A technology for fire-resistant glass and its composition, which is applied in the field of fire-resistant composition for fire-proof glass and its preparation, fire-proof composition and its preparation, and can solve the problems of low adhesion of fire-proof liquid, affecting fire-proof performance, and poor anti-aging performance. To achieve the effect of improving adhesion, improving efficiency and good fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

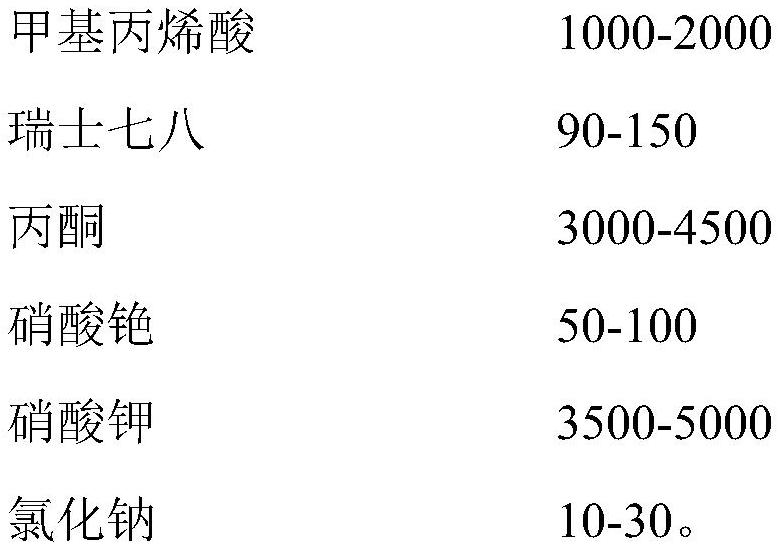

[0040] 1. Prepare raw materials according to the following weight ratio (g)

[0041]

[0042]

[0043] 2. Pour the raw materials potassium nitrate, cesium nitrate, Swiss seven-eight, methacrylic acid, acetone, and table salt into a plastic container filled with water in sequence, and use an electric stirrer to stir for mixing. The stirring rate is 120rpm (usually 60-120rpm); stirring time is 1.5h;

[0044] 3. Stir and mix the mixed solution for 1.5 hours, and place it at a temperature of 25°C to allow it to fully blend with each other, and leave it to react for 48 hours to obtain the fireproof composition of the present invention.

Embodiment 2

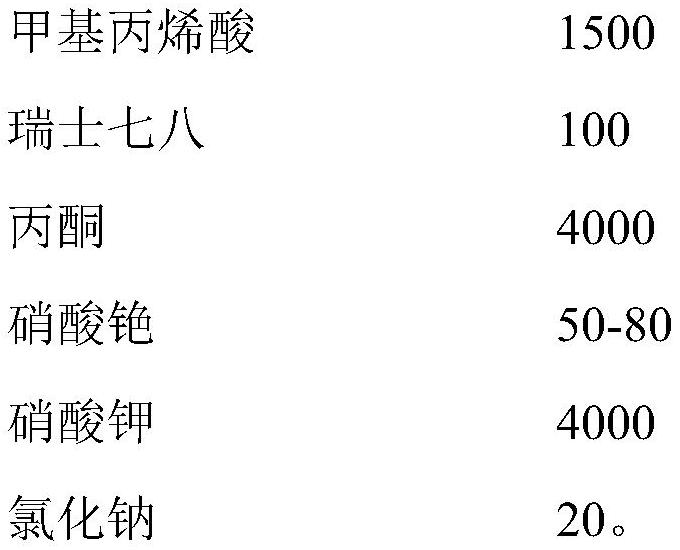

[0046] 1. Prepare raw materials according to the following weight ratio (g)

[0047]

[0048] 2. Pour the raw materials potassium nitrate, cesium nitrate, Swiss seven-eight, methacrylic acid, acetone, and salt into a plastic container filled with water in sequence, and use an electric stirrer to stir for mixing treatment, wherein the stirring rate is 100rpm (usually 60-120rpm); Stirring time is 2h;

[0049] 3. Stir and mix the mixed solution for 2 hours, and place it under the temperature condition of 25° C. to fully fuse with each other to generate oxidation and reduction reactions. After standing for 50 hours, the fireproof composition of the present invention is obtained.

Embodiment 3

[0051] 1. Prepare raw materials according to the following weight ratio (g)

[0052]

[0053]

[0054] 2. Pour the raw materials potassium nitrate, cesium nitrate, Swiss seven-eight, methacrylic acid, acetone, and table salt into a plastic container filled with water in sequence, and use an electric stirrer to stir for mixing. The stirring rate is 60rpm (usually 60-120rpm); Stirring time is 2h;

[0055] 3. Stir and mix the mixed solution for 2 hours, and place it under the temperature condition of 25° C. to fully fuse with each other to generate oxidation and reduction reactions. After standing for 60 hours, the fireproof composition of the present invention is obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface stress | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| service temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com