A large-tonnage graded continuous force-measuring force-adjusting support and cluster control system

A technology of cluster control and large tonnage, which is applied in the field of urban bridges and building structures, railways, and highways. It can solve the problems of monitoring and evaluating the health status of unfavorable bridge structures, interrupting the current traffic, and lack of force measurement functions, etc., to achieve force measurement. And the effect of simple and reliable force adjustment method, convenient installation and replacement, and strong adaptability to working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

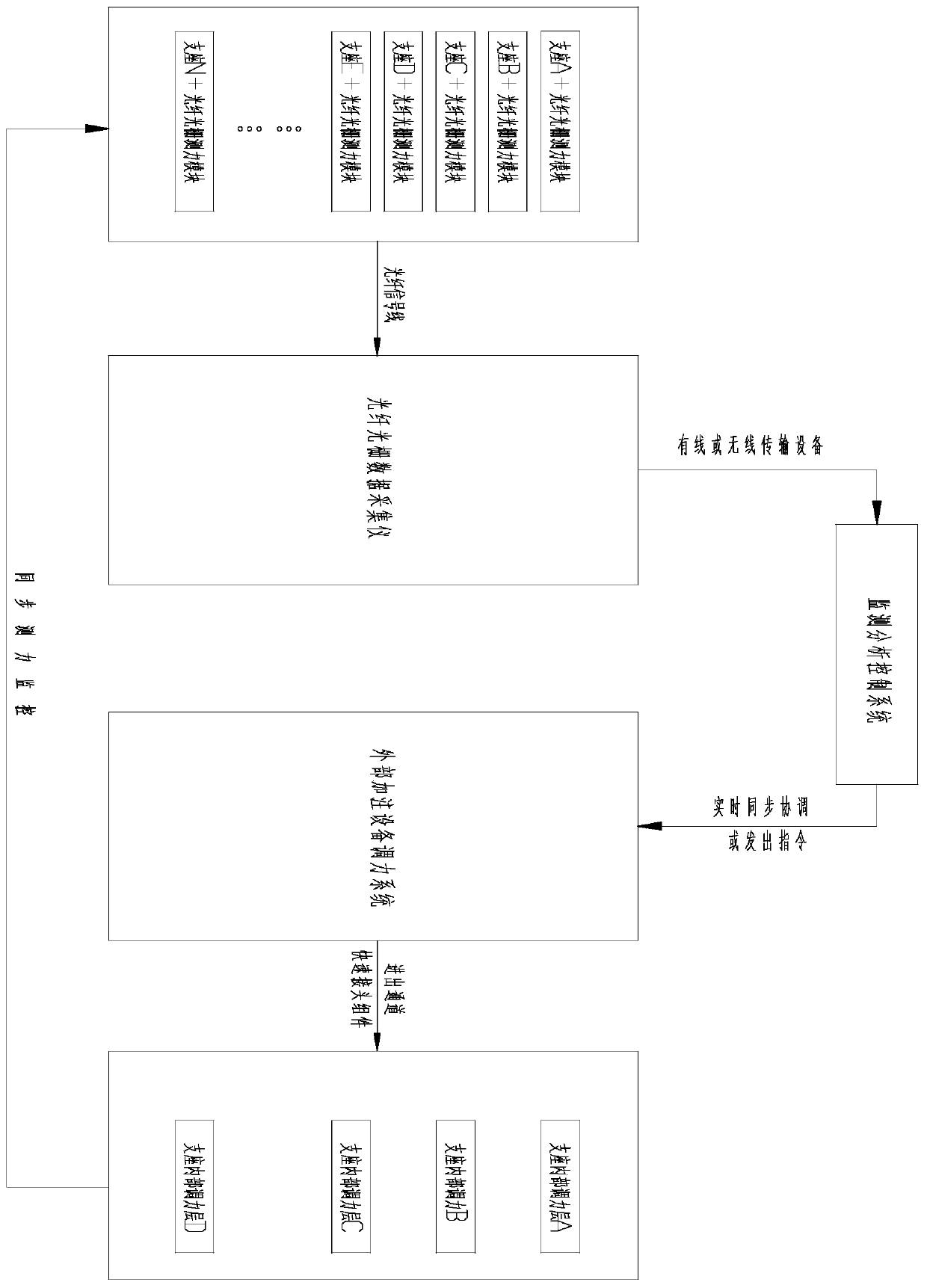

[0037] refer to figure 1 , the present invention is a large-tonnage graded continuous force-measuring force-adjusting support and cluster control system, including multiple support body systems, force-measuring sensor acquisition systems, force-adjusting systems, and monitoring, analysis and control systems.

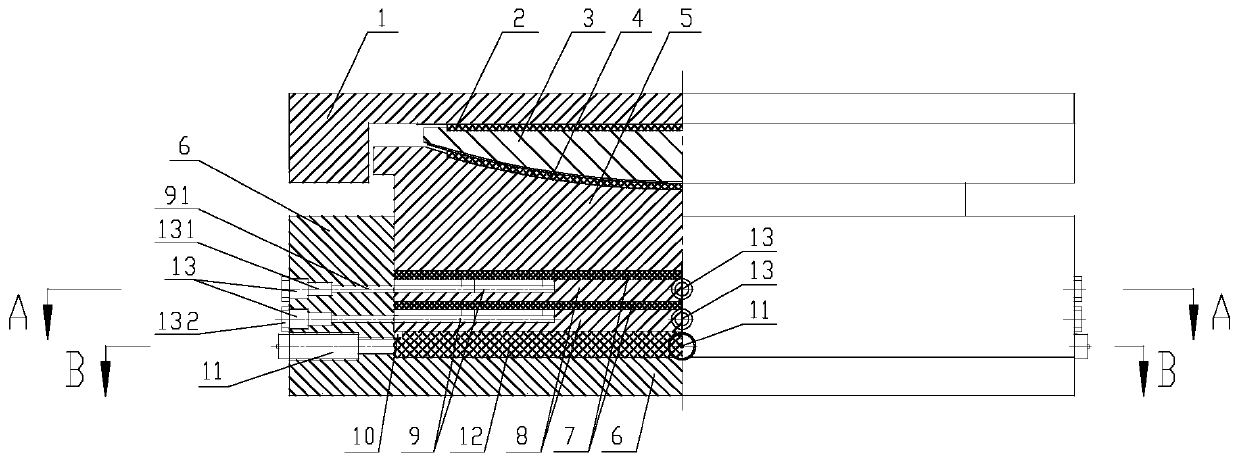

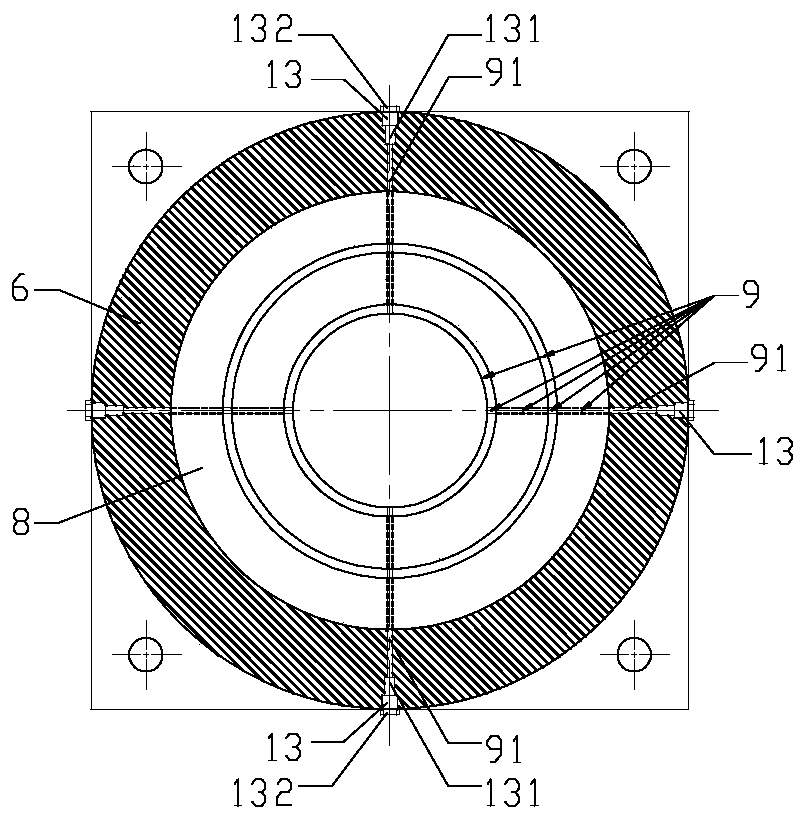

[0038] Such as Figure 2 to Figure 8 As shown, the support body system includes a support top plate 1, a flat wear plate 2, a spherical crown steel lining plate 3, a spherical wear plate 4, a concave spherical steel liner plate 5, and a support bottom plate 6. There is a spherical crown steel lining plate 3 under the support top plate 1, and the top surface of the spherical crown steel lining plate 3 is fastened with a flat wear-resistant plate 2, and its sliding surface cooperates with the mirror stainless steel plate welded to the bottom surface of the support top plate 1 to form a plane sliding friction vice. The outer periphery of the base plate 6 of the support ha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com