Method for observing fracture permeability of variable-pressure adjustable rock mass

A rock mass fissure and permeability technology, applied in the direction of earthwork drilling and production, wellbore/well components, etc., can solve the problems of unstable working process, troublesome operation process, and intertwined pipelines, etc., and achieves a wide range of pressure regulation and a simple method , to avoid the effect of winding problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and technical solutions.

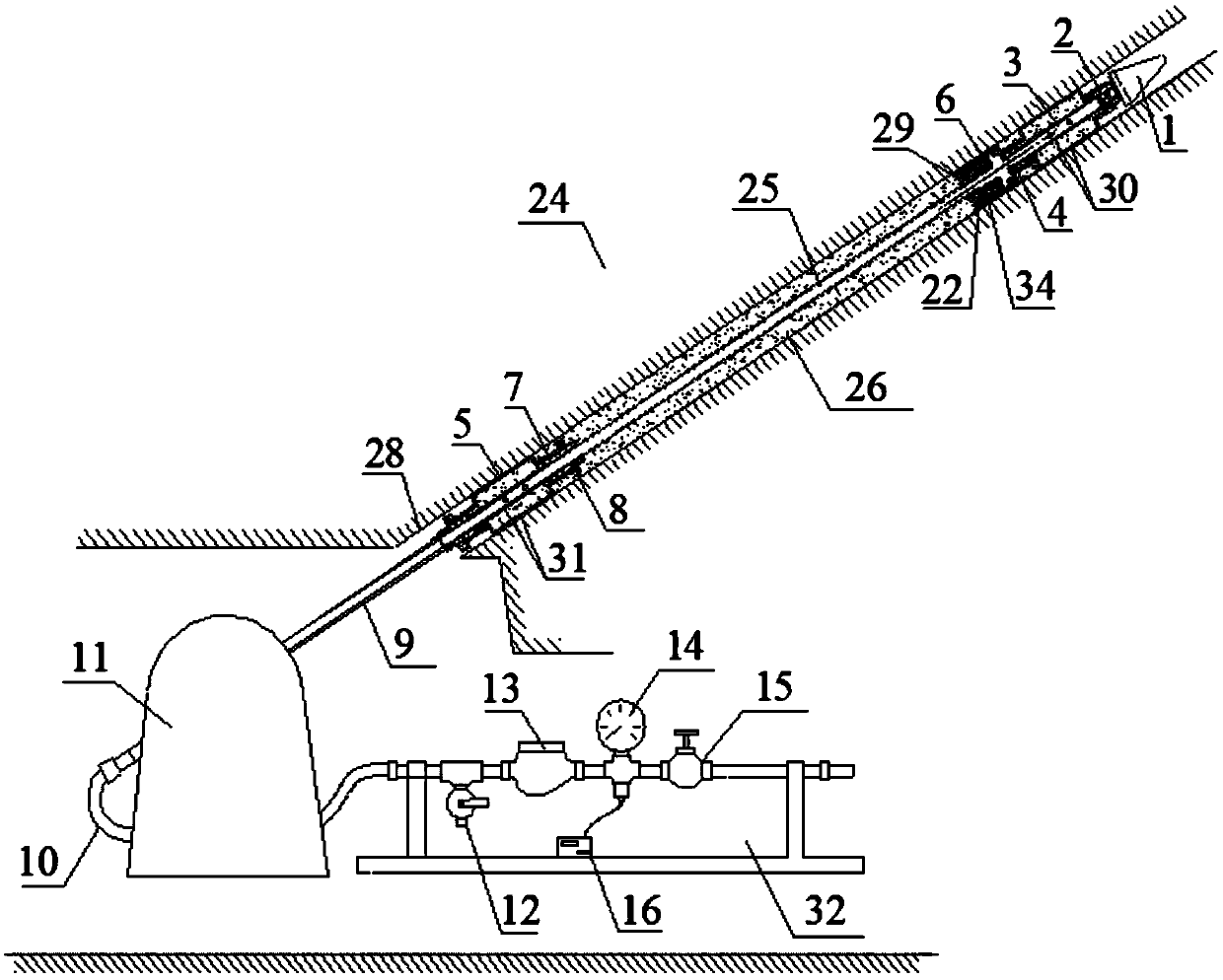

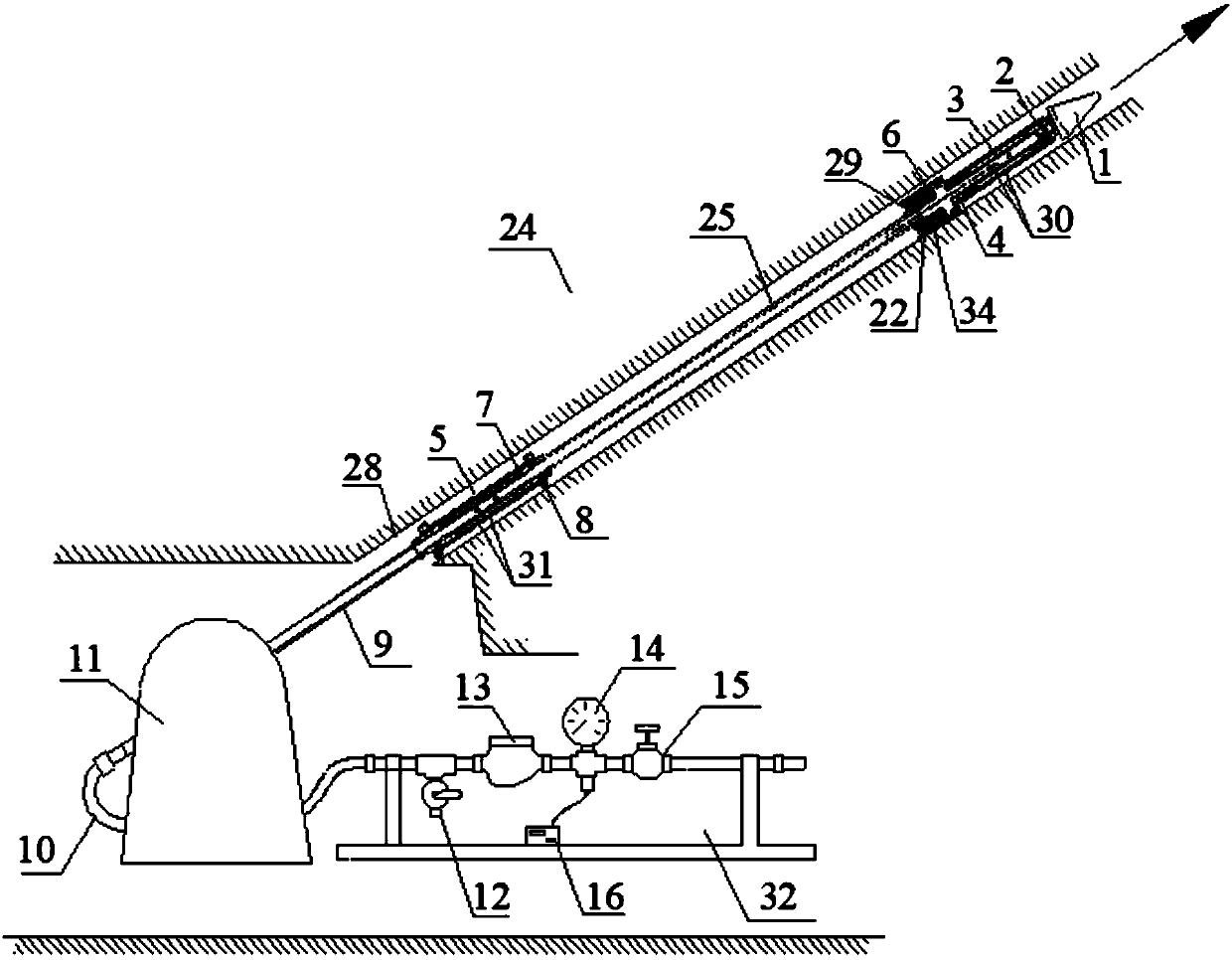

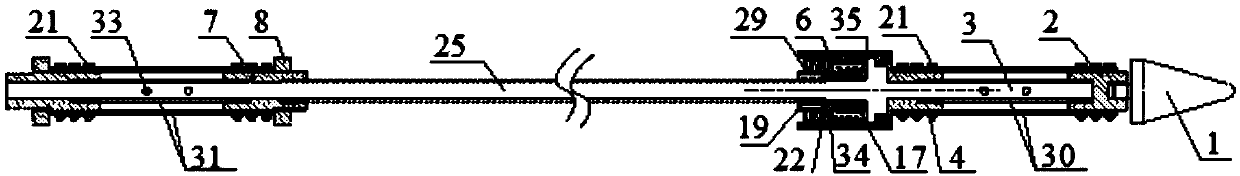

[0055] A pressure-variable and adjustable rock mass fracture permeability testing device, including a plugging device, a converter 6, a connecting pipe 25, a drilling rig 11, a drill pipe 9 and a control console 32; the plugging device further includes a front plug Blocker 30 and tail blocker 31;

[0056] The converter 6 is threadedly connected to the tail of the front occluder 30, and its interior includes an inner ring 34, a spring 22 and a cross wire sleeve 29. By adjusting the position of the cross wire sleeve 29, the compression degree of the spring 22 is changed, thereby controlling Opening pressure of the inner ring 34; after the front occluder 30 and the rear occluder 31 are inflated, they form a water injection cavity 26 with the borehole 28, and the external high-pressure water enters the water in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com