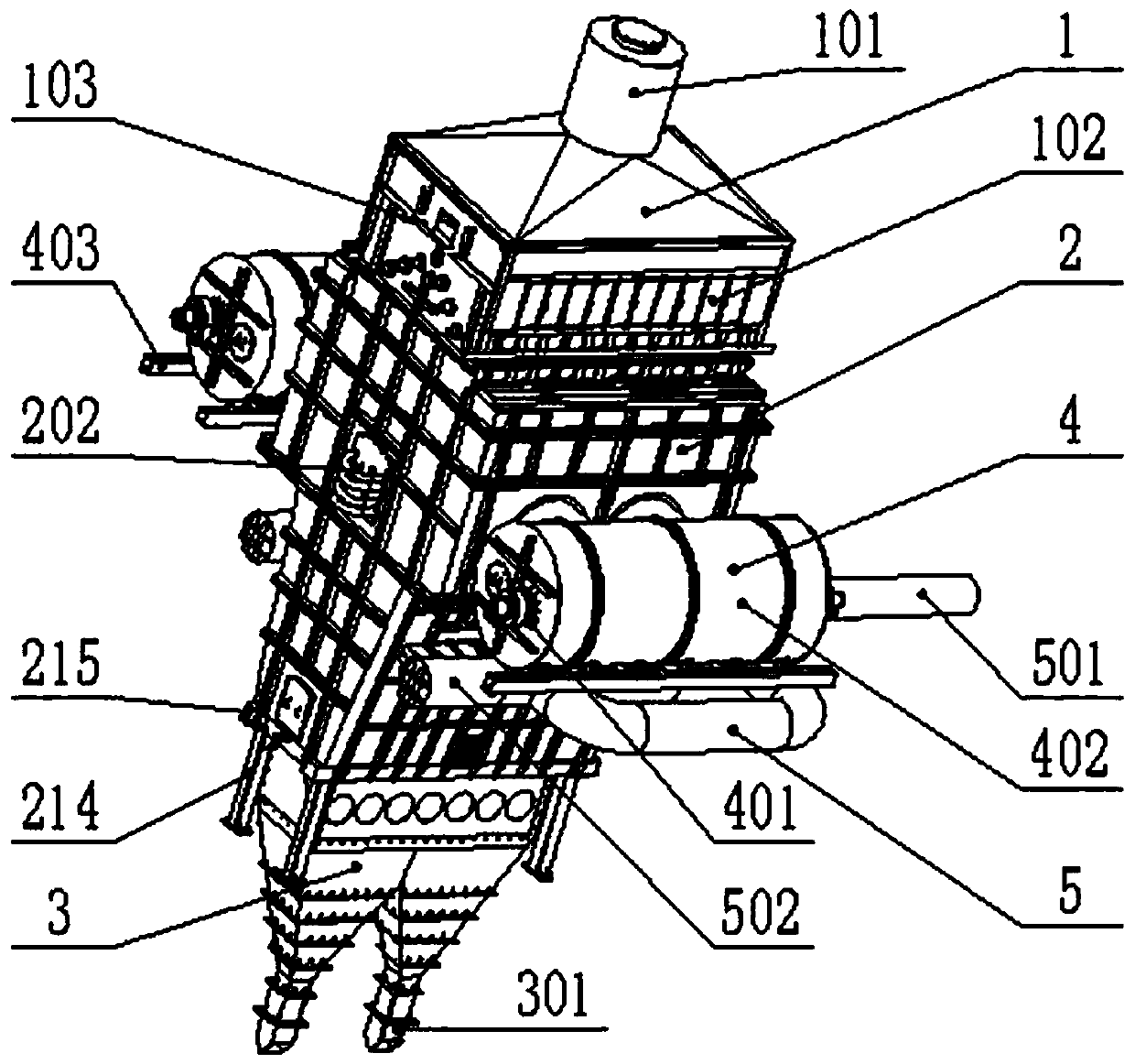

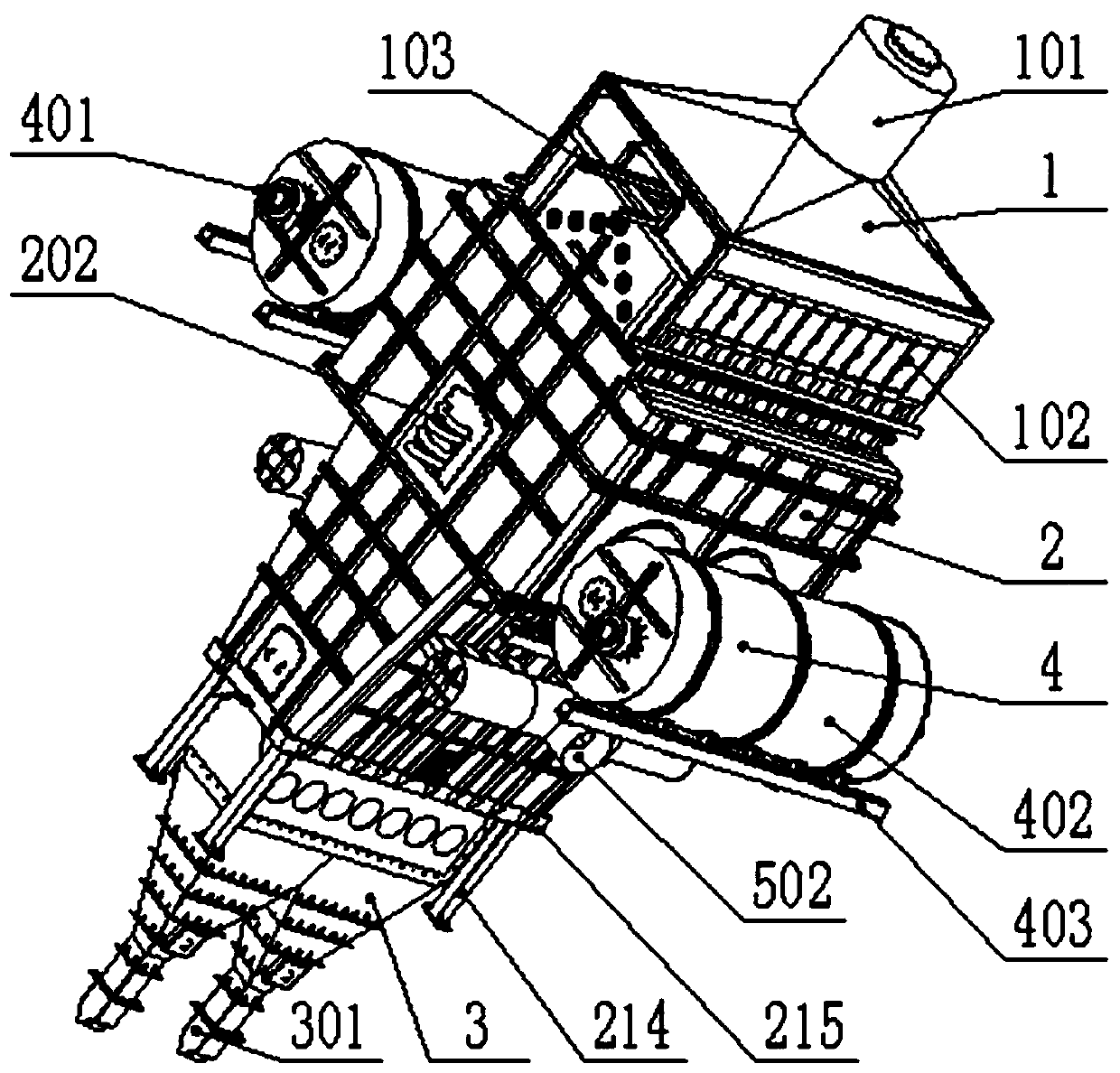

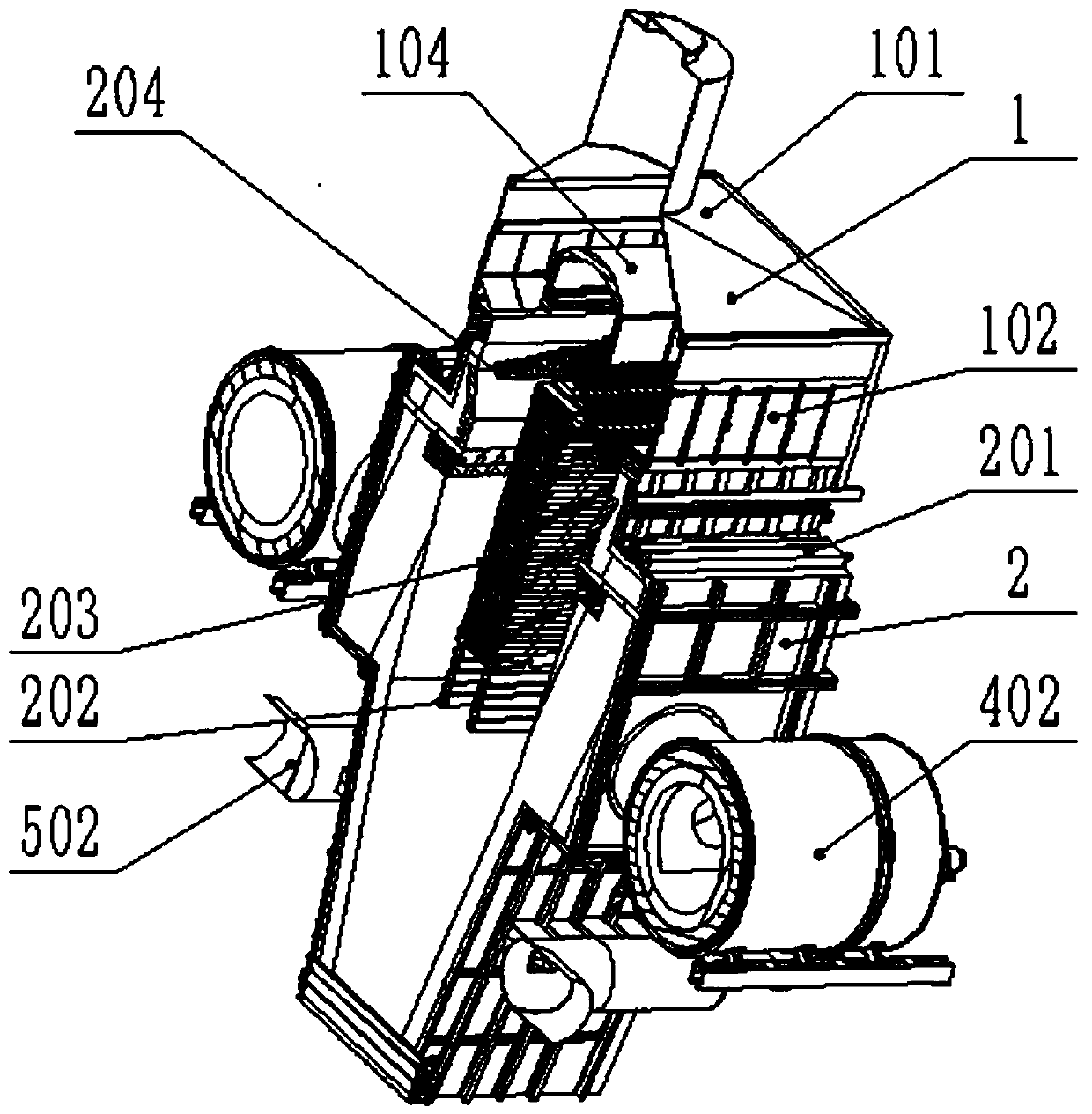

Rectangular shaft furnace for roasting ferrochromium pellets and roasting method thereof

A ferrochrome alloy and roasting technology, which is applied in the direction of furnaces, furnace materials, vertical furnaces, etc., can solve the problems of large investment, raw firing, and less practical application, and achieve the effects of uniform pellet roasting, high roasting intensity, and good smelting indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0061] Embodiment 2, the rectangular shaft furnace and its roasting method for ferrochrome alloy pellet roasting of the present embodiment are basically the same as that of Example 1, the difference is that the roasting parameters are different, and the specific methods are as follows:

[0062] 1) Feeding, the ferrochrome green pellets are transported to the top of the drying bed 204 via a distributor, and the ferrochrome green pellets have a particle size of 10-25mm;

[0063] 2) drying, the ferrochrome green pellets transported to the drying bed 204 enters the pre-tropical zone 209 after being dried at 350° C. on the drying bed 204, and the drying time is 35 minutes;

[0064] 3) Preheating, the ferrochrome green pellets that enter the preheating zone 209 are preheated at 500°C for 20 minutes in the preheating zone 209, and the ferrochrome green pellets enter the roasting zone 208 after preheating;

[0065] 4) Roasting, the ferrochrome green pellets entering the roasting zone ...

Embodiment 3

[0070] Embodiment 3, the present embodiment ferrochromium alloy pellet roasting rectangular shaft furnace and its roasting method are basically the same as Example 1, the difference is that the roasting parameters are different, the specific method is as follows:

[0071] 1) Feeding, the ferrochrome green pellets are transported to the top of the drying bed 204 via a distributor, and the ferrochrome green pellets have a particle size of 10-25mm;

[0072] 2) drying, the ferrochrome green pellets transported to the drying bed 204 enters the pre-tropical zone 209 after being dried at 250° C. on the drying bed 204, and the drying time is 28 minutes;

[0073] 3) preheating, the ferrochrome green pellets that enter the preheating zone 209 are preheated at 450 ° C for 14 minutes in the preheating zone 209, and the ferrochrome green pellets enter the roasting zone 208 after preheating;

[0074] 4) roasting, the ferrochrome green pellets entering the roasting zone 208 are roasted at 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com