Linear laser phase-shift interference triangular micro-displacement measuring device and method

A phase-shifting interference and measurement device technology, applied in the field of ultra-precision measurement, can solve problems such as low work efficiency, complex structure, and limited application range, and achieve the effects of improving measurement efficiency, signal-to-noise ratio, and lateral resolution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

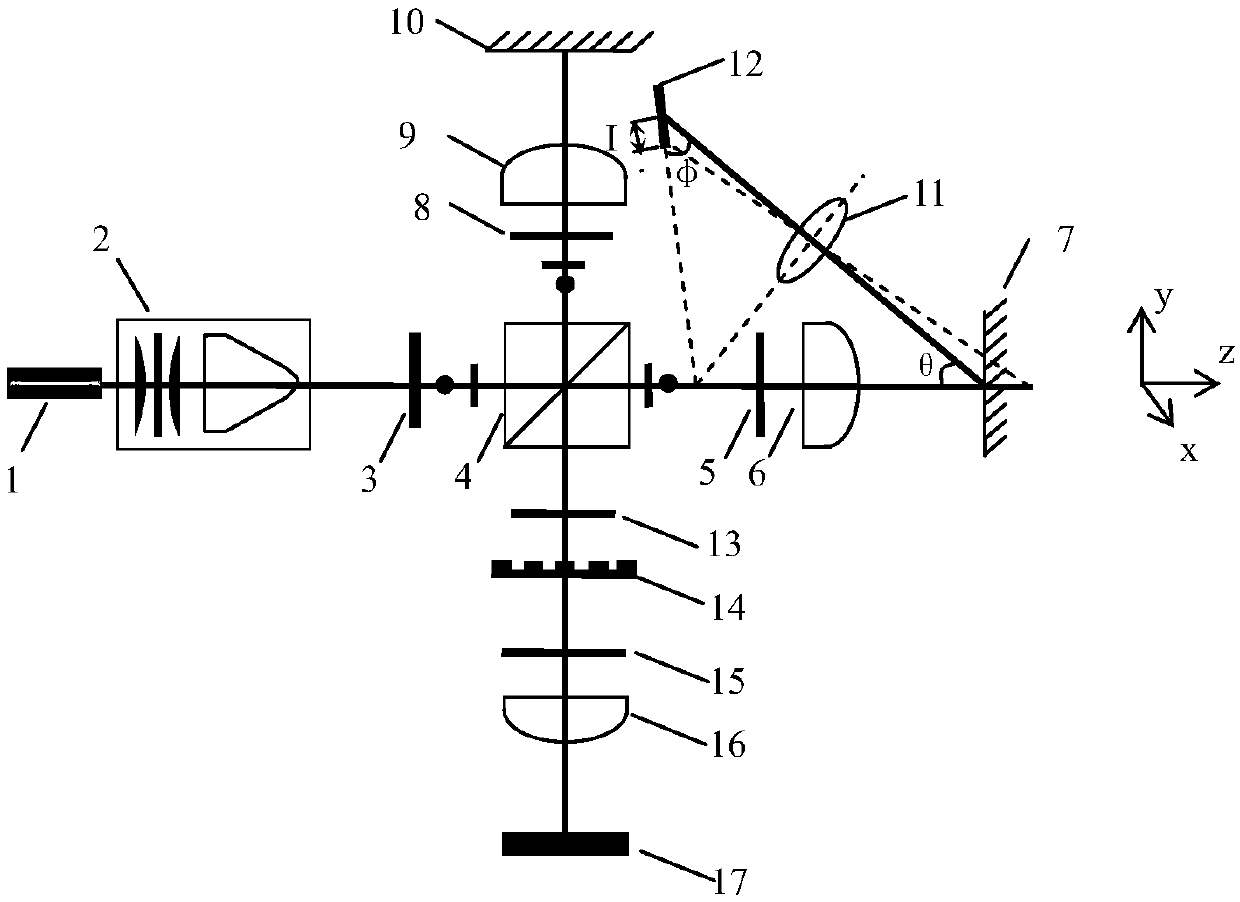

[0047] as attached figure 1 As shown, the example of the present invention provides a laser interference triangulation micro-displacement measurement device and method.

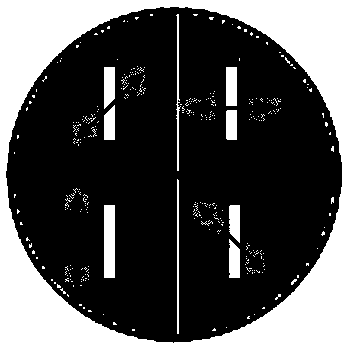

[0048] The device and method for measuring displacement by phase-shifting interference triangulation of the present invention include a laser (1), a shaping beam expander (2), a 1 / 2 wave plate (3), a polarizing beam splitter (4), and a first 1 / 4 wave plate (5), the first cylindrical mirror (6), the measured object surface (7), the second 1 / 4 wave plate (8), the second cylindrical mirror (9), the reference surface (10), the imaging lens ( 11), the first CCD (12), the third 1 / 4 wave plate (13), the two-dimensional Ronchi grating (14), the four-quadrant analyzer group (15), the third cylindrical mirror (16), the second CCD (17).

[0049] Wherein the laser (1), the shaping beam expander (2), and the 1 / 2 wave plate (3) form the polarized line light source part.

[0050] Among them, the line laser phase-shiftin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com