Centrifugal impeller vibration damping test system and method

A centrifugal impeller and vibration damping technology, which is applied in the field of compressors, can solve the problems that it is difficult to directly measure the vibration damping data of the rotating impeller, there is no impeller test system and method, and the aerodynamic damping is not simple and feasible, etc. Simple, simultaneous measurement, easy installation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with embodiment technical solution of the present invention is made more specific description:

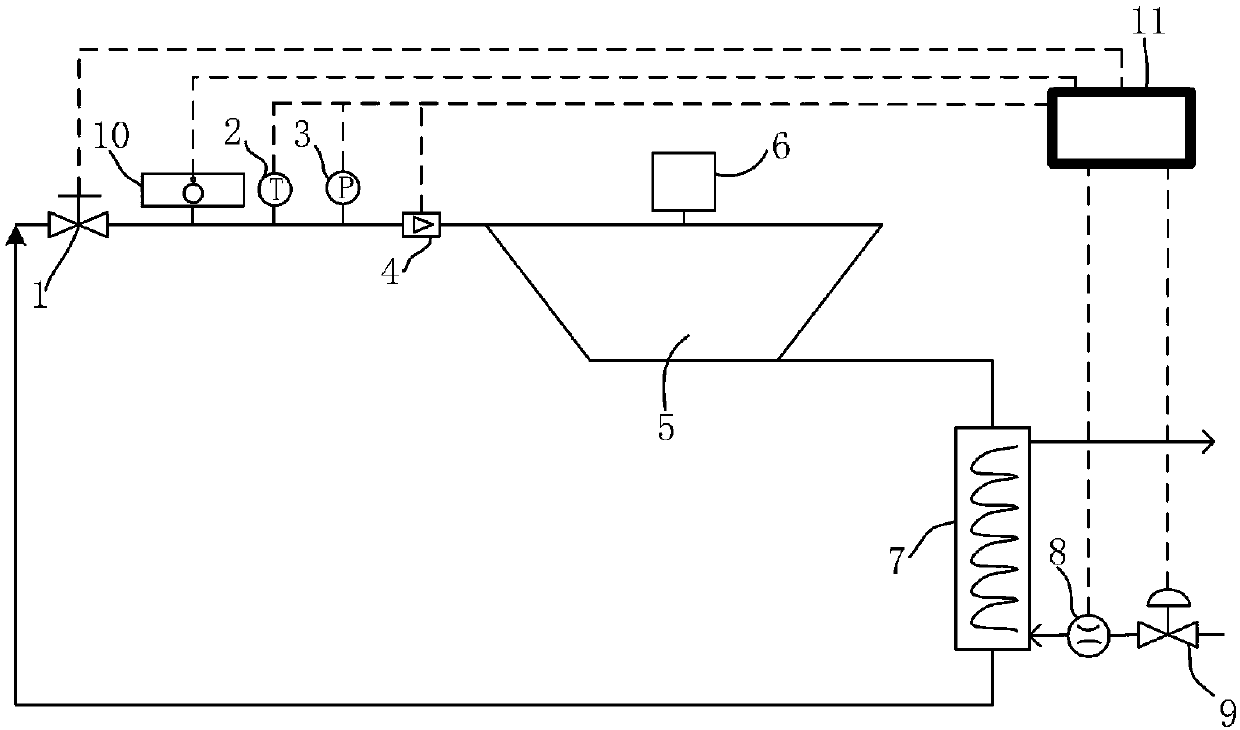

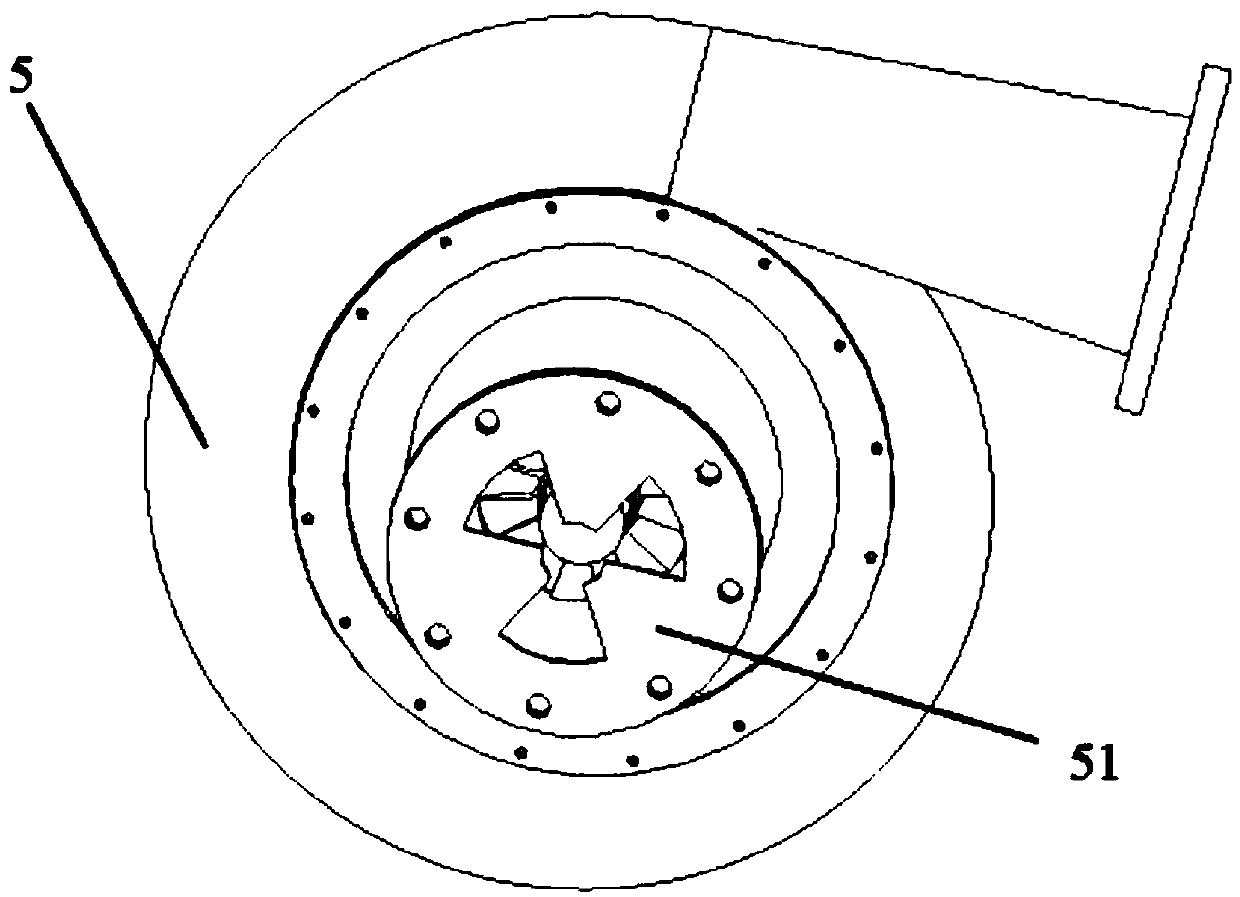

[0033] Such as figure 1 , 4 , 5: the centrifugal impeller vibration damping test system of the present invention includes a closed loop system, a wireless receiving gateway 10 and a terminal control unit 11:

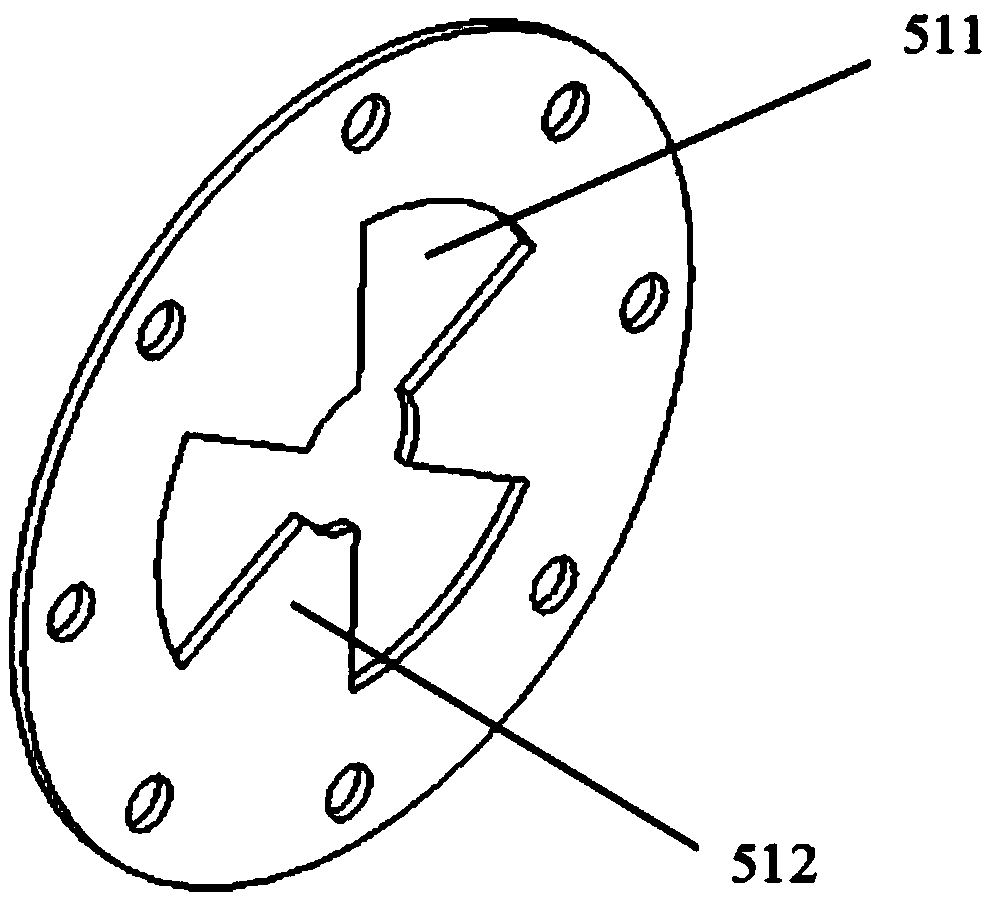

[0034] The closed loop system includes a centrifugal compressor 5 to be tested and a cooler 7, a throttle valve 1, a temperature sensor 2, a pressure sensor 3, and a cooler 7 arranged sequentially from the outlet of the centrifugal compressor 5 to the inlet of the centrifugal compressor 5. A flow meter 4; the cold source inlet end of the cooler 7 is provided with a regulating valve 9 and a second flow meter 8 arranged in sequence along the flow direction of the cold source.

[0035] The surface of the centrifugal impeller 52 of the centrifugal compressor where it is located is equipped with a strain sensor 521 for measuring blade strain. The wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com