Flexible transparent voltage-controlled film capacitor and preparation method thereof

A film capacitor and transparent technology, applied in the direction of variable voltage capacitors, etc., can solve the problems of high microwave loss of devices, failure to realize full transparency and flexibility of devices, etc., and achieve low dielectric loss, wide application, and high tuning rate high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

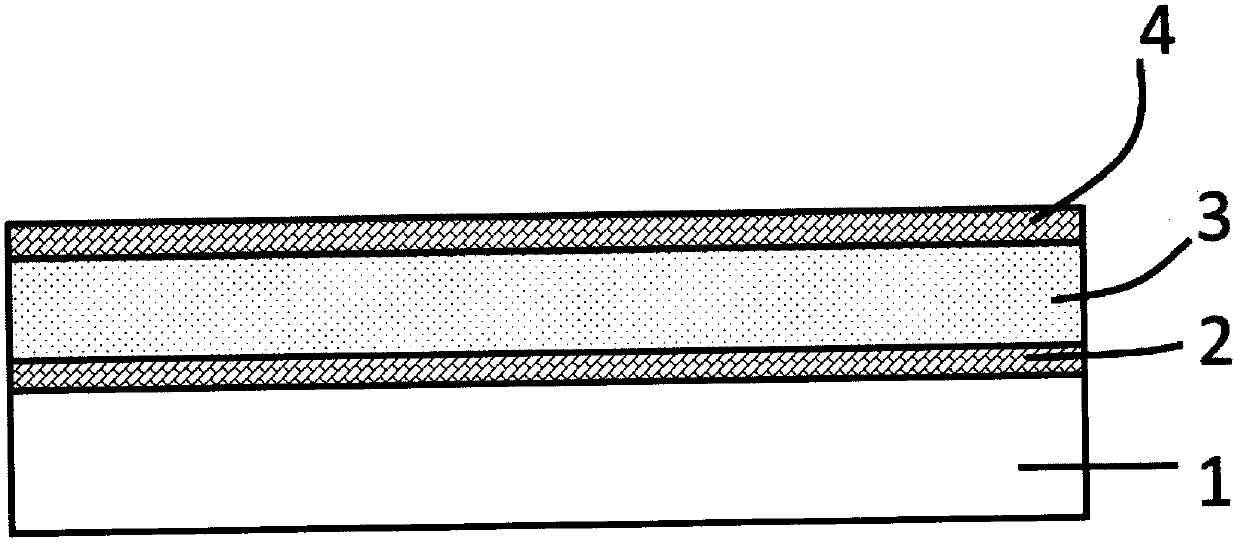

[0023] A kind of flexible transparent voltage control film capacitor of the present embodiment, see figure 1 As shown, it includes a transparent flexible substrate 1 , a bottom electrode 2 of a nano-silver fiber network, a bismuth-magnesium niobate dielectric adjustable film 3 and a top electrode 4 of a nano-silver fiber network.

[0024] In this embodiment, the transparent flexible substrate 1 is a PET sheet.

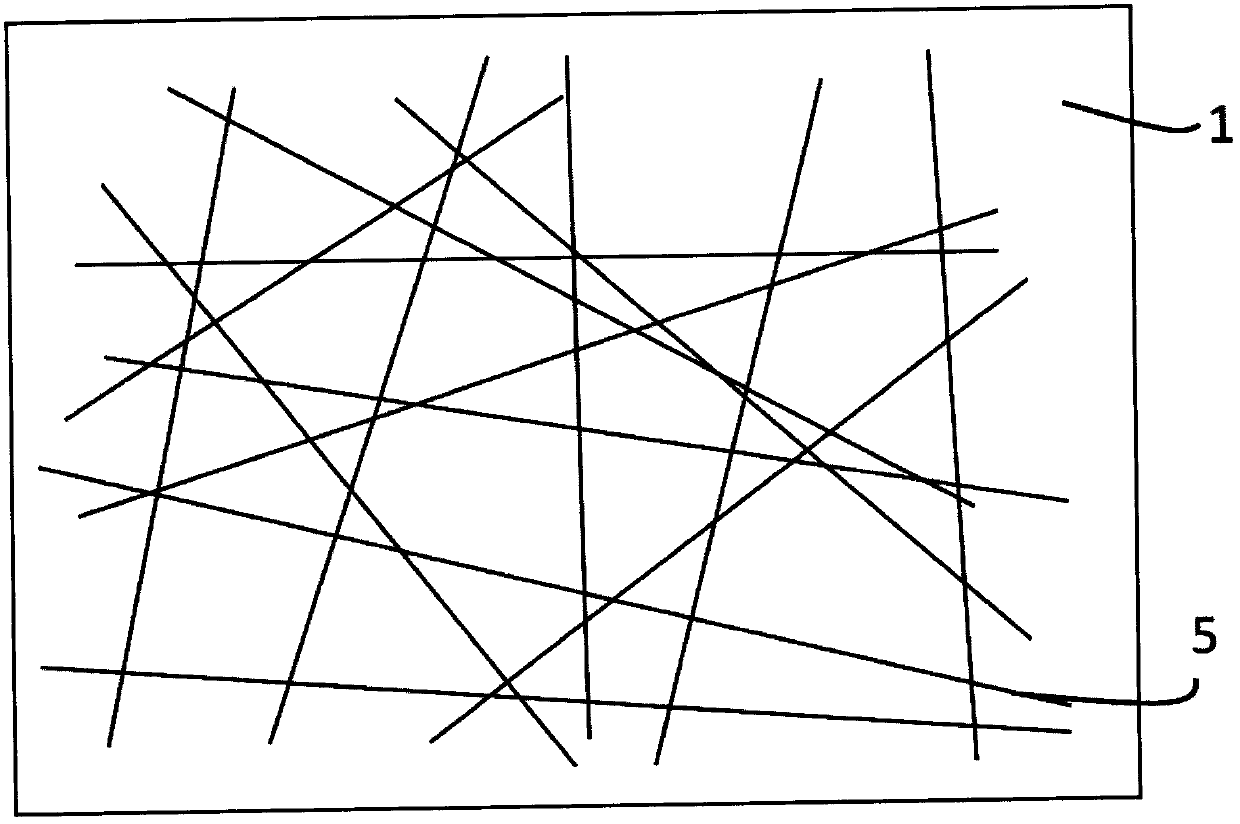

[0025] In this embodiment, the structure of the nano-silver fiber network bottom electrode 2 is shown in figure 2 As shown, the diameter of the nano silver fiber is 275nm.

[0026] In this embodiment, the dielectric adjustable film 3 of bismuth magnesium niobate has a thickness of 300nm, and the chemical formula of the bismuth magnesium niobate is Bi 1.5 MgNb 1.5 o 7 .

[0027] In this embodiment, the structure of the top electrode 4 of the nano-silver fiber network is shown in figure 2 As shown, the diameter of the nano silver fiber is 275nm.

[0028] A prepa...

Embodiment 2

[0034] A kind of flexible transparent voltage control film capacitor of the present embodiment, see figure 1 As shown, it includes a transparent flexible substrate 1 , a bottom electrode 2 of a nano-silver fiber network, a bismuth-magnesium niobate dielectric adjustable film 3 and a top electrode 4 of a nano-silver fiber network.

[0035] In this embodiment, the transparent flexible substrate 1 is a PI sheet.

[0036] In this embodiment, the structure of the nano-silver fiber network bottom electrode 2 is shown in figure 2 As shown, the diameter of the nano silver fiber is 400nm.

[0037] In this embodiment, the dielectric adjustable film 3 of bismuth magnesium niobate has a thickness of 200nm, and the chemical formula of the bismuth magnesium niobate is Bi 1.5 MgNb 1.5 o 7 .

[0038] In this embodiment, the structure of the top electrode 4 of the nano-silver fiber network is shown in figure 2 As shown, the diameter of the nano silver fiber is 400nm.

[0039] A prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com