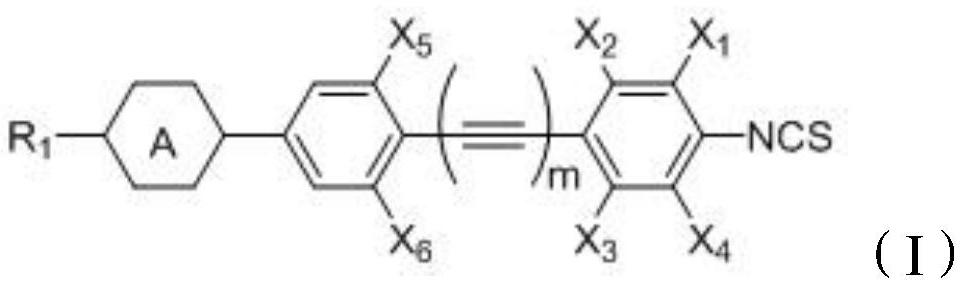

Liquid crystal compound, composition thereof and high-frequency component comprising liquid crystal compound

A technology for liquid crystal compounds and liquid crystal compositions, applied in liquid crystal materials, chemical instruments and methods, etc., can solve the problems of high dielectric loss, further improvement of comprehensive performance, low tuning rate, etc., and achieves low melting point, high tuning rate, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

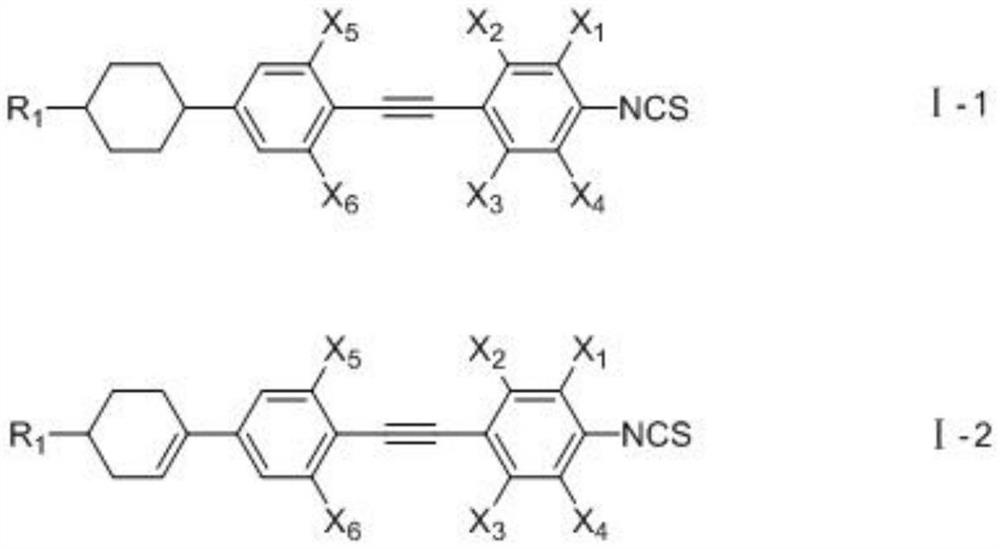

Method used

Image

Examples

Embodiment 1

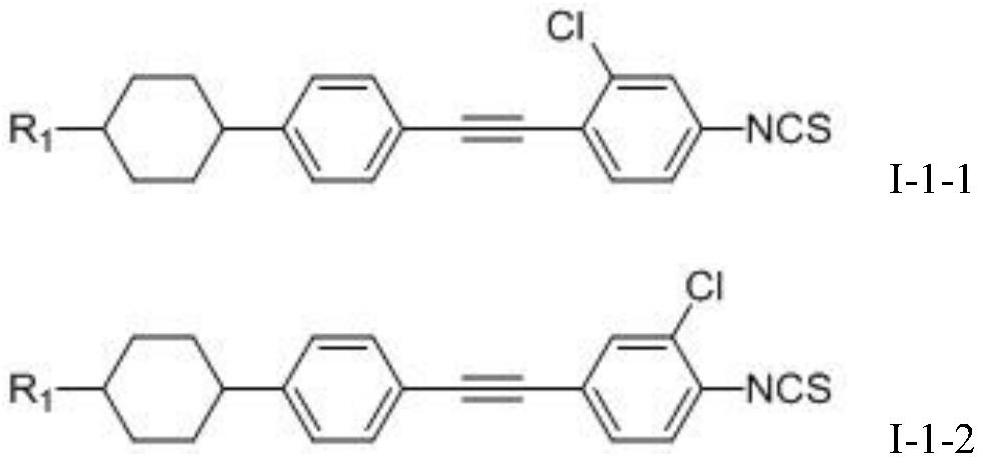

[0061] Synthesis of 2-chloro-4'-(4-propylcyclohexyl)-4-isothiocyanate-1,1'-biphenyl

[0062] The specific structure is as follows:

[0063]

[0064] The preparation process is as follows:

[0065] Step 1: Synthesis of 3-chloro-4-iodoaniline

[0066]

[0067] Add m-chloroaniline (30g, 0.235mol), iodine (179g, 0.705mol), and 500ml of water into the reaction flask, and stir at 45°C for 4.5h. After the reaction solution was lowered to room temperature, it was extracted three times with toluene, the organic phases were combined, washed with water until neutral, and the solvent was distilled off. Recrystallization gave 47 g of solid 3-chloro-4-iodoaniline with a purity of 99% and a yield of 79%.

[0068] Step 2: Synthesis of 2-chloro-4'-(4-propylcyclohexyl)-[1,1'-biphenyl]-4-amine

[0069] The specific structure is as follows:

[0070]

[0071] Add (4-(4-propylcyclohexyl)phenyl)boronic acid (6.35g, 0.0256mol), 3-chloro-4-iodoaniline (4.99g, 0.0197mol) and potassium car...

Embodiment 2

[0081] Synthesis of 2-chloro-4'-(4-ethylcyclohexyl)-4-isothiocyanate-1,1'-biphenyl

[0082] The specific structure is as follows:

[0083]

[0084] Adopt (4-(4-ethylcyclohexyl) phenyl) boronic acid to replace (4-(4-propylcyclohexyl) phenyl) boronic acid in embodiment 1 step (2), adopt the method identical with embodiment 1 2-Chloro-4'-(4-ethylcyclohexyl)-4-isothiocyanate-1,1'-biphenyl was synthesized.

Embodiment 3

[0086] Synthesis of 2-chloro-4'-(4-butylcyclohexyl)-4-isothiocyanate-1,1'-biphenyl

[0087] The specific structure is as follows:

[0088]

[0089] Using (4-(4-butylcyclohexyl) phenyl) boronic acid to replace (4-(4-propylcyclohexyl) phenyl) boronic acid in step (2) of Example 1, the same method as in Example 1 was used to synthesize 2-Chloro-4'-(4-butylcyclohexyl)-4-isothiocyanate-1,1'-biphenyl. GC purity 99.86%, yield 72%.

[0090] Structure Identification:

[0091] 1 HNMR (CDCl 3 ,500MHz)δ(ppm):0.931–0.959(t,3H),1.066–1.146(m,2H),1.272–1.407(m,7H),1.502–1.554(m,2H),1.915–1.988(m, 4H),2.507–2.583(m,1H),7.178–7.198(q,1H),7.287–7.336(m,3H),7.353–7.374(m,3H); IR(KBr,cm -1 ):2956,2920,2849,2088,1594,1544,1479,1270,1070,966,867,816,788,771,695,566.

[0092] Using DSC to test the liquid crystal phase transition temperature of 2-chloro-4'-(4-propylcyclohexyl)-4-isothiocyanate-1,1'-biphenyl at a temperature of 3°C / min, the result is : Cr43.56S54.80N 106.77I, melting point is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| isotropization temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com