Dielectric adjustable ceramic material and preparation method thereof

A ceramic material and dielectric technology, applied in the field of dielectric tunable ceramic materials and their preparation, can solve problems such as practical obstacles, unsuitability for developing dielectric tunable materials, and rising dielectric loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

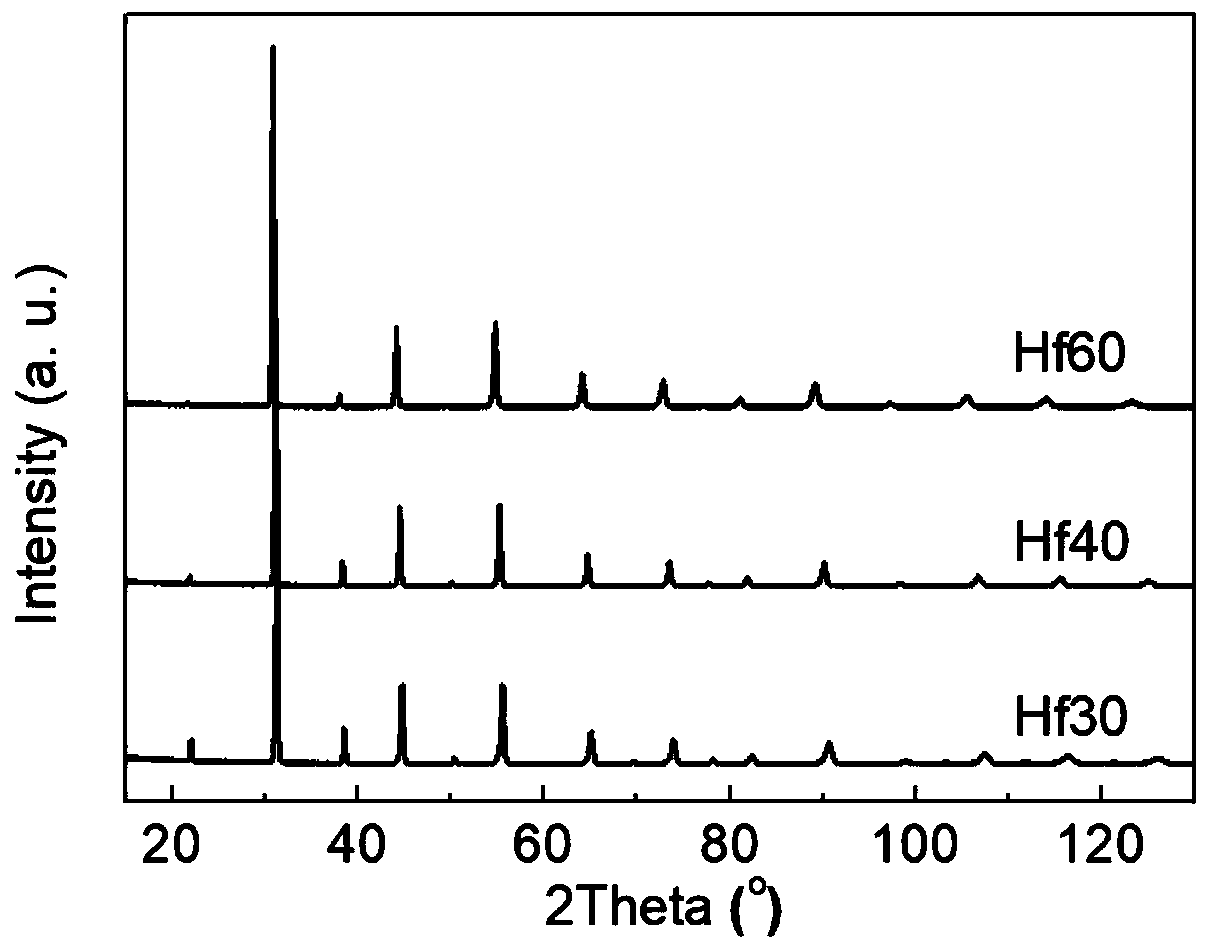

[0033] A method for preparing dielectrically adjustable ceramic materials, using a solid-state sintering process to prepare Ti-modified BaHfO 3 A perovskite type dielectric ceramic material, comprising the following steps:

[0034] Step 1. Weigh the required raw material BaCO according to the stoichiometric ratio 3 、TiO 2 and HfO 2 , and BaCO 3 、TiO 2 and HfO 2 Fully mix and grind to submicron particle size to obtain raw materials;

[0035] Step 2. Pre-press the raw material obtained in step 1 in a mold with a pressure of 100MPa-500MPa to obtain intermediate A, and then place intermediate A in a high-temperature reaction furnace and raise the temperature to 800°C-1350°C for pre-sintering , to obtain sintered product B;

[0036] Step 3. Put the sintered product B obtained in step 2 into a mortar for secondary grinding into micron-sized powder, and add a binder such as PVA for granulation, and press into a mold with a pressure of 100MPa-800MPa for tablet molding shape, t...

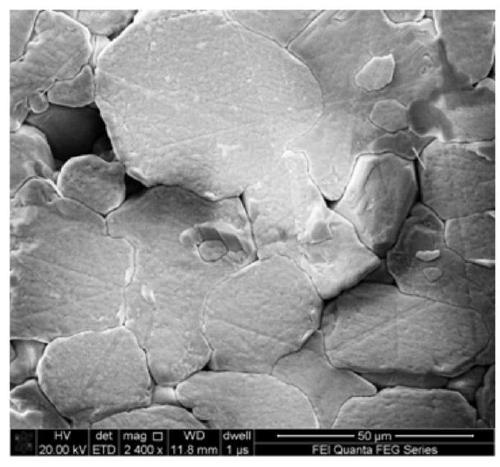

Embodiment 1

[0039] A kind of preparation method of dielectric adjustable ceramic material, chemical composition is Ba(Hf 0.3 Ti 0.7 )O 3 , referred to as Hf30. Including the following steps:

[0040] Step 1: Press Ba(Hf 0.3 Ti 0.7 )O 3 The stoichiometric ratio of each element in Weigh the required raw material: BaCO 3 、TiO 2 and HfO 2 , fully mixed and ground to obtain the original material.

[0041] Step 2: pre-press the homogeneously mixed raw material obtained above in a mold with a pressure of 500 MPa, and then place it in a high-temperature reaction furnace and raise the temperature to 1350°C for pre-sintering;

[0042] Step 3: Put the product obtained by the above pre-sintering into a mortar and grind it into a micron-sized powder, then add the binder PVA for granulation, and press the granulated granules into a mold with a pressure of 800 MPa for tablet molding;

[0043] Step 4: Put the product obtained by the above tablet molding into a high-temperature reaction furnace,...

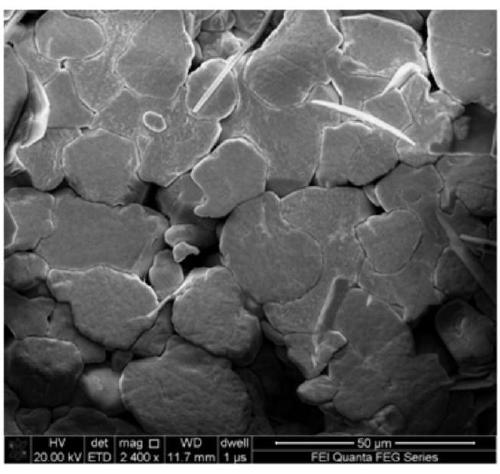

Embodiment 2

[0046] A kind of preparation method of dielectric adjustable ceramic material, chemical composition is Ba(Hf 0.4 Ti 0.6 )O 3 , referred to as Hf40. Including the following steps:

[0047] Step 1: Press Ba(Hf 0.4 Ti 0.6 )O 3 The stoichiometric ratio of each element in Weigh the required raw material: BaCO 3 、TiO 2 and HfO 2 , fully mixed and ground to obtain the original material.

[0048] Step 2: pre-press the uniformly mixed raw materials obtained above in a mold with a pressure of 100 MPa to obtain intermediate A1, and then place intermediate A1 in a high-temperature reaction furnace and raise the temperature to 800°C for pre-sintering;

[0049] Step 3: Put the above-mentioned pre-sintered product into a micron-sized powder for the second time in a mortar, add the binder PVA for granulation, and perform tablet molding with a pressure of 100 MPa in the mold;

[0050] Step 4: Put the product obtained by the above-mentioned tablet molding into a high-temperature react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

| dielectric loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com