Anti-deformation co-combustion sintering fixture and material thereof

A technology for jigs and sintered workpieces, which is applied in the field of jigs, and achieves the effects of large shrinkage, reduced sliding friction for demoulding, and reduced manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

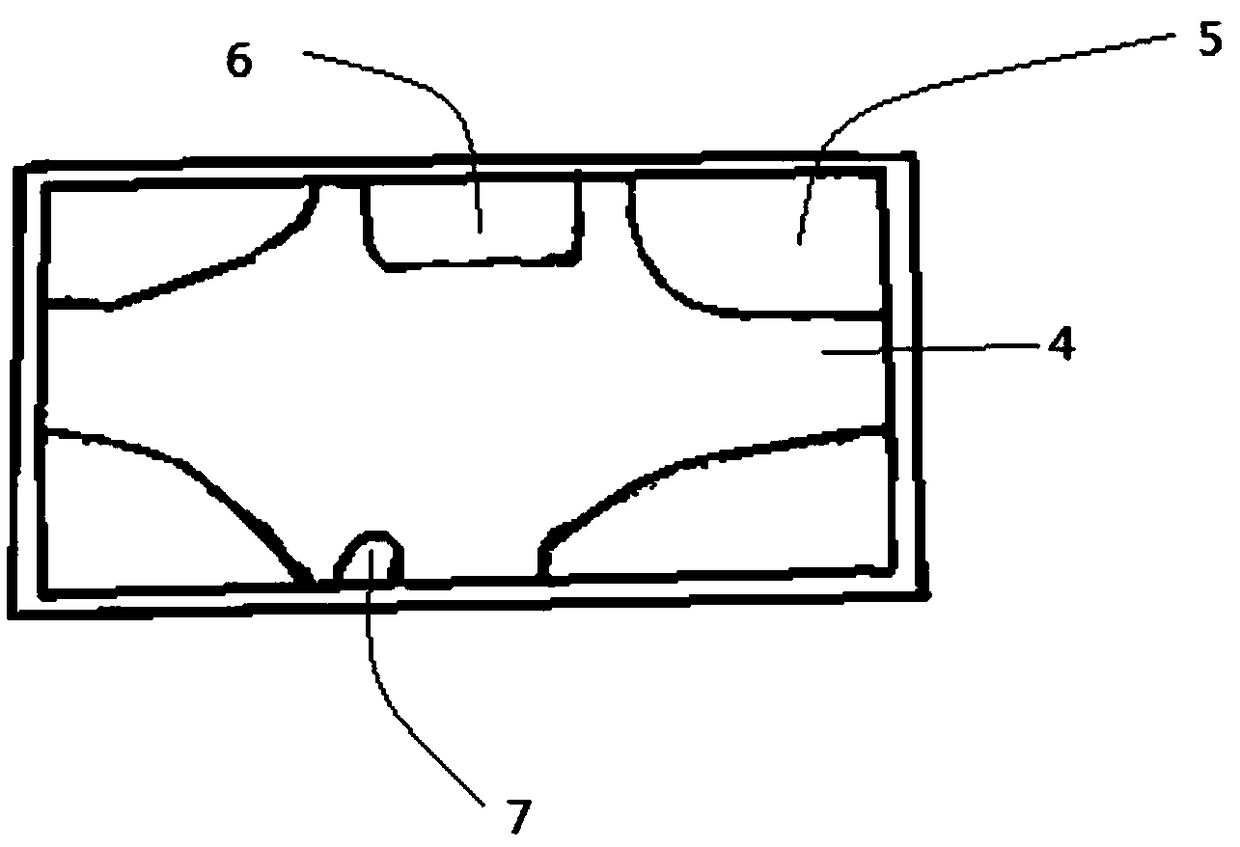

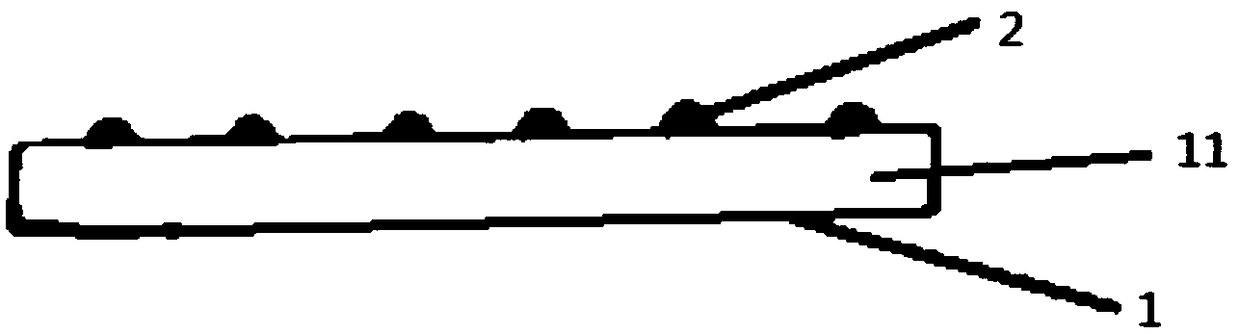

Embodiment 1

[0028] Embodiment 1: The anti-deformation sintering jig provided in this embodiment includes a substrate 1, the substrate includes a base 11 and an assembly structure 12 that is in contact with the surface of the workpiece 4 to be sintered, wherein the workpiece to be sintered can be a titanium alloy watch case , the preferred cross-section of the base 11 is a rectangle, and the assembly structure 12 is a plurality of bumps 2 or a plurality of grooves 3. When the plurality of bumps are hemispherical bumps, the adjacent bumps are arranged at equal intervals. When a plurality of grooves are all trapezoidal grooves, adjacent grooves are arranged at equal intervals. Among them, the convex point or groove structure can play the role of exhaust support and reduce friction. The material shrinkage rate of the anti-deformation sintering fixture is the same or similar to that of the surface of the workpiece to be sintered, and the sintering temperature of the material of the anti-deform...

Embodiment 2

[0030]Embodiment 2: It is basically the same as Embodiment 1, the difference is that the material of a kind of anti-deformation sintering fixture with firing in this embodiment is made of components including the following weight percentages: 50% powder, water-soluble 14.5% of polyester, 20% of polypropylene, 10% of fatty acid amide phosphate, 5% of coupling agent polypropylene grafted acrylic acid, 0.3% of stabilizer calcium laurosilicate, and 0.2% of antioxidant BHT. The powder includes the following components in parts by weight: 20 parts of silicon powder, 6 parts of stainless steel powder, and 38 parts of alumina ceramic powder.

Embodiment 3

[0031] Embodiment 3: It is basically the same as Embodiment 1, the difference is that the material of a kind of anti-deformation sintering fixture with firing in this embodiment is made of components including the following weight percentages: powder 60%, water-soluble 10% polyester, 16.3% polypropylene, 10% fatty acid amide phosphate, 3% isopropyl dihexadecyl borate as a coupling agent, 0.3% sodium stearate as a stabilizer, and 1680.4% antioxidant. The powder includes the following components in parts by weight: 12 parts of silicon powder, 8 parts of stainless steel powder, and 35 parts of alumina ceramic powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com