Efficient, low-cost and pollution-free preparing method of polymer hydrophobic surfaces

A hydrophobic surface, low-cost technology, applied in the micro-nano field, can solve the problems of unfavorable operator's health, high equipment requirements, and high cost, and achieve the effect of being beneficial to health, broad application prospects, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

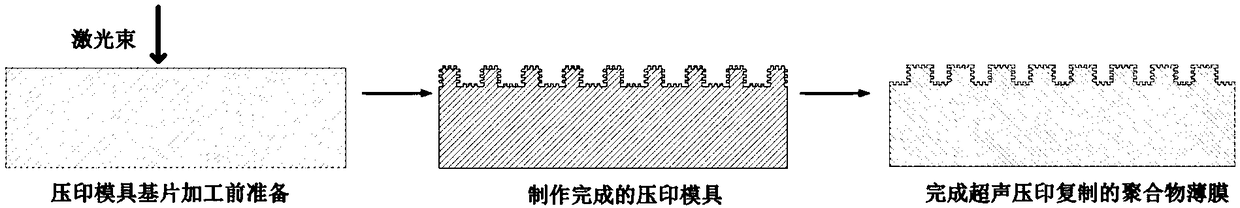

[0026] see Figure 1 to Figure 5 , a method for preparing a polymer hydrophobic surface with high efficiency, low cost and pollution-free, adopts the following steps:

[0027] 1) Make imprint mold

[0028] 1.1) Use plates to make mold substrates;

[0029] 1.2) Clean the mold substrate and then dry it;

[0030] 1.3) Using laser processing equipment to process the microstructure pattern on the surface of the mold substrate;

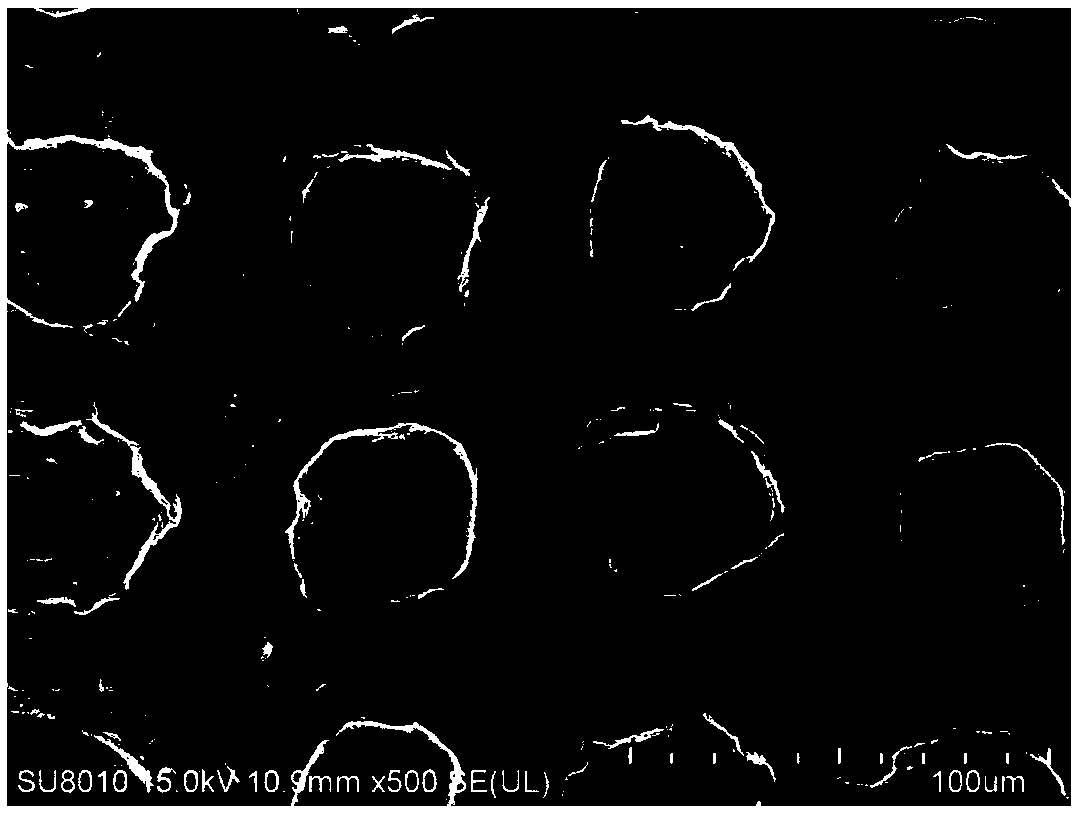

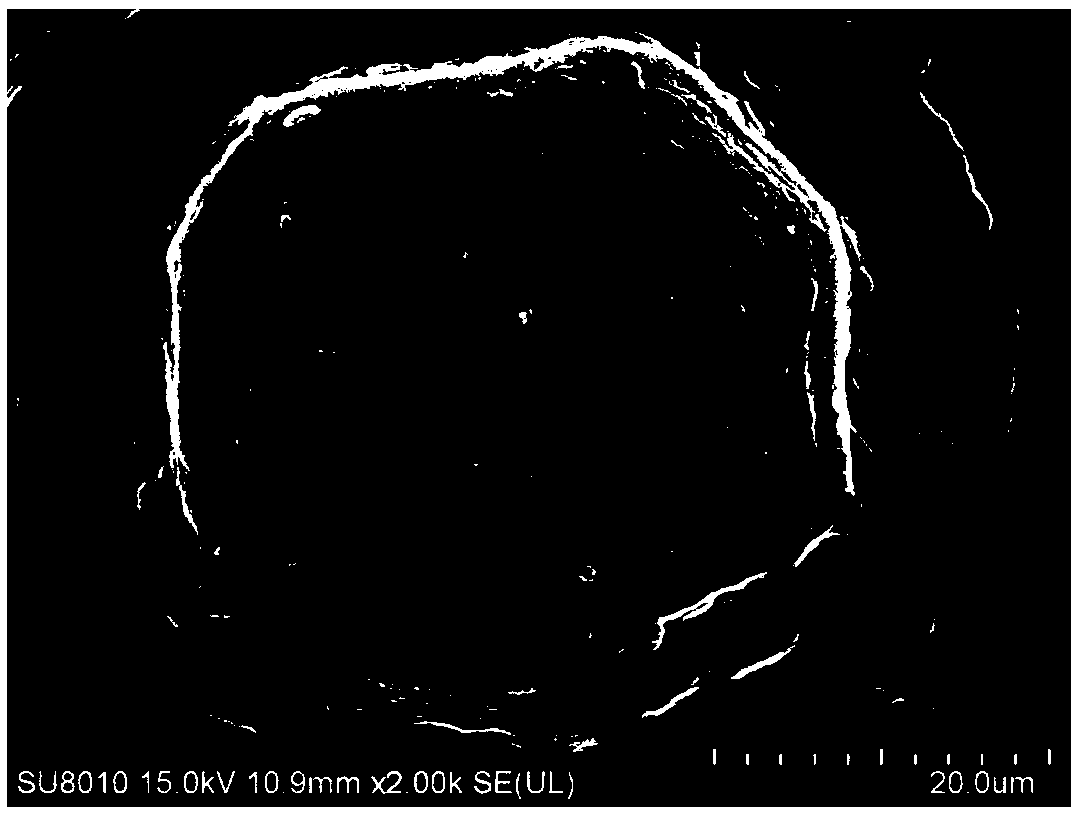

[0031] 2) Ultrasonic imprinting equipment is used, and the imprinting mold made in step 1) is used to perform ultrasonic imprinting replication on the polymer film to obtain a hydrophobic surface with a micro-nano dual structure.

[0032] In this embodiment, in the step 1.1), the mold substrate is made of an aluminum p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com