Modified urea-formaldehyde resin adhesive for outdoor fiberboard and preparation method thereof

A technology of urea-formaldehyde resin and fiberboard, applied in the direction of non-polymer adhesive additives, applications, household components, etc., can solve the problems of unbearable production enterprises, markets and consumers, low production efficiency, high cost, etc., and achieve adhesive bonding Good performance, low cost, and the effect of improving the bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

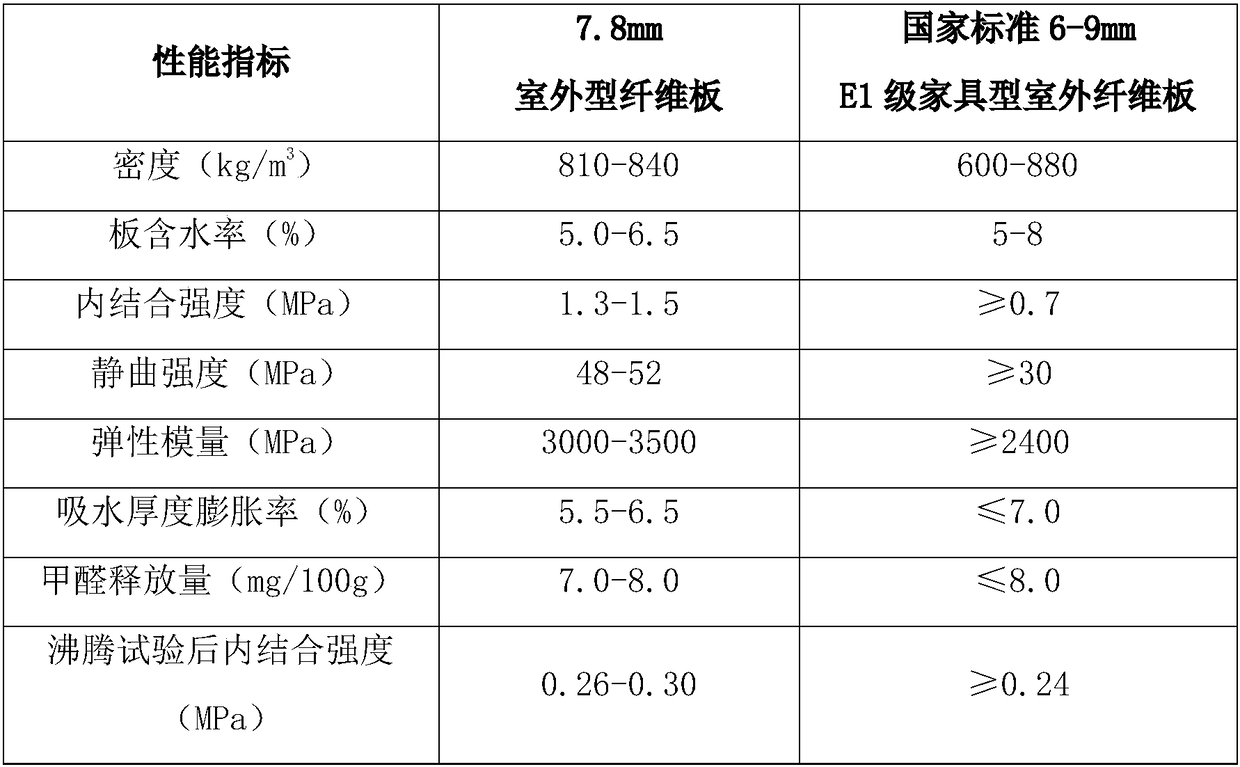

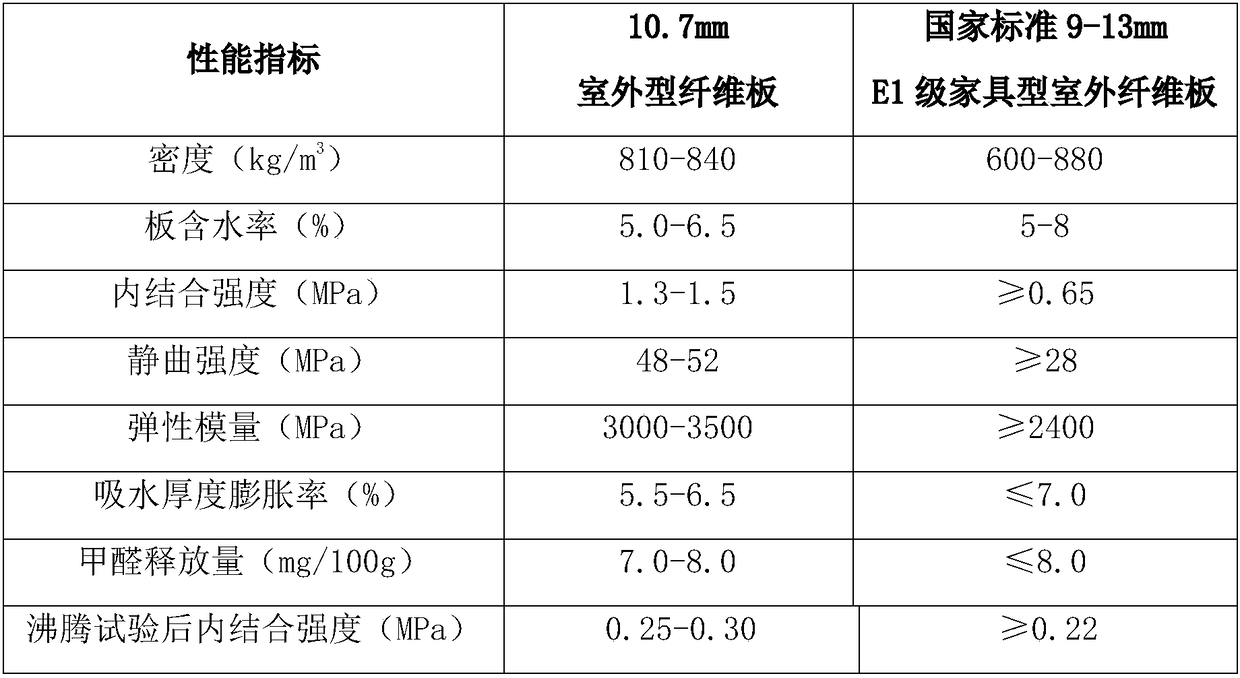

Image

Examples

Embodiment 1

[0025] 1. A melamine-phenol modified urea-formaldehyde resin for outdoor fiberboards, comprising the following raw materials in parts by mass: 57 parts of formaldehyde (37% content), 10 parts of melamine, 28 parts of urea, and 5 parts of phenol.

[0026] 2. A melamine-phenol modified urea-formaldehyde resin adhesive for outdoor fiberboards, comprising the following raw materials in parts by mass: melamine, 93 parts of phenol-modified urea-formaldehyde resin, 5 parts of isocyanate prepolymer, and 2.0 parts of ammonium sulfate.

Embodiment 2

[0028] 1. A melamine-phenol modified urea-formaldehyde resin for outdoor fiberboards, comprising the following raw materials in parts by mass: 52 parts of formaldehyde (37% content), 11 parts of melamine, 31 parts of urea, and 6 parts of phenol.

[0029] 2. A melamine-phenol modified urea-formaldehyde resin adhesive for outdoor fiberboards, comprising the following raw materials in parts by mass: melamine, 90 parts of phenol-modified urea-formaldehyde resin, 8 parts of isocyanate prepolymer, and 1.5 parts of ammonium sulfate.

Embodiment 3

[0031] 1. The weight and parts of melamine-phenol modified urea-formaldehyde resin for outdoor fiberboard are: 51 parts of formaldehyde (37% content), 12 parts of melamine, 30 parts of urea, and 7 parts of phenol.

[0032] 2. The weight and parts of a melamine-phenol-modified urea-formaldehyde resin adhesive for outdoor fiberboards are: 89 parts of melamine and phenol-modified urea-formaldehyde resin, 10 parts of isocyanate prepolymer, and 1.0 part of ammonium sulfate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com