A kind of lubricating oil film level measuring instrument and measuring method thereof

A technology of lubricating oil and measuring instrument, applied in instruments, measuring devices, scientific instruments, etc., can solve problems such as poor boundary lubrication of PAO

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] This embodiment discloses a lubricating oil film level measuring instrument, which is suitable for performing each method step described in the present invention, so as to achieve expected technical effects. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

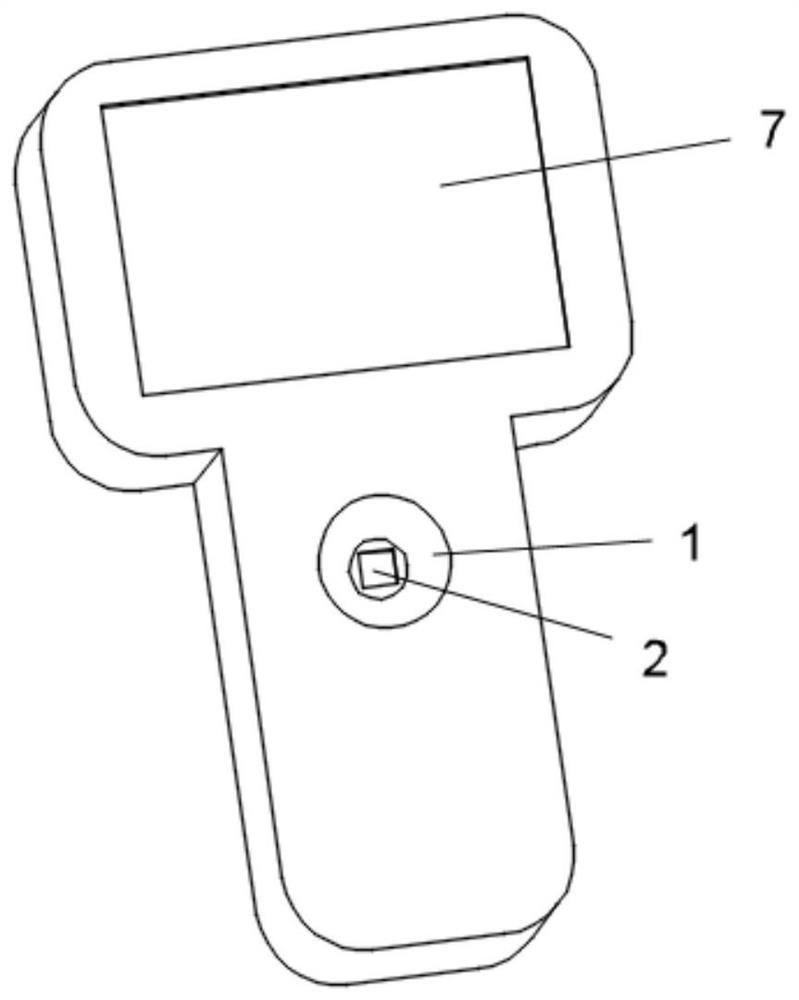

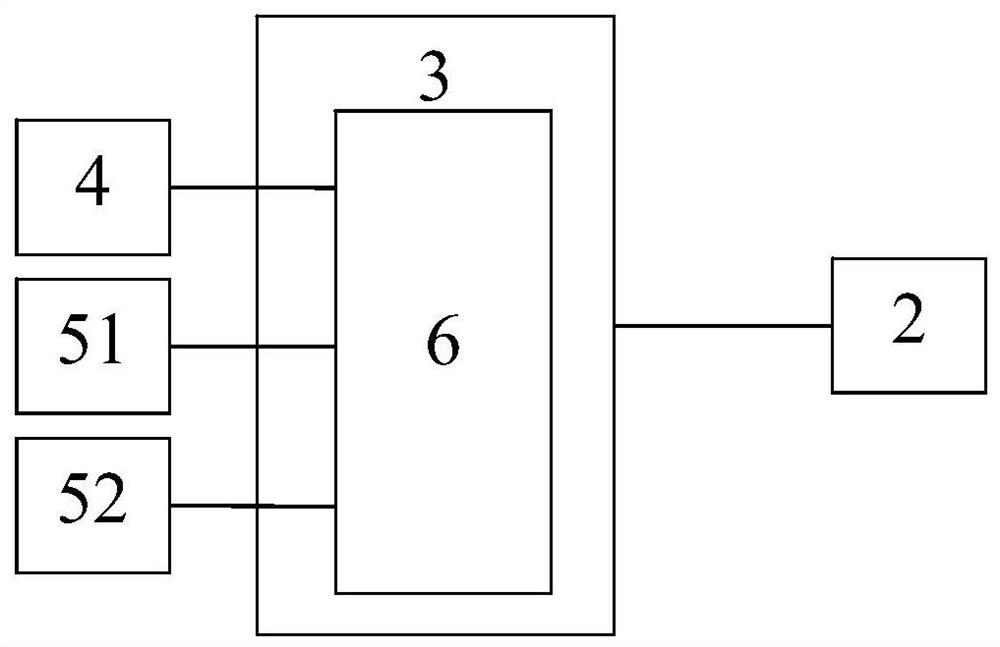

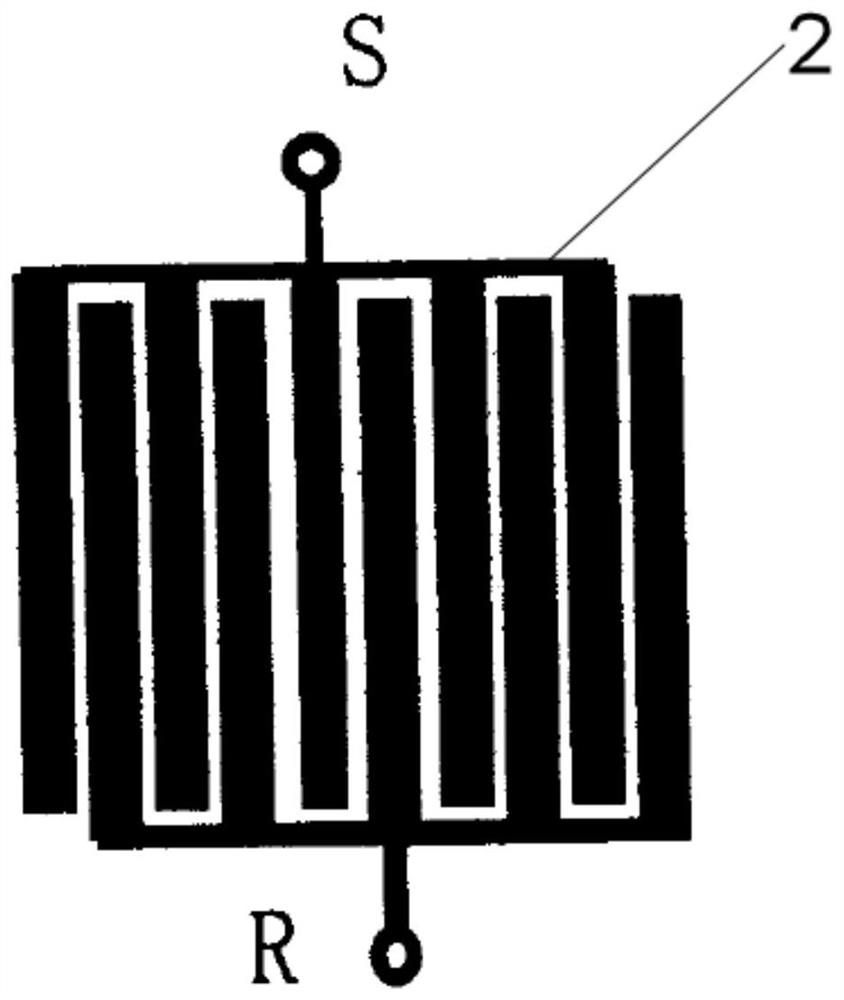

[0025] According to a preferred embodiment, see figure 1 , 2 , the lubricating oil film level detector may include a capacitive sensor 2 arranged in the oil tank 1 , a measuring module 3 connected to the capacitive sensor 2 and a processor 6 connected to the measuring module 3 . Preferably, the measurement module 3 may also include an operational amplifier and an analog-to-digital converter. Since the output signals and their differences generated by different lubricating oil compositions are very small, they can be amplified by a DC amplifier circuit, and then converted into digital ...

Embodiment 2

[0037]This embodiment may be a further improvement and / or supplement to Embodiment 1, and repeated content will not be repeated here. This embodiment also discloses a method for measuring the oil film level of lubricating oil, which can be realized by the lubricating oil film level measuring instrument of the present invention and / or other replaceable components. For example, the method of the present invention is realized by using each component in the lubricating oil film level tester of the present invention. In the case of no conflict or contradiction, the whole and / or part of the content of the preferred implementations of other embodiments may serve as supplements to this embodiment.

[0038] According to a preferred embodiment, a method for determining the level of lubricating oil film, the method may include: using a capacitive sensor 2 arranged in the oil tank 1 and a measurement module 3 connected to the capacitive sensor 2, wherein the measurement module 3 may inclu...

Embodiment 3

[0053] This embodiment may be a further improvement and / or supplement to Embodiment 1, 2 or their combination, and repeated content will not be repeated.

[0054] In this embodiment, an optional process of measuring the oil film level of gasoline engine oil is taken as an example.

[0055] Continuously short press the confirmation button 3 times;

[0056] The interface displays gasoline engine oil, diesel engine oil, transmission oil and hydraulic oil;

[0057] Select the gasoline engine oil product by touching the buttons up, down, left, and right;

[0058] Press the confirm button;

[0059] The words please put in synthetic oil appear;

[0060] Use a glass rod or a pipette to drop 3-4 drops of calibration oil whose oil film level is selected as 100% into the oil tank;

[0061] Press the confirm button;

[0062] The words in calibration appear;

[0063] After the calibration is completed, the words "Calibration Complete" will appear, and the words "Please put in the bas...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com