An organic electroluminescent device

An electroluminescent device and a luminescent technology, applied in the direction of electric solid-state devices, electrical components, semiconductor devices, etc., can solve the problems of fast device efficiency roll-off, short luminous life, etc., and achieve reduced efficiency roll-off phenomenon and high luminous efficiency , the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

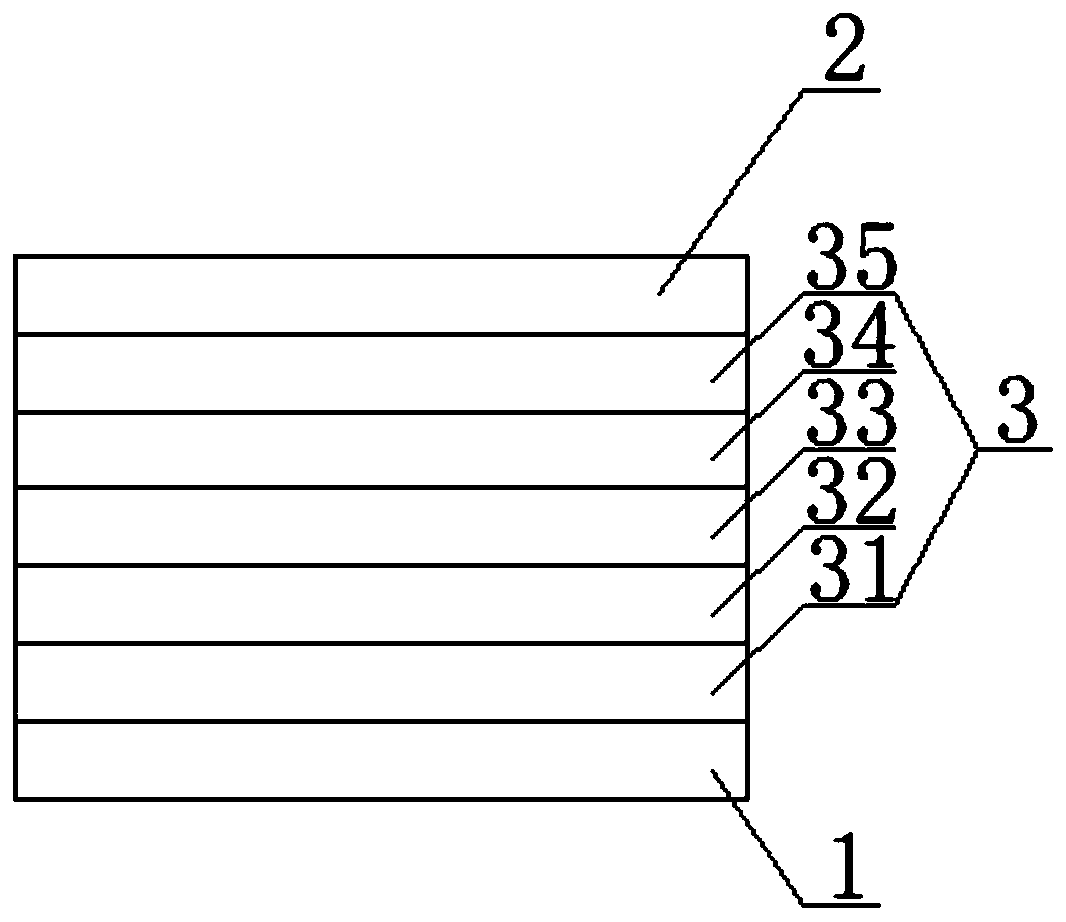

[0063] This embodiment provides an organic electroluminescent device, such as figure 2 As shown, it includes a first electrode 1, a second electrode 2, and an organic functional layer 3 located between the first electrode 1 and the second electrode. Among them, the first electrode 1 is an anode, the second electrode 2 is a cathode, and the organic functional layer 3 includes a hole injection layer 31, a hole transport layer 32, a light emitting layer 33, an electron transport layer 34 and Electron injection layer 35.

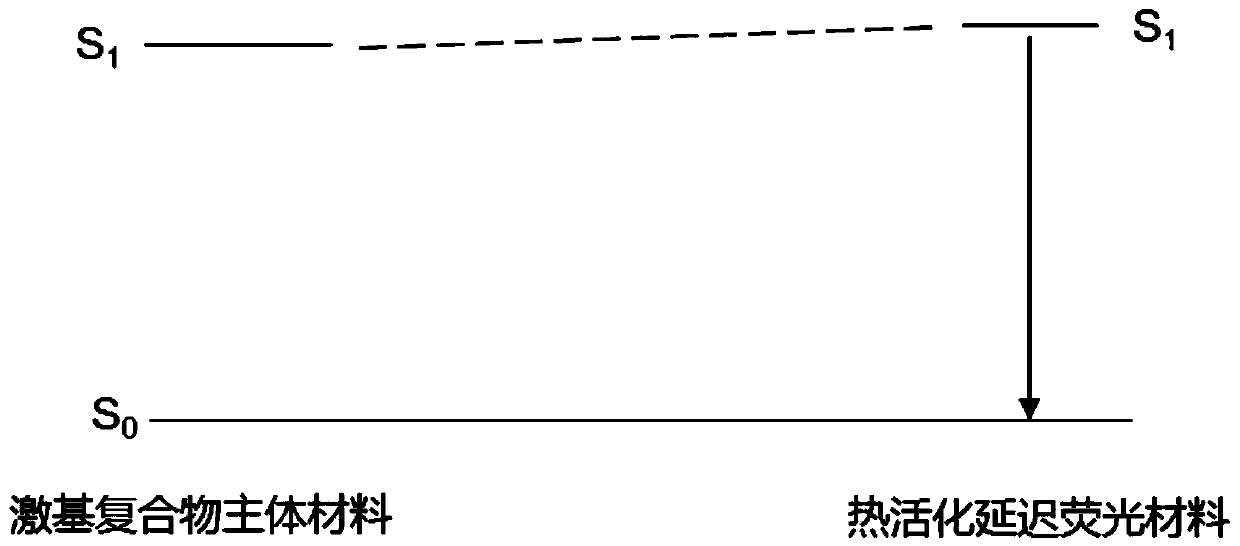

[0064] The light-emitting layer 33 is composed of a host material doped with a guest material. The host material is an exciplex with electron transport properties and hole transport properties, and the guest material is a thermally activated delayed fluorescent material. The doping ratio of the thermally activated delayed fluorescent material is (The ratio of the mass of the thermally activated delayed fluorescent material to the total mass of the light-emitting l...

Embodiment 2

[0080] This embodiment provides an organic electroluminescence device. The structure of the organic electroluminescence device is the same as that of embodiment 1. The difference between the organic electroluminescence device and the organic electroluminescence device provided in embodiment 1 is only: the formation of exciplex The mass ratio of the electron donor material (D-20) and the electron acceptor material (A-30) is 7:3. The organic electroluminescent device has the following device structure:

[0081] ITO / HATCN(5nm) / NPB(30nm) / TCTA(10nm) / 63wt%(D-20): 27wt%(A-30): 10wt%(T-3)(30nm) / 50wt% DpyPA: 50wt% Liq(30nm) / LiF(0.5nm) / Al(150nm).

[0082] The singlet energy level of the exciplex is 2.86 eV, and the singlet energy level of the thermally activated delayed fluorescent material (T-3) is 2.90 eV.

Embodiment 3

[0084] This embodiment provides an organic electroluminescence device. The structure of the organic electroluminescence device is the same as that of embodiment 1. The difference between the organic electroluminescence device and the organic electroluminescence device provided in embodiment 1 is only: the main body of the light-emitting layer 33 The material is electron donor material (D-20) and electron acceptor material (A-19) to form exciplex, the mass ratio of electron donor material (D-20) and electron acceptor material (A-19) is 1:1; the doping ratio of the thermally activated delayed fluorescent material (T-3) as the guest material in the light-emitting layer 33 is 20 wt%. The organic electroluminescent device has the following device structure:

[0085] ITO / HATCN(5nm) / NPB(30nm) / TCTA(10nm) / 40wt%(D-20):40wt%(A-19):20wt%(T-3)(30nm) / 50wt%DpyPA:50wt% Liq(,30nm) / LiF(0.5nm) / Al(150nm).

[0086] The singlet energy level of the exciplex is 2.86 eV, and the singlet energy level of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com