Lithium-ion battery material surface coating conductive layer and preparation method thereof

A lithium-ion battery, surface coating technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of core expansion, uneven mixing, etc., to reduce usage, reduce baking time, and uniform coating. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

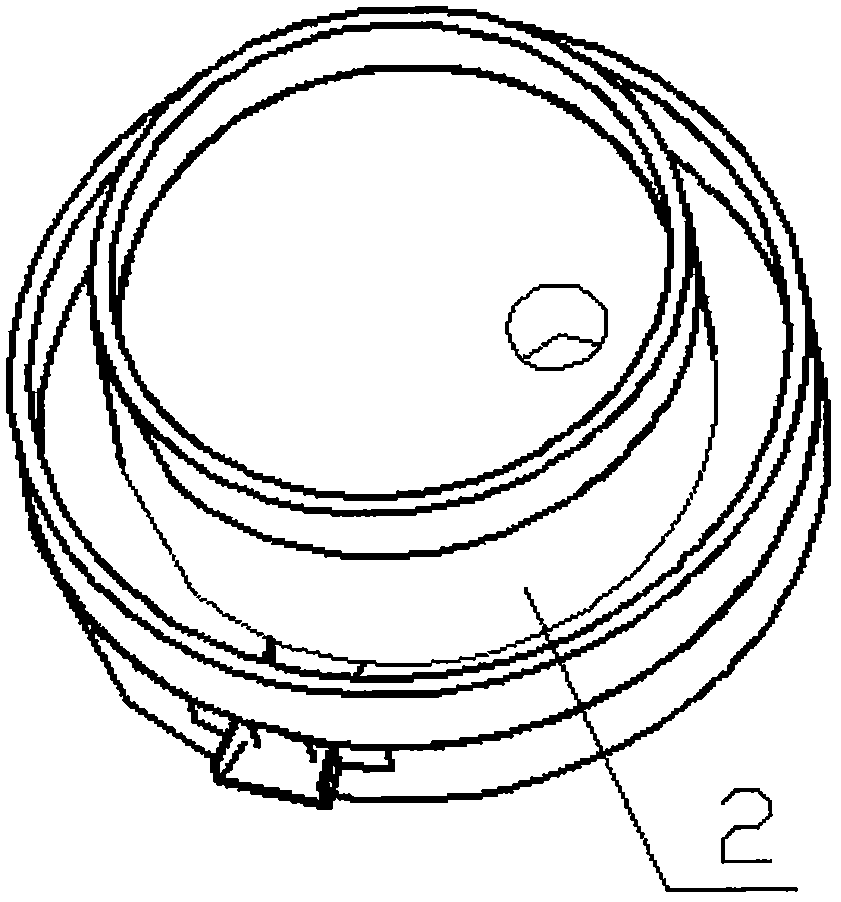

[0017] A kind of lithium ion battery material surface coated conductive layer and its preparation method, as attached Figure 1-Figure 7 As shown, the surface mill 2 is composed of an upper grinding plate 3, a lower grinding plate 4, an upper grinding plate stainless steel ring 5, and a lower grinding plate stainless steel ring 6. The upper grinding plate 3 is cylindrical, and the upper grinding plate 3 There is a feed inlet, and an upper grinding plate stainless steel ring 5 is installed above the upper grinding plate 3 of the surface mill 2. There is an annular plane at the bottom of the upper grinding plate 3, and the annular plane is parallel to the lower grinding plate 4. There is a conical surface between the annular plane and the feed inlet. The present invention adopts natural flake graphite, high-purity artificial graphite or various carbon conductive agents to make a conductive material plate 1, and the thickness of the conductive material plate 1 is 30mm. The materi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com