Multi-station sheet loading device and punching production line

A multi-station, blank technology, applied in the direction of positioning device, feeding device, storage device, etc., can solve the problems of unfavorable efficient use of workshop space, large area occupied by the feeding device, high cost, etc., and achieve the switching of the feeding position mode Rapid, simple feeding method and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

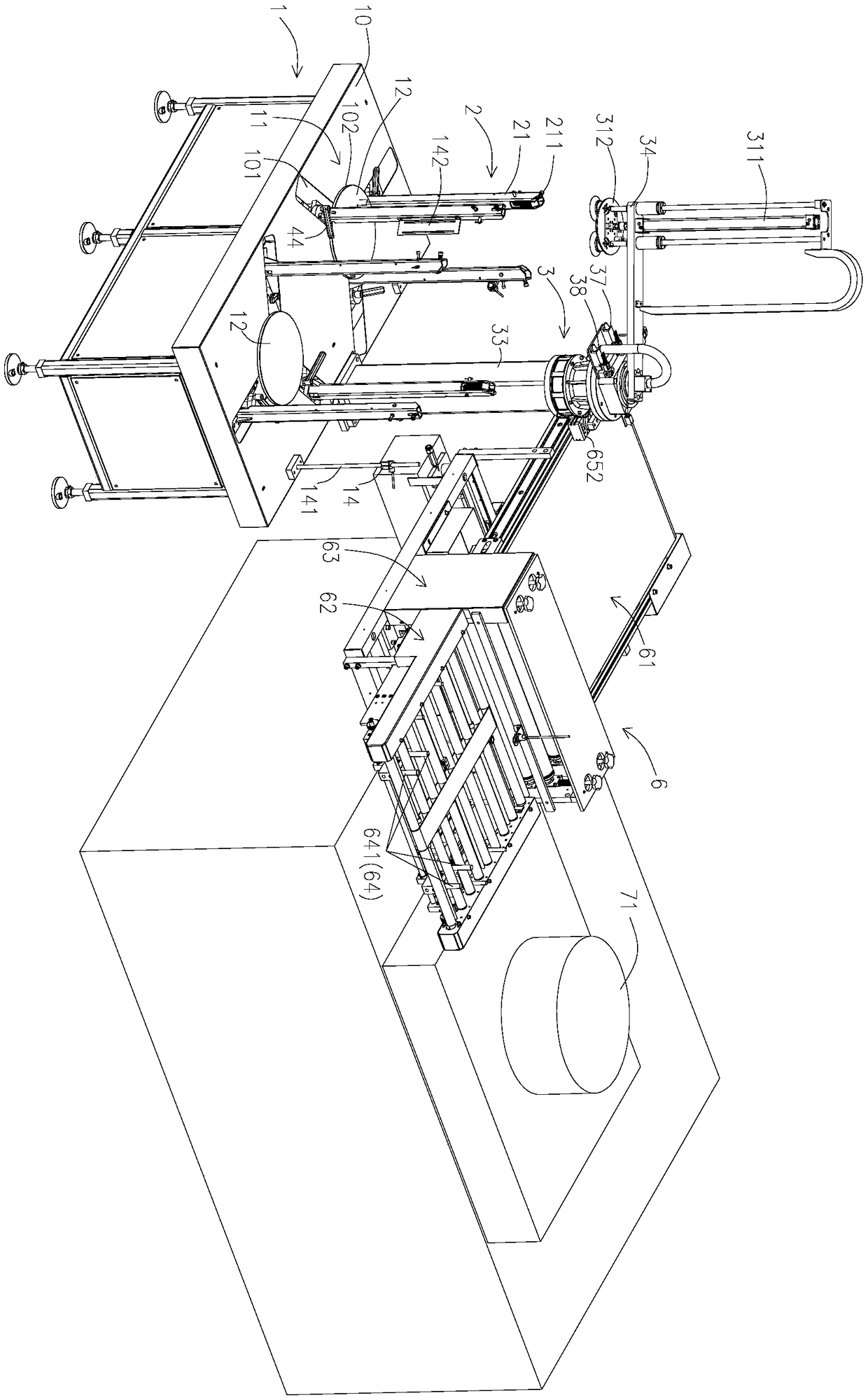

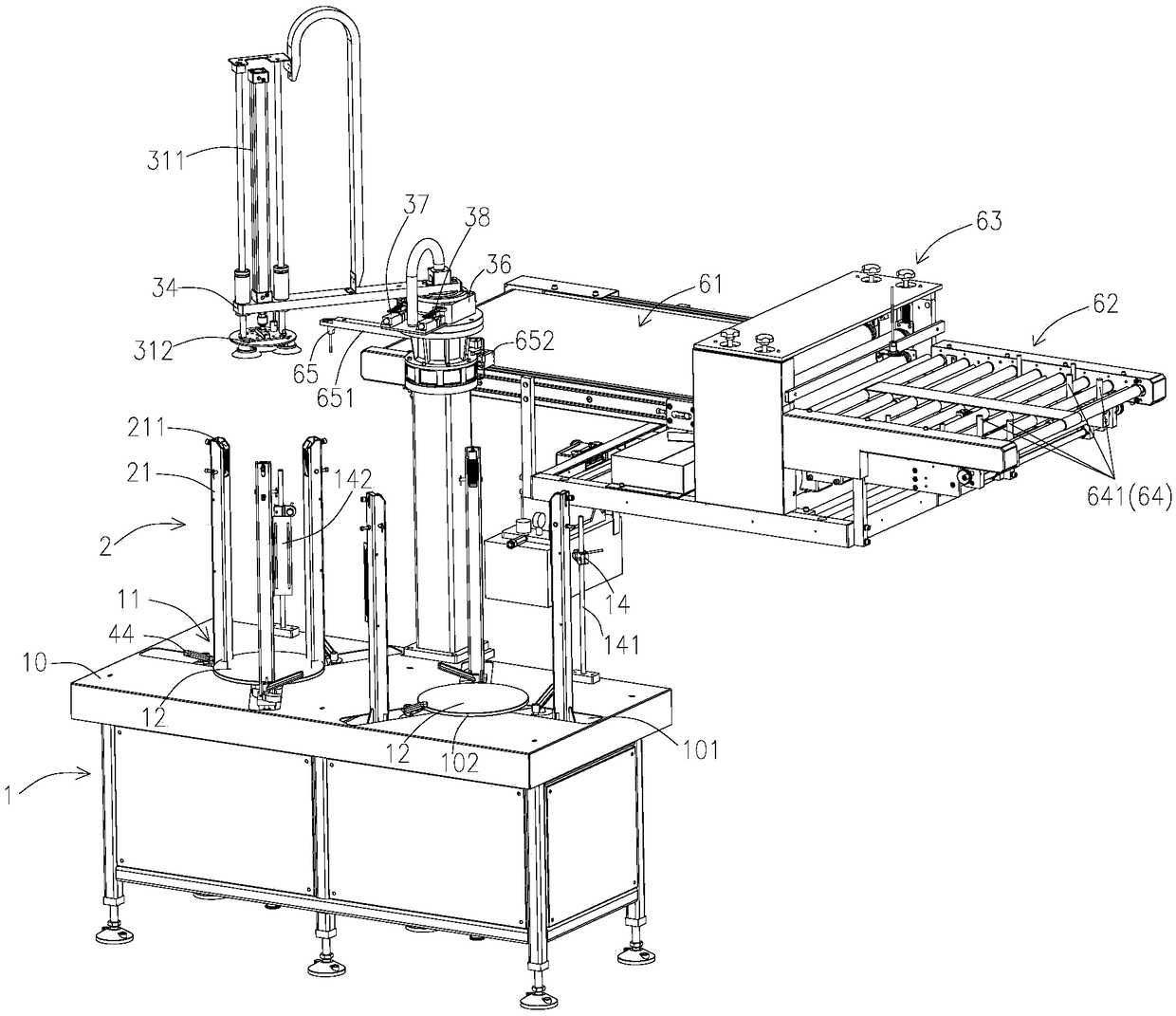

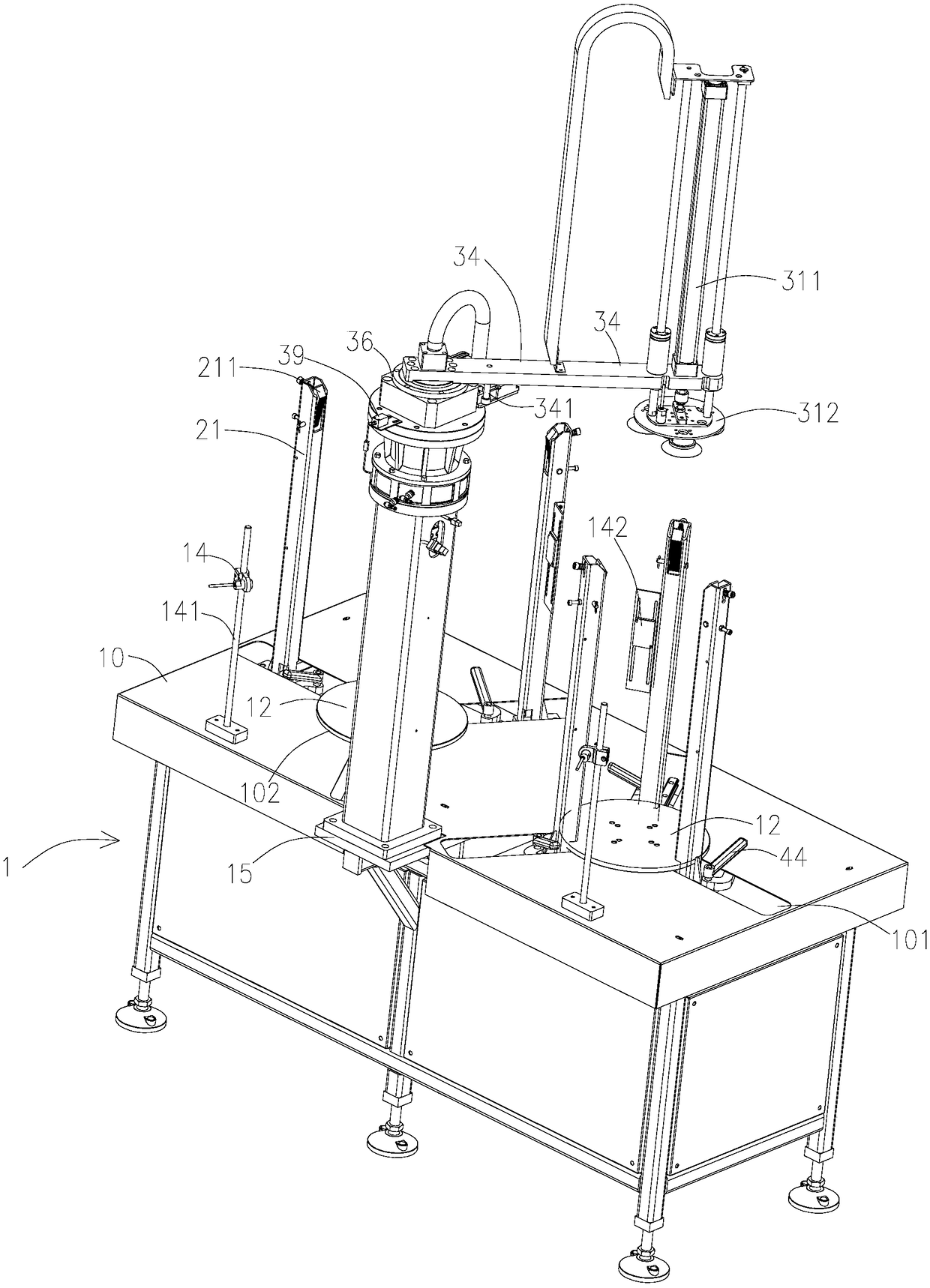

[0032] see Figures 2 to 6 , the multi-station tablet feeding device of the present invention comprises a frame 1, a manipulator 3 and at least two discharging mechanisms 11 arranged on the frame 1 for placing tablets, the manipulator 3 includes a main body 33, a rotatable The swing arm 34 on the top of the main body 33 and the sucker 312 at the end of the swing arm 34, the main body 33 is provided with a rotary drive mechanism 32 for driving the swing arm 34 to rotate, and the swing arm 34 is provided with a drive sucker 312 to reciprocate vertically The moving take-up drive mechanism 311, each discharge mechanism 11 is arranged on the trajectory that the sucker 312 rotates with the swing arm 34; Switching between positions, the reclaiming drive mechanism 311 drives the suction cup 312 to move vertically to reclaim the material on the discharge mechanism 11. When the machine is in the process of continuously retrieving materials from one of the discharge mechanisms 11, the ot...

Embodiment 2

[0066] The main difference between this embodiment and Embodiment 1 is that: the rotary drive mechanism 3 includes a gear 301 and a rack 302 that mesh with each other, and a linear drive device 303 that is transmission-connected to the rack 302; the swing arm 34 and the gear 301 is arranged laterally on the main body 33, the head end of the swing arm 34 is synchronously connected with the gear 301, the rotation axis of the head end of the swing arm 34 coincides with the rotation axis of the gear 301, and the front and back of the linear drive device 303 Drive rack 302 can make described gear 301 reciprocating rotation, thereby make described swing arm 34 swing sucker 312 to switch between above each discharge mechanism 11 and target position; In the present embodiment, described linear drive device 303 can be an air cylinder, a hydraulic cylinder or other types of linear drive devices. By setting the stroke of the telescopic rod of the linear drive device 303 to control the swi...

Embodiment 3

[0069] see Figures 1 to 7 , the main purpose of this embodiment is to provide a stamping production line using Embodiment 1, which includes stamping equipment (not shown in the figure), oiling equipment 6, handling manipulator 3 (not shown in the figure) and Embodiment 1 The multi-station blank feeding device, the stamping equipment includes a stamping upper die and a stamping lower die 71, and the oiling equipment includes a first conveying mechanism 61, a second conveying mechanism 62, and is located on the first conveying mechanism 61 and the oiling mechanism 63 between the second conveying mechanism 62, the second conveying mechanism 62 is provided with a centering positioning mechanism 64 for centering and positioning the tablet, and the centering positioning mechanism 64 includes two groups that can be opposite or The pushing column 641 that moves in reverse, the target position is the first conveying mechanism 61, and the first conveying mechanism 61 conveys the materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com