A method for smooth surface forming of preset edge holes in weakly bonded and multi-fissure water-rich rock roadway

A weak bonding and edge technology, applied in mining equipment, earthwork drilling, shaft equipment, etc., can solve the problems of poor roadway section forming, roof caving, associated cutting and falling, etc., to achieve good roadway forming, avoid roof caving, technology simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

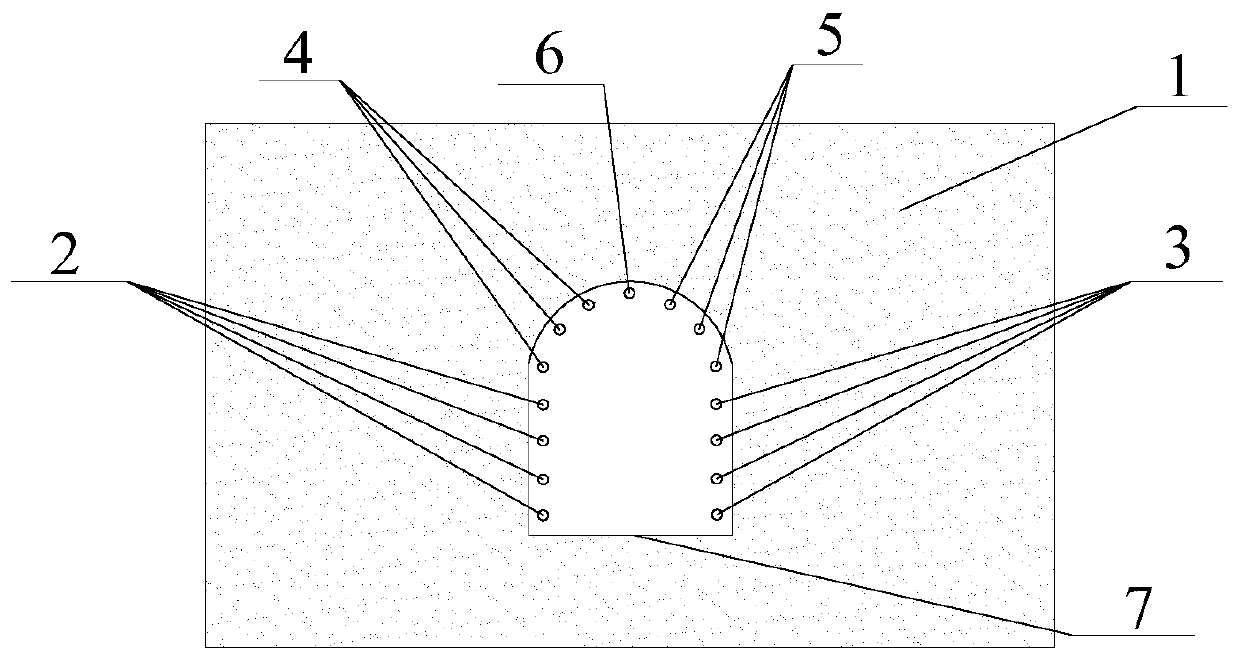

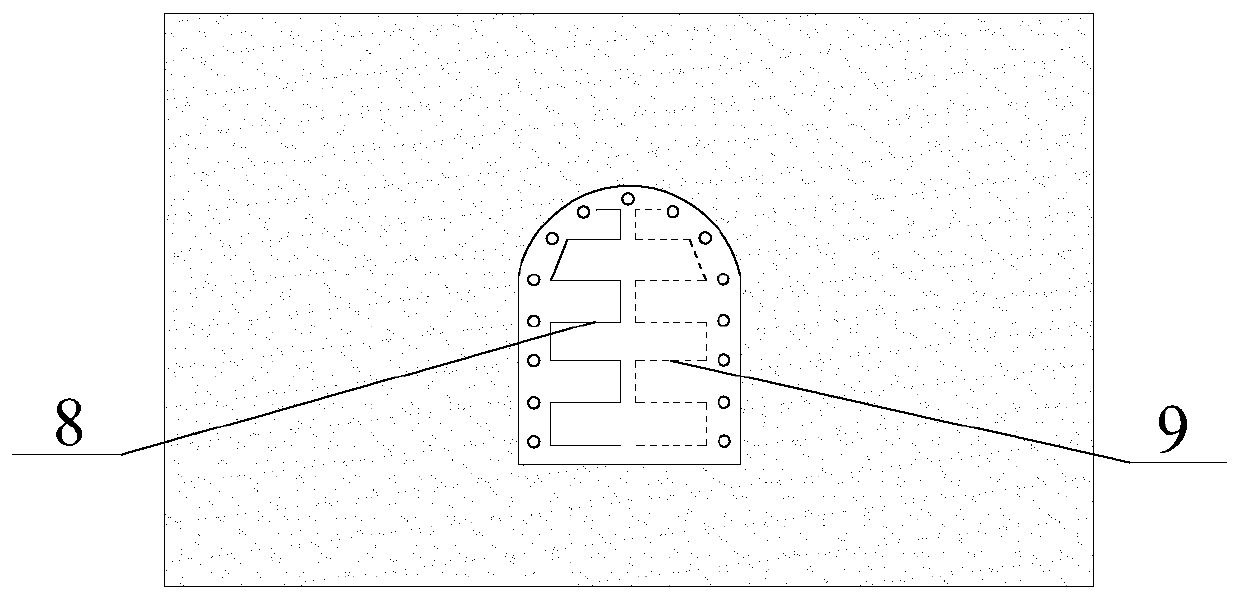

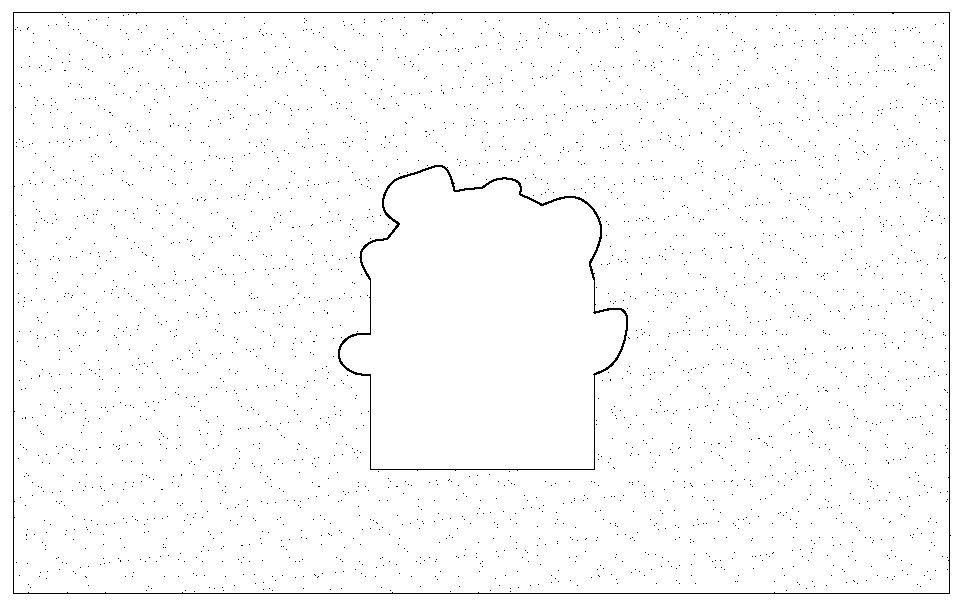

[0026] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0027] A method for forming a smooth surface with preset edge holes in a weakly bonded, multi-fissure water-rich rock roadway of the present invention comprises the following steps:

[0028] (a) Firstly, indent 0.2m inward along the designed outer contour of the working face of the roadway, and mark it with a marker pen, and draw the outer contour of the roadway after indentation;

[0029] (b) According to the calculation standard of the straight-line distance between two adjacent edge holes of 0.5-0.7m, draw an X at each point on the outer contour line of the roadway after indentation as the next step to mark the edge hole;

[0030] (c) Use a drilling rig to drill holes at each edge hole mark from left to right and bottom to top. It is required that the hole deflection rate shall not exceed 10%. Drill the left edge hole 2, right edge hole 3, and left arch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com