Method for detecting thermal imaging defects of high pressure vessel on basis of variable step size segmentation of lines

A high-pressure container and defect detection technology, applied in the field of defect detection, can solve problems such as long cycle, poor safety, and low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

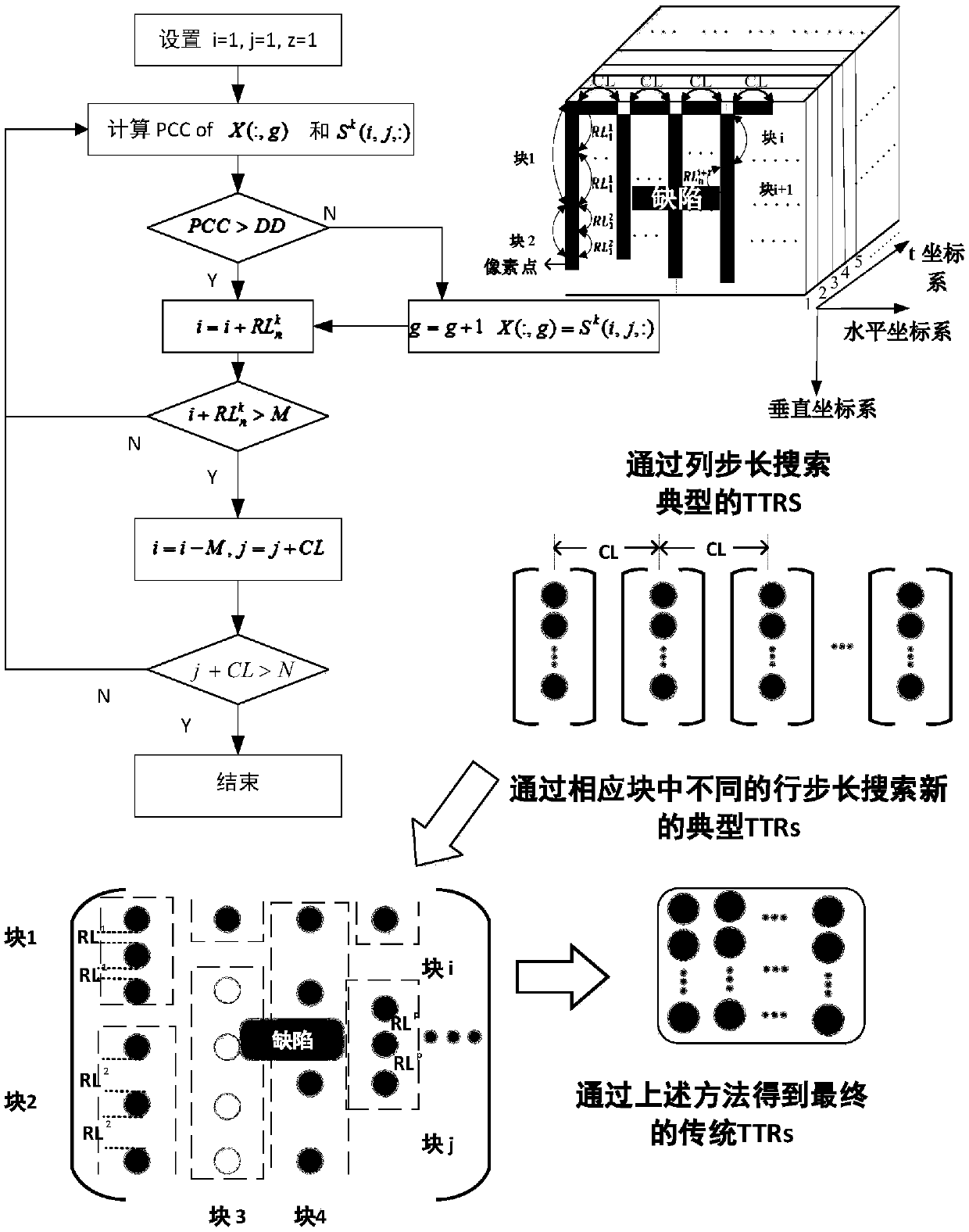

[0072] figure 1 It is a flow chart of the high-pressure container thermal imaging defect detection method based on line-variable step-length segmentation in the present invention.

[0073] In this example, if figure 1 Shown, a kind of PCC-based eddy current pulse thermal image defect feature extraction method of the present invention comprises the following steps:

[0074] S1. The eddy current pulse thermal image is represented by a three-dimensional matrix S, wherein S(i, j,:) represents the i-th row and the j-th column of the three-dimensional matrix S, and the third dimension represents time;

[0075] S2, in order to find the length of the region with the largest temperature difference on the horizontal axis, select the point S(I) with the largest pixel value from the three-dimensional matrix S zz ,J zz , T zz ), among them, I zz 、J zz and T zz Respectively represent the row corresponding value, column corresponding value and time corresponding value of the maximum p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com