Large phase modifier stator end integrated series water internal cooling circulation system and ventilation structure

A stator end and circulation system technology, applied in cooling/ventilation devices, electromechanical devices, casings/covers/supports, etc., can solve the thermal deformation of end structural parts and vibration of the unit, affecting the service life of the camera, It can improve the reliability of water supply, avoid the concentration of magnetic leakage at the end, and increase the capacity of a single machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

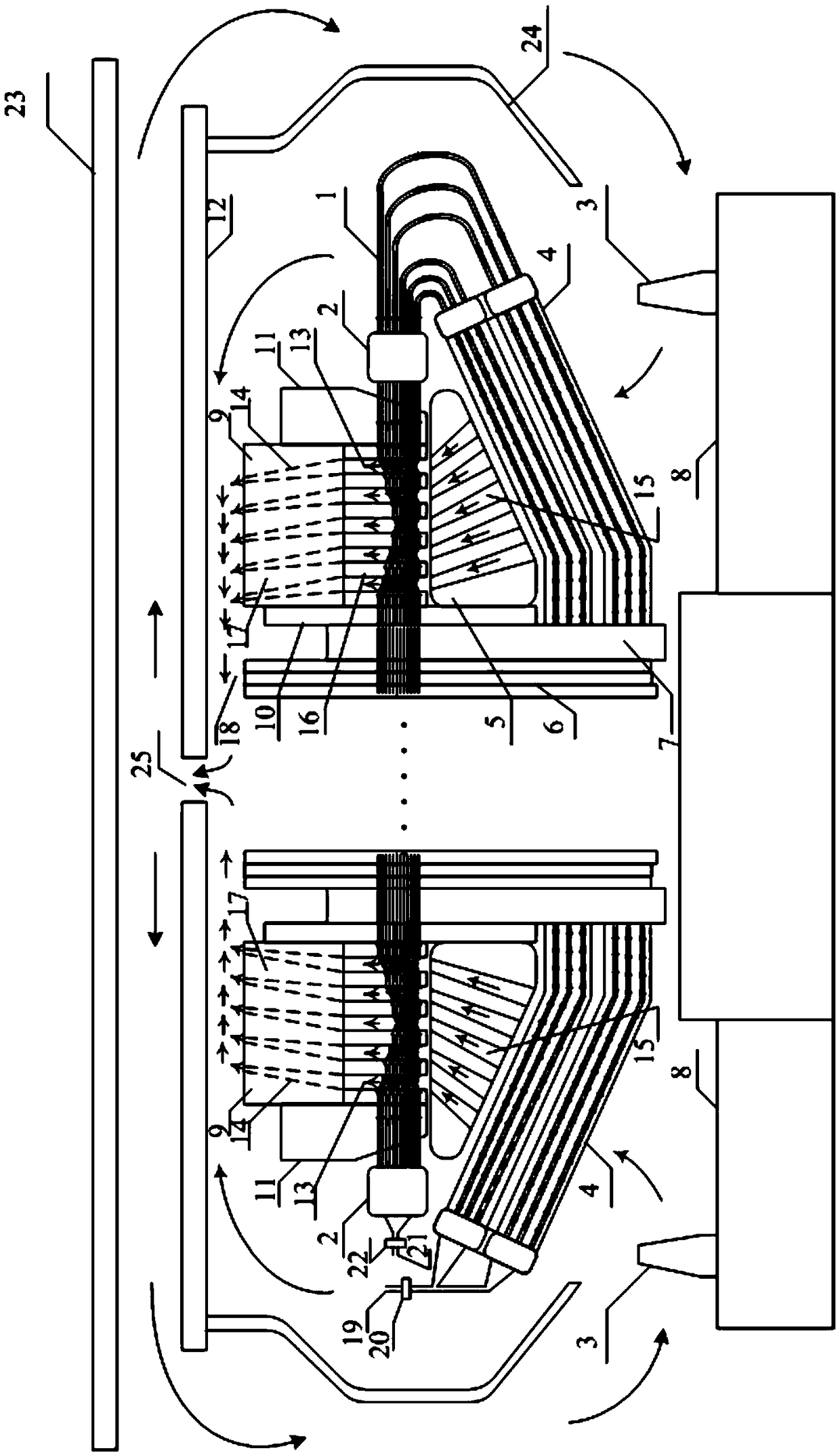

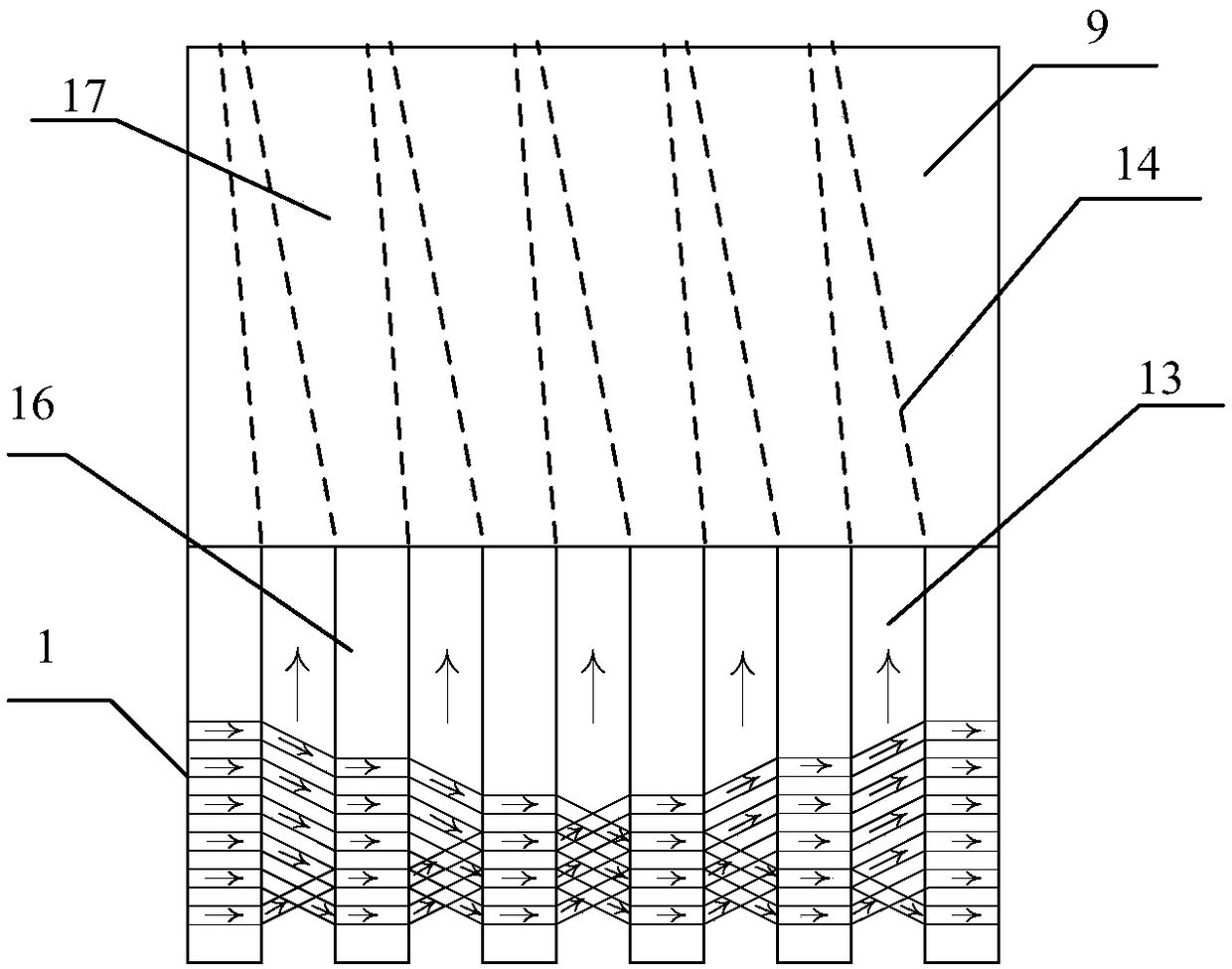

[0028] Example: see figure 1 and figure 2 The stator end of the large-scale condenser in this embodiment is integrated in series with the water internal cooling circulation system and the ventilation structure, including the stator winding 4, the end iron core 6, the tooth pressure plate 7, the rotating shaft 8, the magnetic shield 9, the inner pressure ring 10, The outer pressure ring 11, the machine base and the outer casing 23; the two sides of the end iron core 6 are pressed by the tooth pressure plate 7, the inner pressure ring 10 is pressed on the tooth pressure plate 7, and the tooth pressure plate 7 is provided with a magnetic shield 9, The outer side of the magnetic shield 9 is pressed by the outer pressure ring 11; the end iron core 6 is provided with a two-stage frame to the outside, the frame is provided with an outer casing 23 outside the circumference, and the end iron core 6 is provided with a rotating shaft 8;

[0029] The integrated series water internal coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com