Desulfurizer regeneration method with low energy consumption and desulfurization method

A desulfurization agent and low energy consumption technology, which is applied in the field of desulfurization process, can solve the problems of large steam consumption, influence on technology popularization and application, and high energy consumption, and achieve the effect of reducing raw steam consumption, regeneration cost, and regeneration energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

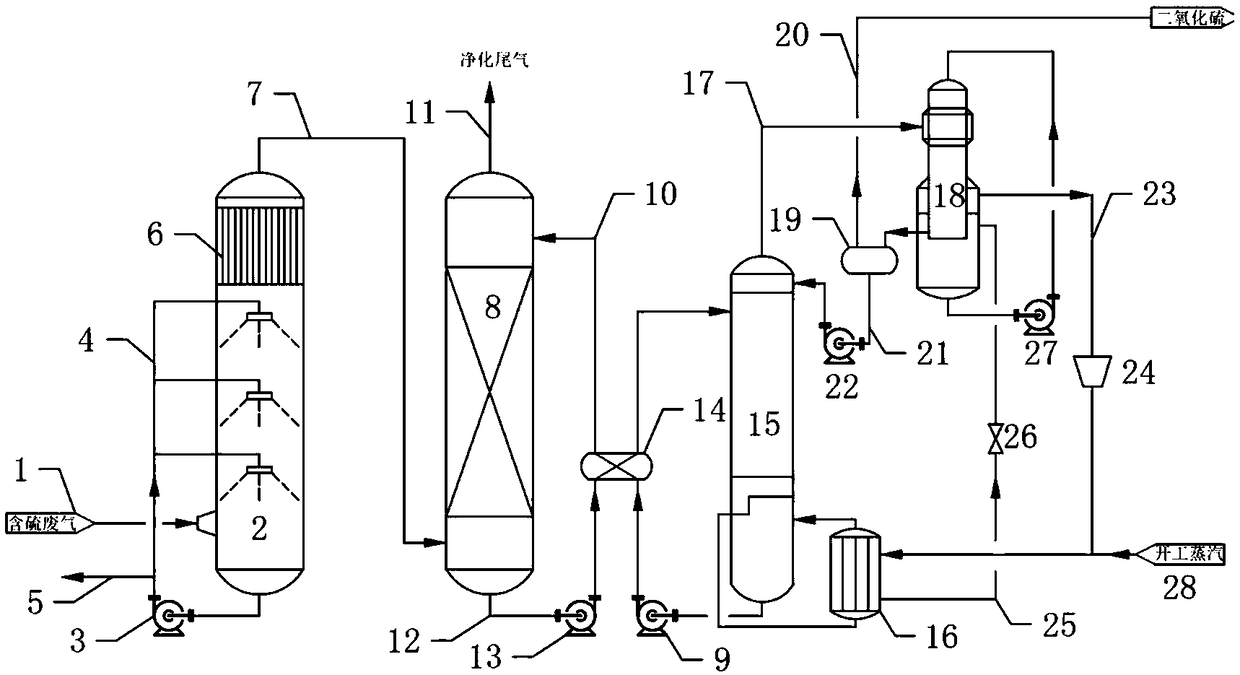

[0040] This embodiment also provides a desulfurization method, please combine figure 1 , which includes the following steps:

[0041] (1) The high-temperature SO2-containing exhaust gas 1 is in contact with the circulating washing water 3 in the cooling scrubber 2 for cooling, dust removal, and removal of particulate matter and sulfur trioxide and other strong acid gases in the exhaust gas. The cooling and washing tower 2 is an empty tower, and the circulating washing water can also be extracted as the effluent circulating slurry 5, and a wet electrostatic demister 6 is installed on the top of the tower to further remove the mist carried by the quenched exhaust gas.

[0042](2) The quenched and dedusted flue gas 7 after cooling and dedusting enters from the bottom of the absorption tower 8 and contacts with the desulfurizer poor liquid 10 in reverse, the sulfur dioxide in the flue gas is captured, the absorption tower 8 is a packed tower, and the purified exhaust gas 11 passes...

Embodiment 2-3

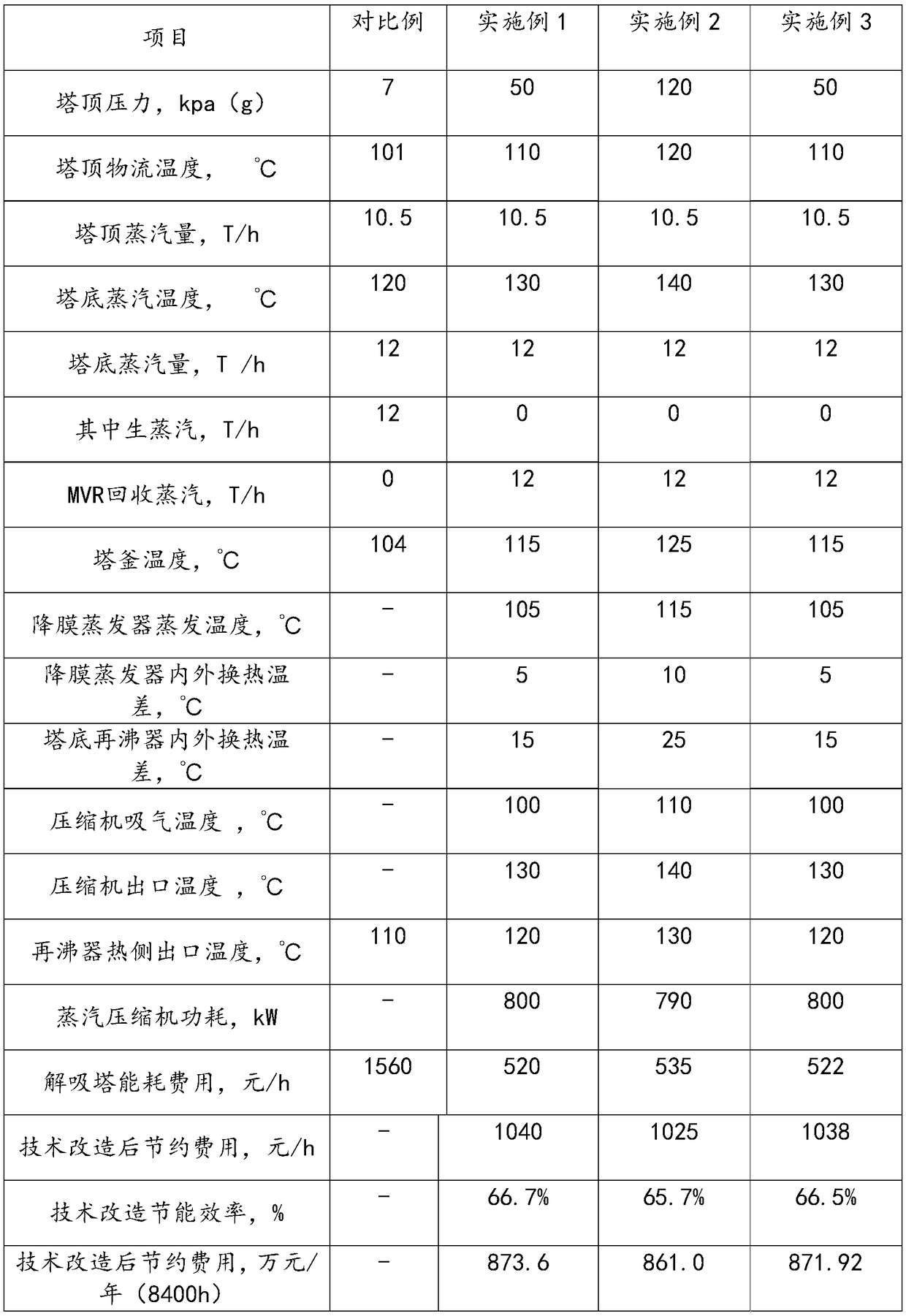

[0047] The same as the process in Example 1, the difference lies in the process parameters of the operation, and in addition the desorption column in Example 3 is a tray column.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com