Membrane treatment method for sulfate process titanium dioxide waste acid

A technology of titanium dioxide waste acid and sulfuric acid method, applied in sulfur trioxide/sulfuric acid, chemical instruments and methods, sulfur compounds, etc., can solve the problems of few, membrane damage, strong corrosion of iron-containing waste acid, etc. The acid quality is good, the economic benefit is great, and the effect of reducing environmental pollution and environmental protection pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

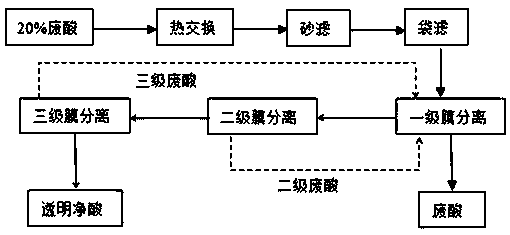

[0024] Such as figure 1 As shown, the raw material is the waste acid obtained by pressure filtration after the sulfuric acid process titanium dioxide solution is hydrolyzed, and the indicators are as follows:

[0025] serial number

project

unit

index

1

temperature

℃

63

2

Sulfuric acid concentration

%

17

3

µs / cm

14750

4

Fe 2+

mg / l

55670

5

Ca 2+

mg / l

2300

6

Mg 2+

mg / l

5230

[0026] Step1. The waste acid is first cooled to 40±2°C through heat exchange;

[0027] Step2. Remove suspended solids through sand filtration and bag filtration to prevent residual metatitanic acid and other impurities from entering the membrane system to block the membrane pores;

[0028] Step3. Then enter the membrane separation system for three-stage separation treatment, and finally obtain transparent clean acid and waste acid enriched with metal ion impurities...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com