Method for strengthening recycled concrete coarse aggregate by using CO2

A technology of recycled concrete and recycled coarse aggregate, applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of poor economy, poor strengthening effect, complicated equipment, etc., and achieve low cost and carbonization The equipment and operation steps are simple and effective, and the effect is remarkable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] This embodiment includes the following steps:

[0035] (1) Preparation of recycled concrete aggregate: the waste concrete is firstly crushed manually, then secondary crushed by a jaw crusher, and sieved to obtain recycled coarse aggregate with a particle size of 4.75 mm to 25 mm for later use;

[0036] (2) Pretreatment of recycled coarse aggregate: the prepared concentration of 0.1% nano-SiO 2 Drenching the slurry on the recycled coarse aggregate prepared in step (1), laying it flat and drying it for subsequent use;

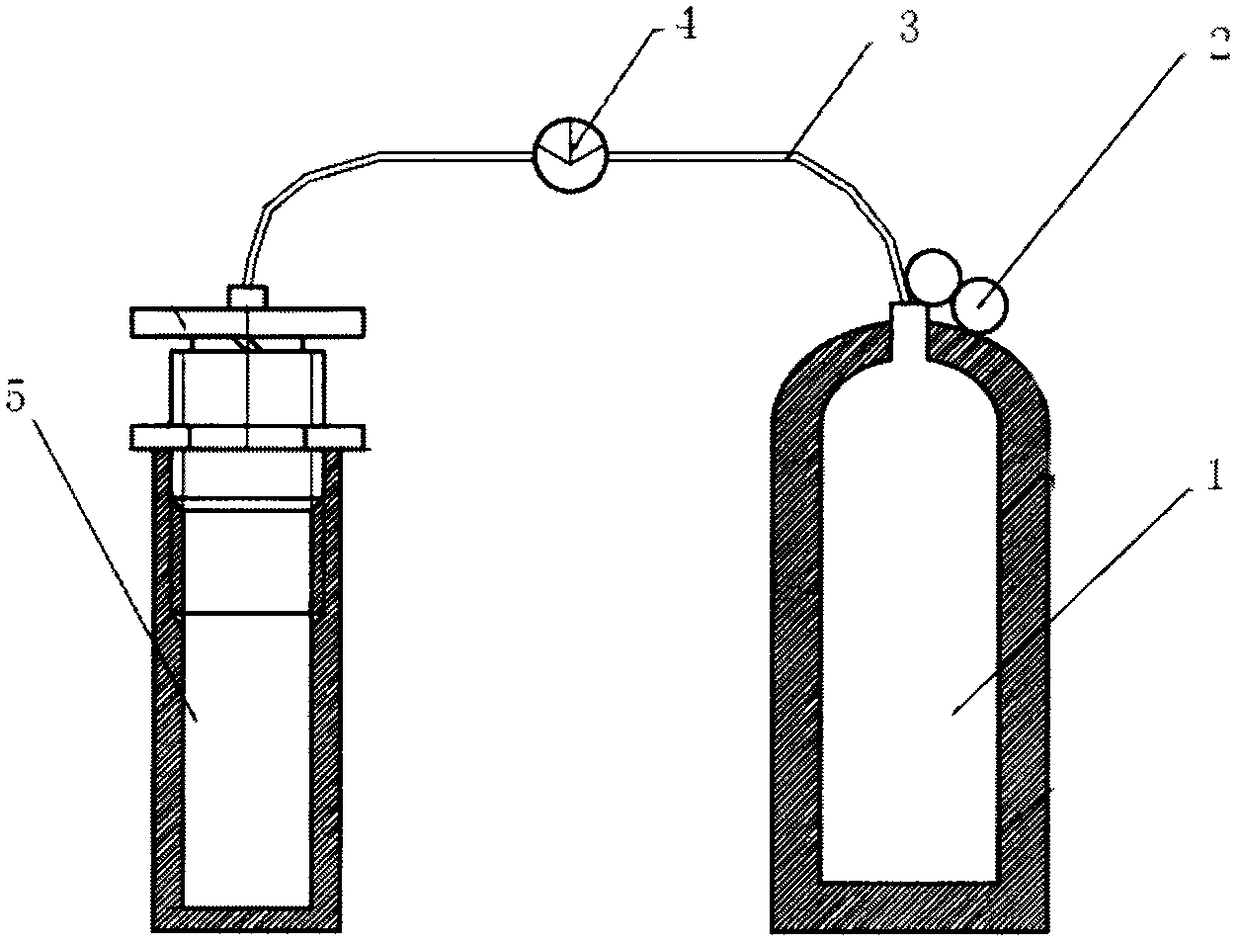

[0037] (3)CO 2 Strengthen the recycled concrete aggregate: put the recycled coarse aggregate prepared in step (2) into the self-made carbonization device, and control the CO by controlling the air pressure regulating valve. 2 The carbonization pressure of the gas is 75KPa, and the carbonization duration is 30 minutes, and the recycled concrete aggregate is strengthened to obtain high-quality recycled concrete aggregate;

[0038] (4) Preparation of recyc...

Embodiment 2

[0040] This embodiment includes the following steps:

[0041] (1) Preparation of recycled concrete aggregate: the waste concrete is firstly crushed manually, then secondary crushed by a jaw crusher, and sieved to obtain recycled coarse aggregate with a particle size of 4.75 mm to 25 mm for later use;

[0042] (2) Regenerated coarse aggregate pretreatment: the prepared concentration is 0.2% nano-SiO 2Drenching the slurry on the recycled coarse aggregate prepared in step (1), laying it flat and drying it for subsequent use;

[0043] (3)CO 2 Strengthen the recycled concrete aggregate: put the recycled coarse aggregate prepared in step (2) into the self-made carbonization device, and control the CO by controlling the air pressure regulating valve. 2 The carbonization pressure of the gas is 75KPa, and the carbonization duration is 90min, and the recycled concrete aggregate is strengthened to obtain high-quality recycled concrete aggregate;

[0044] (4) Preparation of recycled co...

Embodiment 3

[0046] This embodiment includes the following steps:

[0047] (1) Preparation of recycled concrete aggregate: the waste concrete is firstly crushed manually, then secondary crushed by a jaw crusher, and sieved to obtain recycled coarse aggregate with a particle size of 4.75 mm to 25 mm for later use;

[0048] (2) Regenerated coarse aggregate pretreatment: the prepared concentration is 0.3% nano-SiO 2 Drenching the slurry on the recycled coarse aggregate prepared in step (1), laying it flat and drying it for subsequent use;

[0049] (3)CO 2 Strengthen the recycled concrete aggregate: put the recycled coarse aggregate prepared in step (2) into the self-made carbonization device, and control the CO by controlling the air pressure regulating valve. 2 The carbonization pressure of the gas is 150KPa, and the carbonization duration is 30 minutes, and the recycled concrete aggregate is strengthened to obtain high-quality recycled concrete aggregate;

[0050] (4) Preparation of recy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com