Double-position synchronous testing device for rollover valve

A test device and rollover valve technology, which can be used in measurement devices, testing of mechanical components, testing of machine/structural components, etc., can solve the problems of low detection efficiency, long test time, and low data accuracy, and achieve good comparison. effect, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

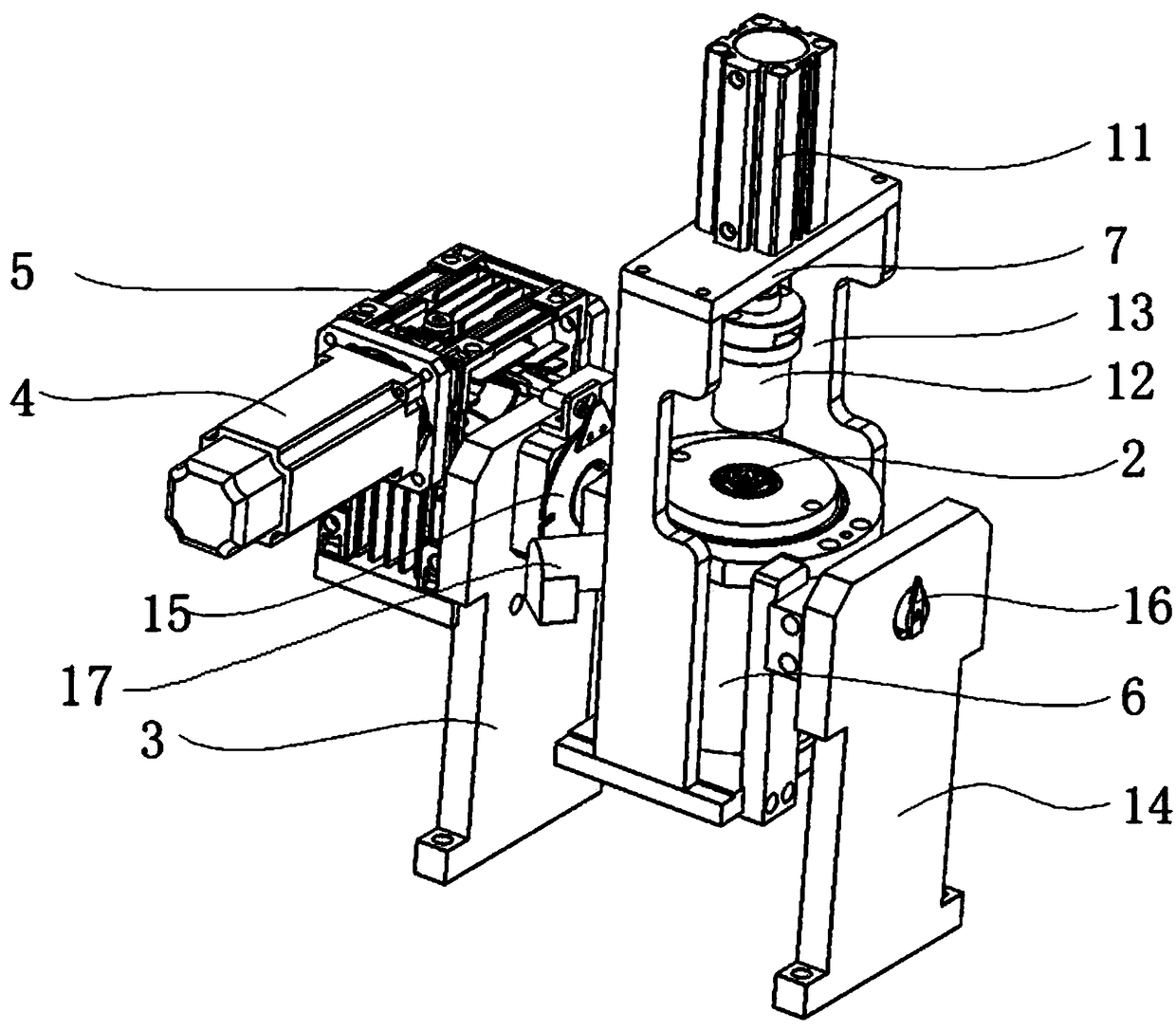

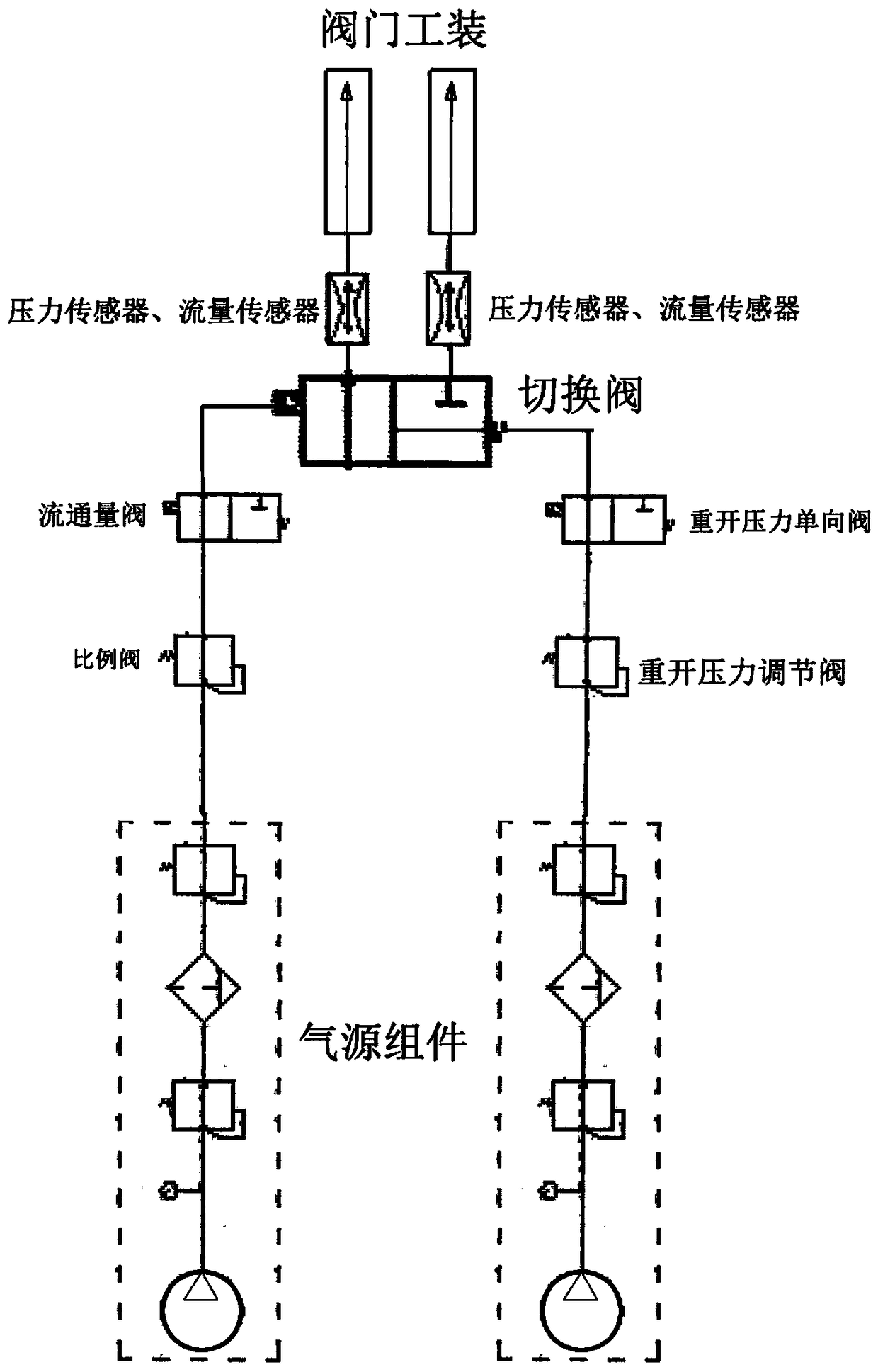

[0026] A kind of synchronous test device for double-station rollover valve in the embodiment of the present invention, such as figure 1 and figure 2 As shown, it includes: mechanical transmission part, pneumatic part, console and dump valve 2. The mechanical transmission part includes workbench 3, servo motor 4, reduction box 5 and valve tooling 6. The servo motor 4 transfers the rotational torque through the reduction box 5 Transfer to the valve tooling 6, the workbench 3 is used to fix and support the servo motor 4, the reduction box 5 and the valve tooling 6, after the reduction box 5 is fixed on the workbench 3, the servo motor 4 and the reduction box 5 are installed in cooperation with each other , so that the rotational movement of the servo motor 4 is transmitted to the rotating shaft between the reduction box 5 and the valve tooling 6 through the reduction box 5, thereby driving the valve tooling 6 to rotate, realizing the simulation of the use state of the tipping va...

Embodiment 2

[0034] Compared with Example 1, the double-station rollover valve 2 synchronous test device in Example 2 also includes a leak tester, specifically, a long air pipe is used to pass through the valve tooling 6 and connect the rollover valve 2 through the leak tester , after the pressure is adjusted, keep the required time for judging whether the test requirements are met. In the actual application process, by comparing the test standards, it can accurately judge whether the tipping valve 2 meets the requirements.

Embodiment 3

[0036] Compared with Embodiment 1, the liquid level measurement part in Embodiment 3 includes a stepping motor and a liquid level detection manipulator, the stepping motor makes the liquid level detection manipulator move up and down, and the liquid level detection manipulator is provided with a photoelectric sensor, through steps The motor pulse positioning and the photoelectric sensor detect the height of the oil level in the valve tooling 6. This design is more accurate and reliable; the performance of the tipper valve 2 can be obtained in more detail by conducting the test of the tipper valve 2 at different oil level heights. The parameter can make the rollover valve 2 have higher safety performance in the application process of the vehicle.

[0037] The photoelectric sensor is also used to send on-off signals, record flow, pressure and height information in real time, and provide an external trigger signal when the console receives an alarm, so as to realize real-time moni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com