Device and method for detecting film missing defects of resin lenses

A defect detection and resin lens technology, which is applied in measuring devices, optical testing of defects/defects, and material analysis through optical means, can solve problems such as insufficient lens cleanliness, lens film leakage, and uneven film thickness distribution, etc., to achieve The effect of improving detection efficiency and automation, improving accuracy, and avoiding recognition errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

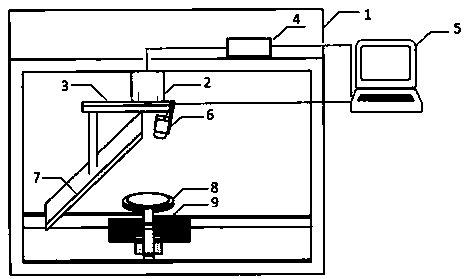

[0026] Such as figure 1 As shown, a resin lens film leakage defect detection device includes a dark box 1, a rotating motor 2, a fixed frame 3, a motion controller 4, a main controller 5, a camera 6, a light source 7, a lens fixed frame 8, and a background plate 9. The rotating motor 2 is fixed on the top of the darkroom 1, and is driven and controlled by the motion controller 4 to execute the rotation command, and its motion parameters are sent by the main controller 4 to the motion controller 4 through serial communication; the fixed frame 3 and the rotating motor 2 are connected through a keyway Connection, its size and structure are determined by the pose relationship between the camera 6 and the light source 7 and the lens; the camera 5 and the light source 7 are relatively installed, wherein the plane of the camera 6 is at an oblique angle to the lens, and its field of view is larger than the diameter of the lens and the pixel The resolution meets the requirement for ide...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com