Linear measurement control method for multi-curved-surface distorted steel tower

A control method and linear measurement technology, which is applied in the field of bridge manufacturing, can solve the problems of multi-curved twisted steel towers that cannot be measured, and achieve the effects of simple measurement, good manufacturing accuracy, and high control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment 1: the linear measurement control method of a kind of multi-curved surface twisted steel tower according to the present invention, the specific steps are as follows:

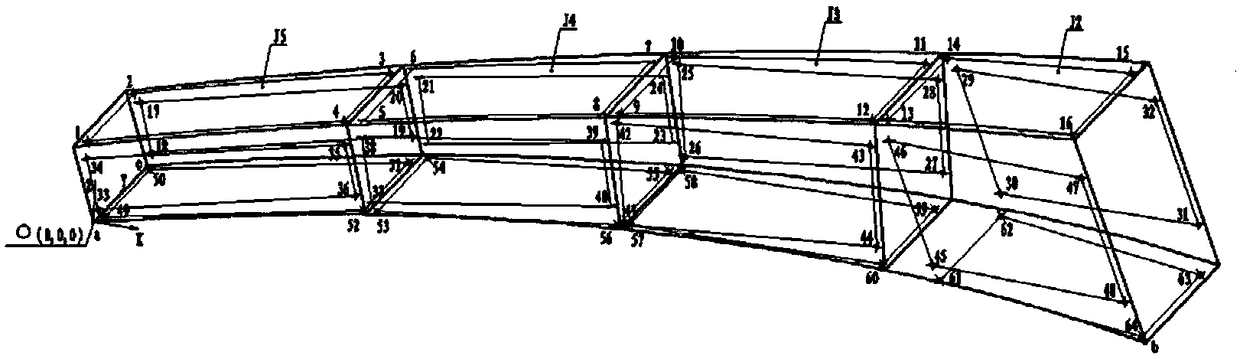

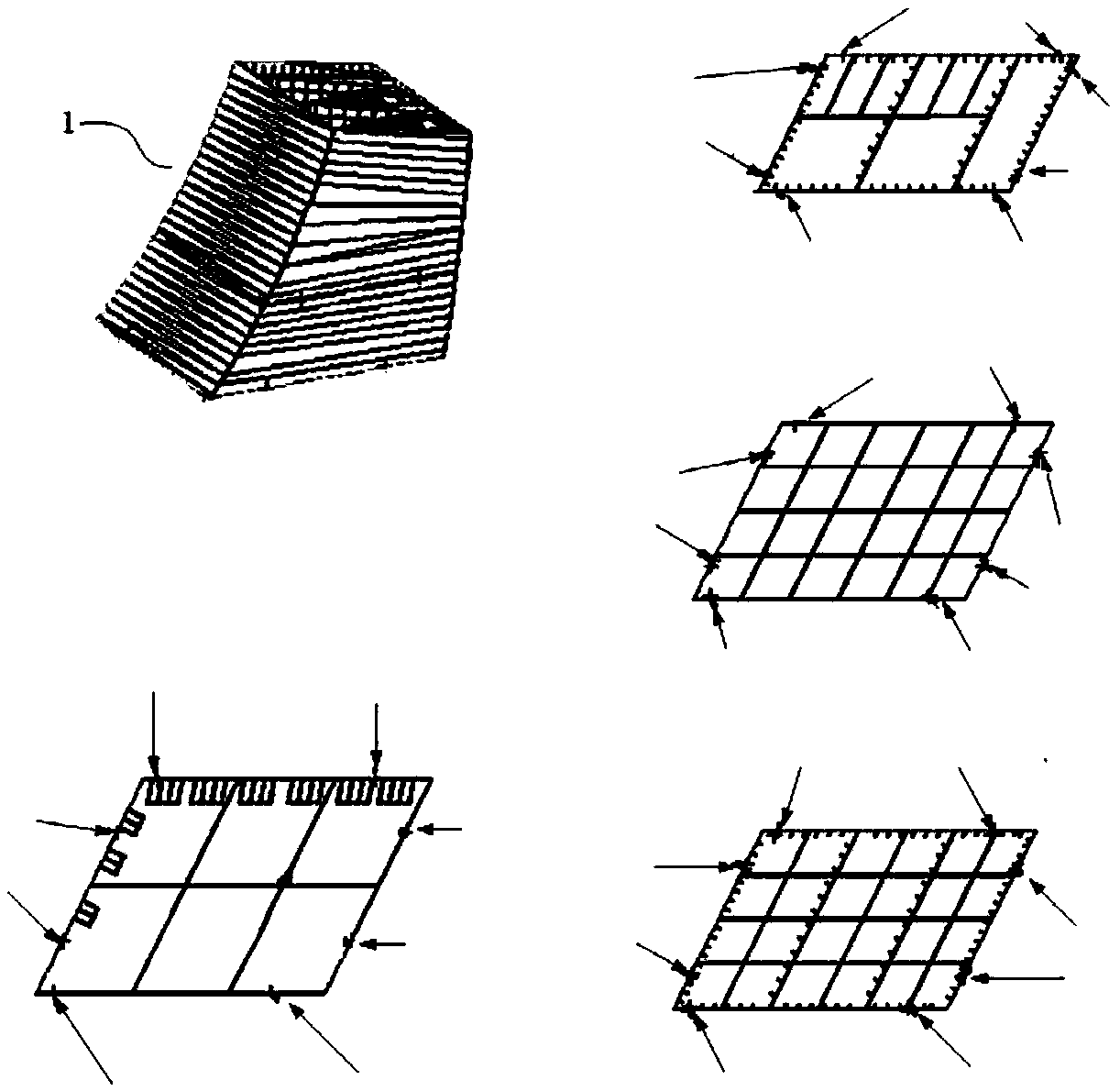

[0017] Such as figure 1 As shown, the three-dimensional model is drawn to obtain the parameters of the steel tower model. Such as Figure 4 As shown, the steel tower segment 1 constituting the steel tower includes a wall plate 101, a side wall plate 102, a diaphragm 103, a web unit 104, and the like. Such as image 3 As shown, according to the structural characteristics of the steel tower segment, select the point at the top of the wall plate of the steel tower segment that is not easily deformed during hoisting and transportation, and can fit the center line of a certain section of the steel tower as the point of the steel tower segment The vertices are used as representative feature points, which are represented by image 3 The direction indicated by the middle arrow and the representativ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com