Ring surface worm gear hob CAD/CAM method based on general CNC milling machine

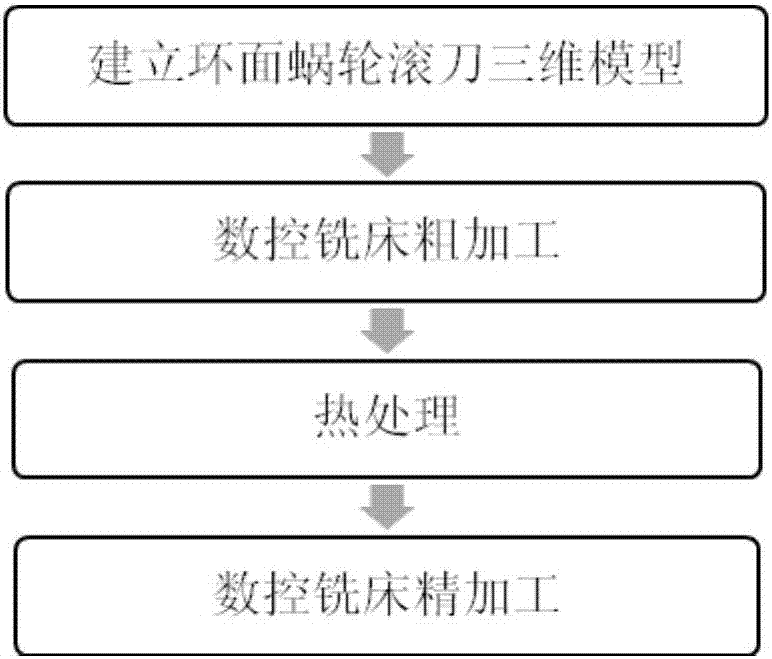

A worm gear hob, CNC milling machine technology, applied in the direction of geometric CAD, milling machine equipment, milling machine equipment details, etc., can solve the problem of no hob manufacturing process, can not use worm gear hobbing, and can not realize the complete design and manufacture of toroidal worm gear hob and other problems, to achieve the best manufacturing accuracy and cutting performance, and simplify the processing technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Examples of the present invention are described below with reference to the accompanying drawings.

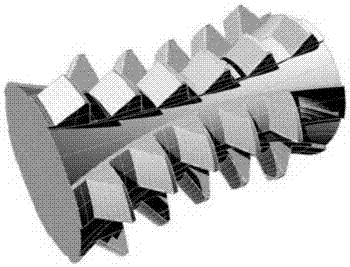

[0015] Taking the planar quadratic enveloping toroidal worm gear hob as an example, the relevant parameters are: the center distance of the toroidal worm pair a = 175mm, the hob tooth root arc radius R f0 =152.4mm, hob addendum arc radius R a0 =158mm, number of rows of cutter teeth N z = 6, the chip flutes are straight grooves, uniformly distributed in the circumferential direction, and the included angle of each rake face is 60°, and the rake face of a row of cutter teeth passes through the tooth thickness point of the hob throat. The hob has a total of 31 teeth, the relief angle of the teeth is χ=5°, and the width of the blade is l E =1mm, knife tooth thickness η=15mm.

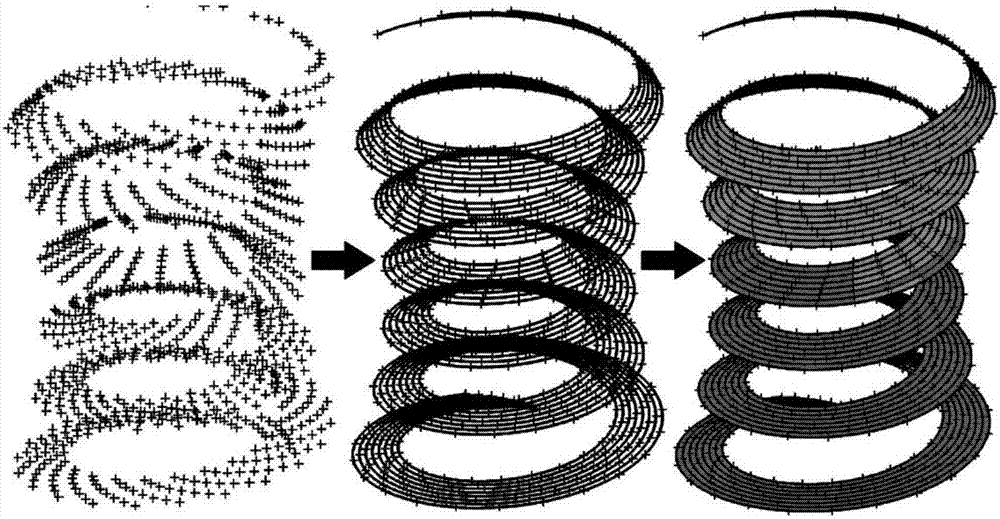

[0016] figure 2 Shown is a schematic diagram of the distribution of point families on the contour surface of the toroidal worm gear hob. Using the helicoid forming principle of the toroidal worm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com