Preparation method of LaFeO3/ZnIn2S4 composite photocatalyst

A znin2s4, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem of incomplete research on the photocatalytic activity of nanocomposite materials, and achieve easy control of preparation conditions and catalytic efficiency. High effect, simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

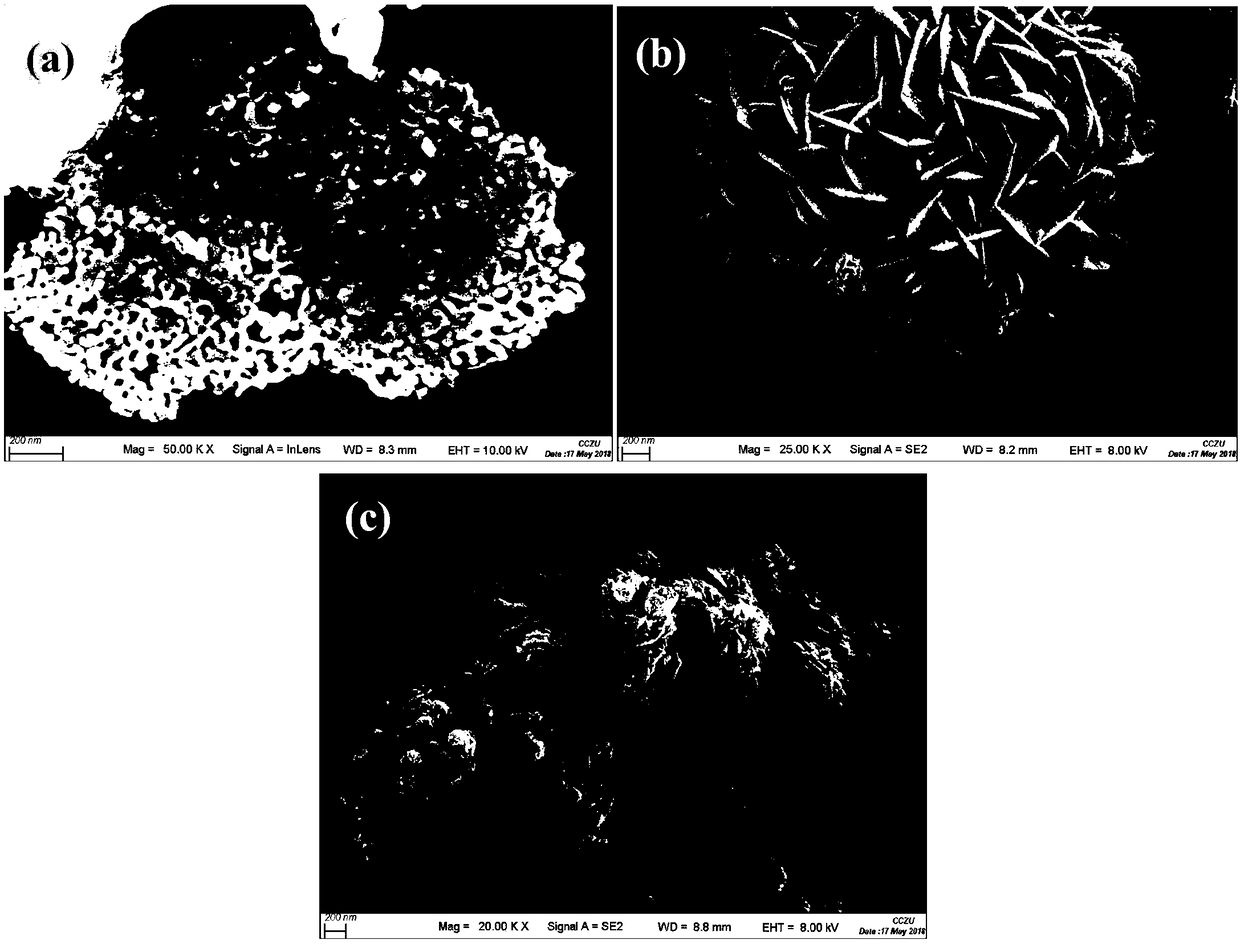

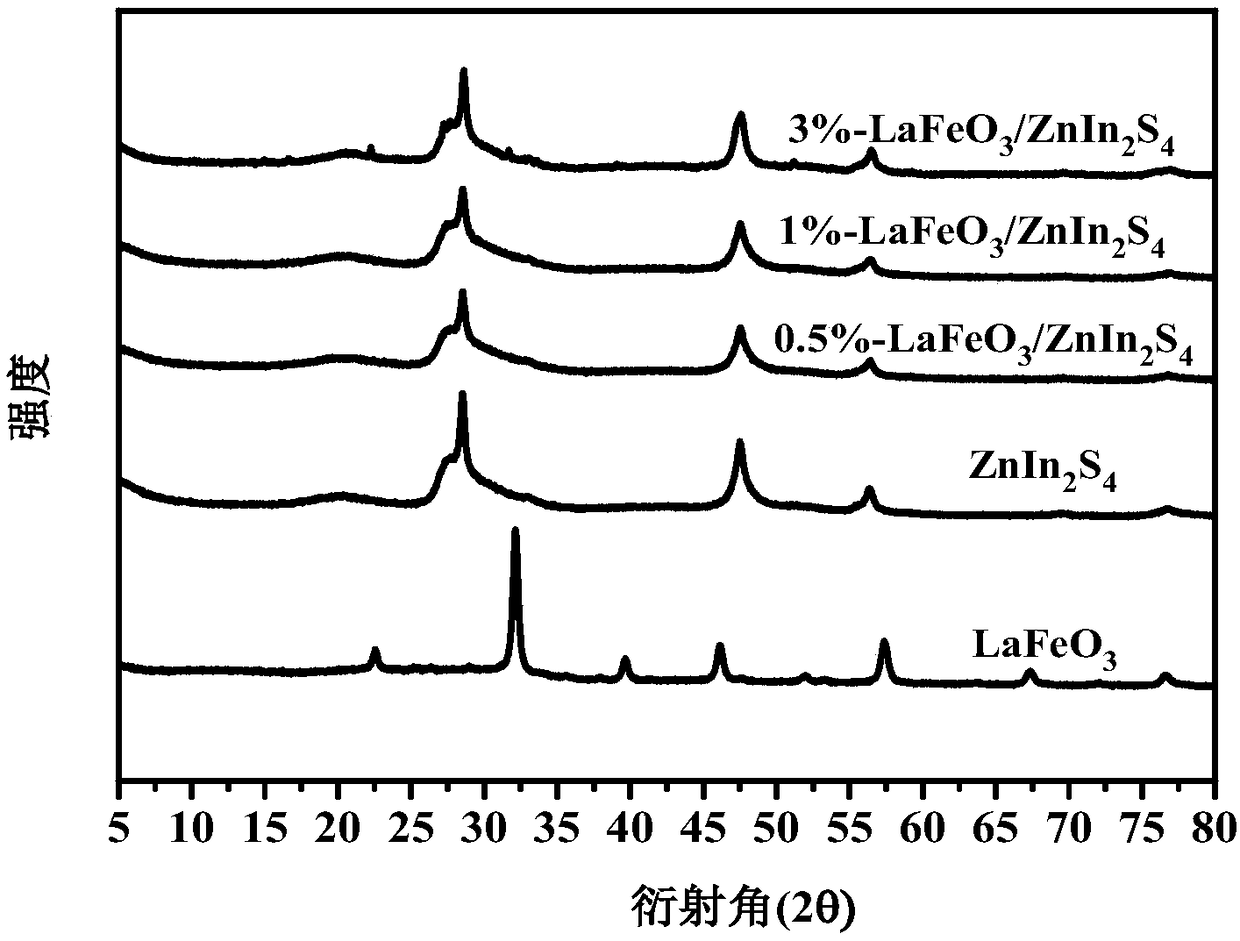

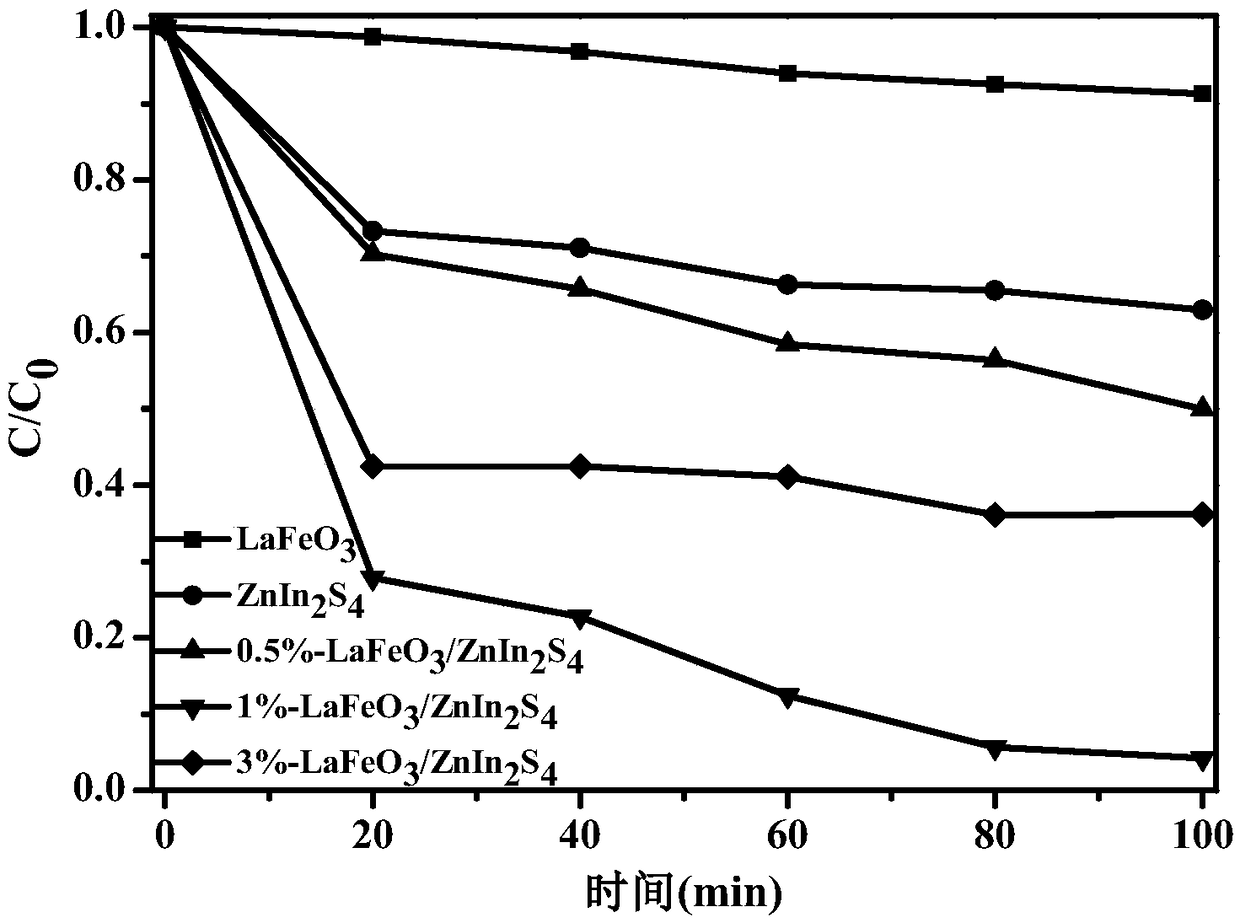

[0023] (1) Preparation of flower spherical indium zinc sulfide ZnIn by hydrothermal method 2 S 4 : Zinc sulfate hydrate ZnSO 4 ·7H 2O (0.3444g, 1.2mmol), zinc nitrate hydrate Zn(NO 3 ) 2 4.5H 2 O (0.3790g, 2.0mmol), thioacetamide (TAA) (0.4508g, 6.0mmol) and cetyltrimethylammonium bromide (CTAB) (0.3g, 0.82mmol) were sequentially added to 70mL of After it was completely dissolved in ionized water by magnetic stirring, it was transferred to a 100mL autoclave and sealed, heated to 160°C, and the reaction time was 12h. After the reaction kettle is cooled to room temperature, centrifuge and alternately wash 3 times with deionized water and absolute ethanol to ensure that CTAB is fully washed, dry at 60°C and grind to obtain a yellow product;

[0024] (2) Preparation of flaky lanthanum ferrite LaFeO by sol-gel method 3 : Ferric nitrate Fe(NO 3 ) 3 (0.4837g, 2.0mmol), lanthanum nitrate La(NO 3 ) 3 (0.65g, 2.0mmol) and citric acid (0.7686g, 4.0mmol) were successively disso...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com