Sand and stone screening device having wastewater treatment function

A technology of sewage treatment and screening device, which is applied in the direction of flocculation/sedimentation water/sewage treatment, solid separation, wet separation, etc., can solve the problems of inability to reasonably plan the sand heap space, limited working length, limited space for building materials, etc. Achieve the effect of improving sewage treatment effect, saving cost and energy, and improving space utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

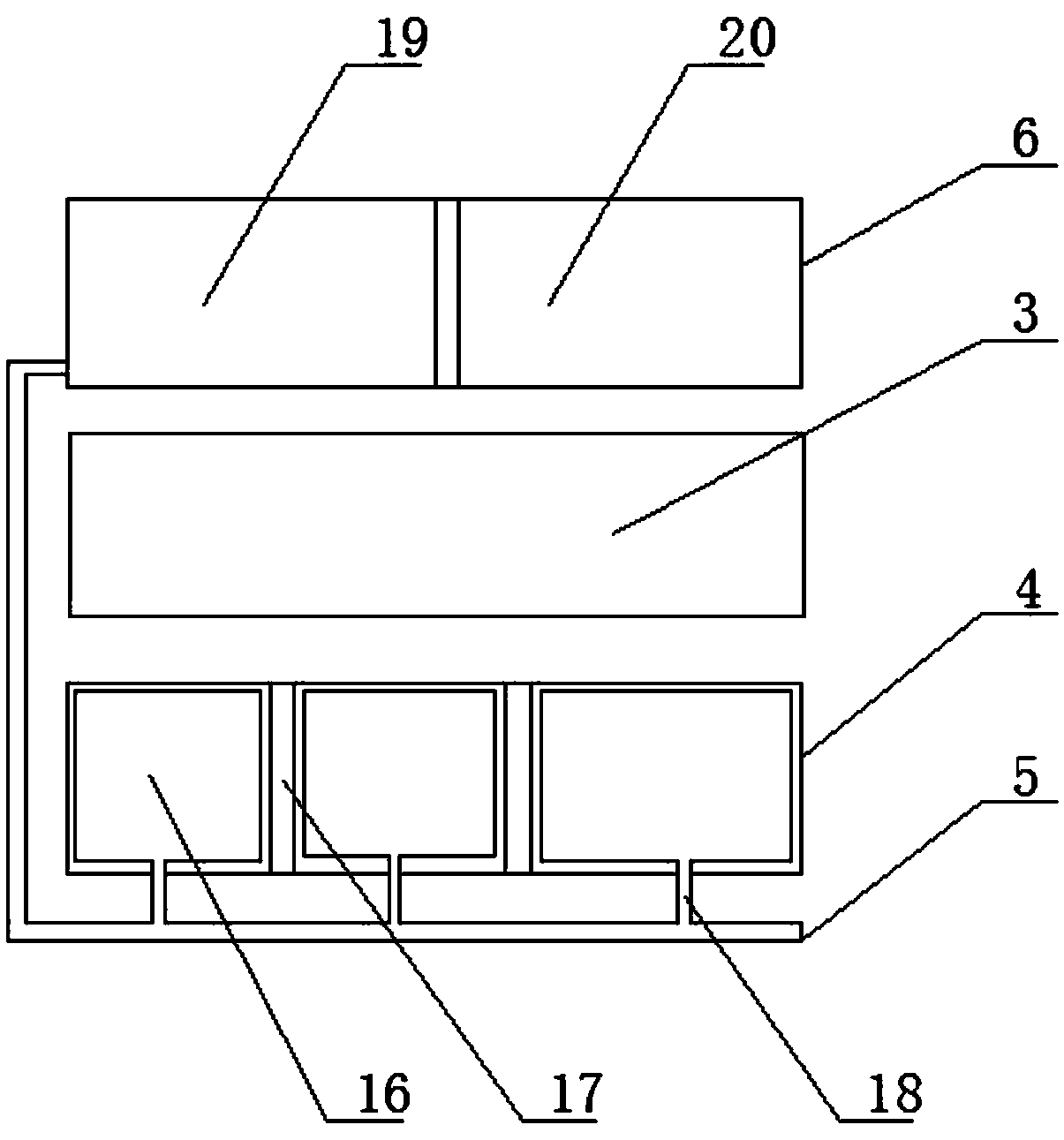

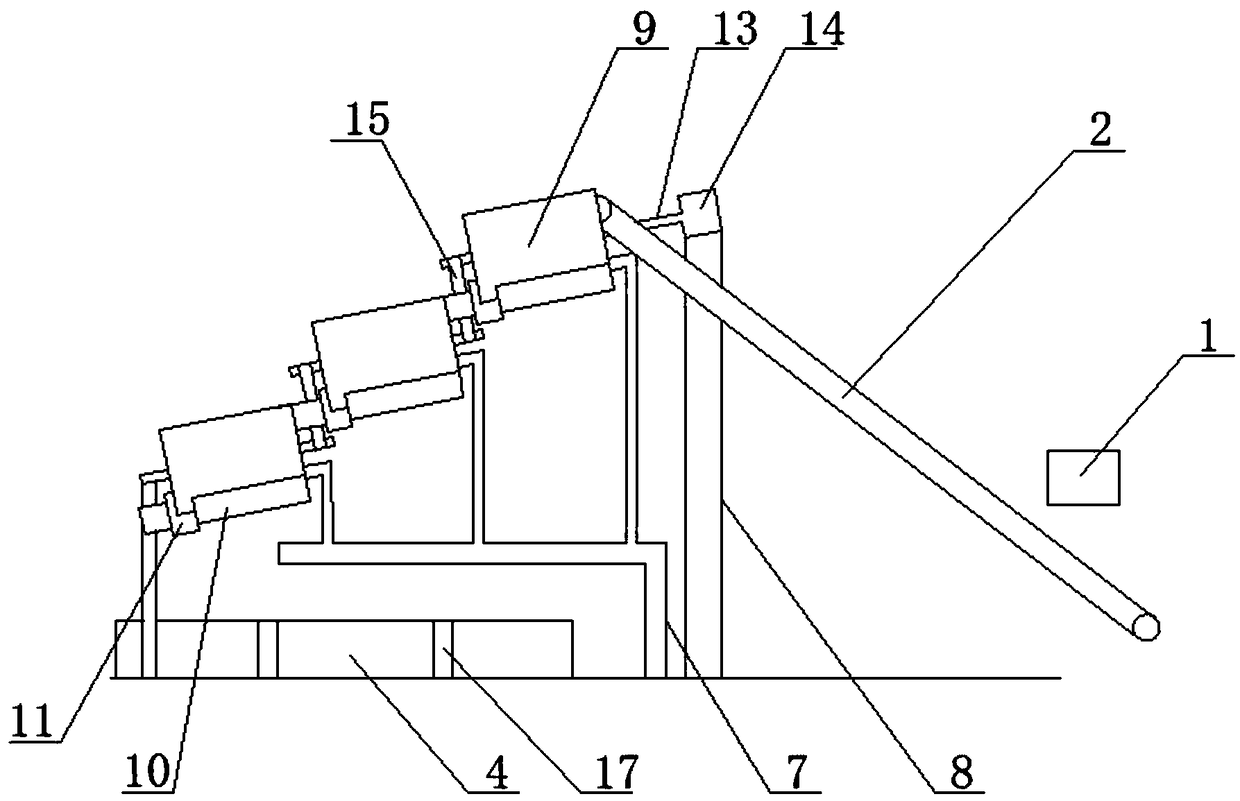

[0036] This embodiment provides a sand and gravel screening device with a sewage treatment function, which includes a sand loading hopper 1, a conveying device 2 for transporting the sand in the sand loading hopper 1 to a high place, a three-stage sand filtering device, and a stacker. Sand room 4, drainage ditch 5, waste water recovery tank 6, sand washing device 7;

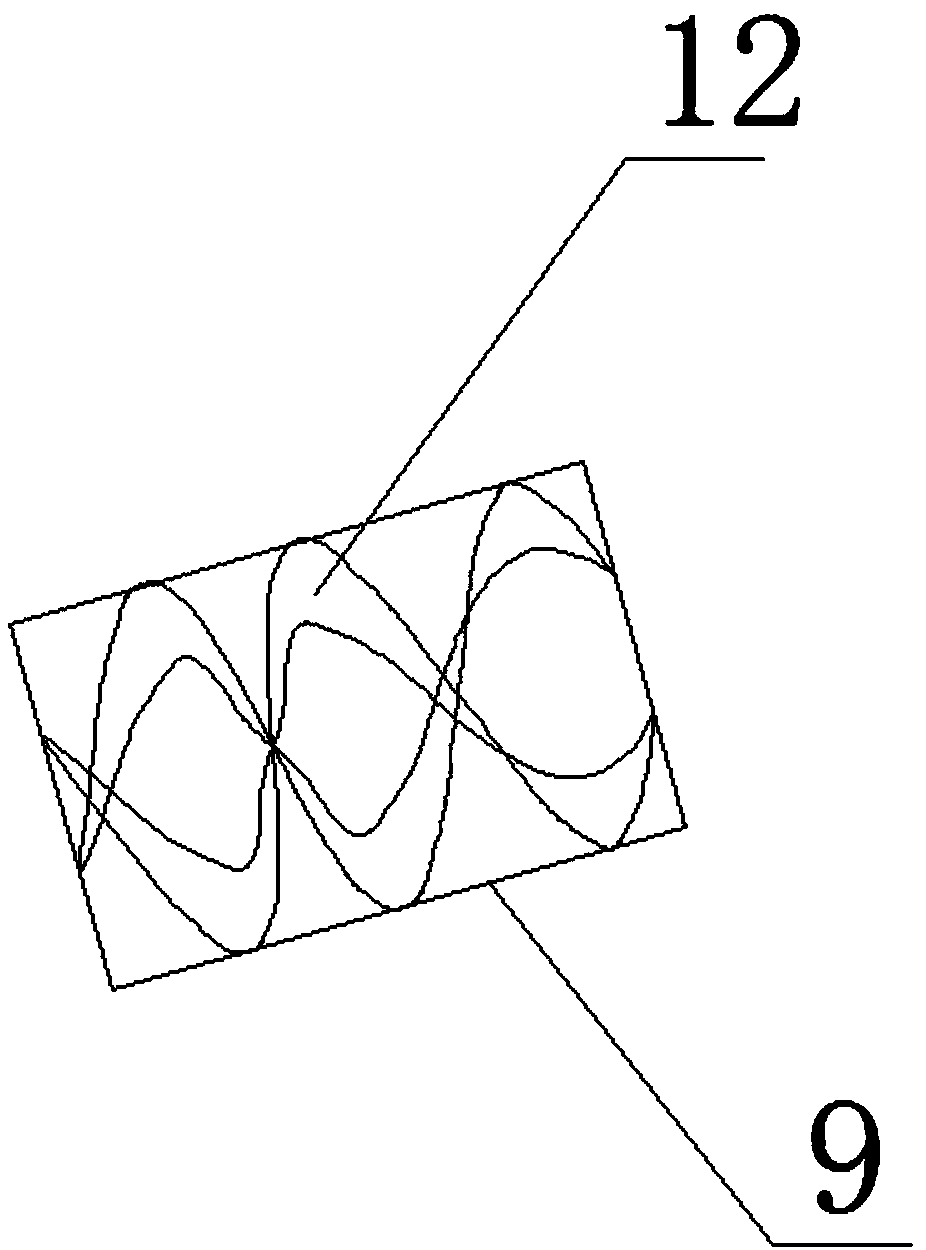

[0037] The tertiary sand filter device includes three steps and a screen washing device inclined downward in the longitudinal direction, and a bracket 8 for fixing the screen washing device; the screen washing device includes a drum with small holes on the outer wall 9. The driving device of the drum 9, located directly below the drum 9 and arranged obliquely downwards, the section is arc-shaped and the lower end extends into the bottom wall 10 of the inlet end of the next screening and washing device, which is set at the outlet end of the drum 9 to block the flow from the drum 9. The baffle plate 11 for sand and...

Embodiment 2

[0045] This embodiment provides a sand and gravel screening device with sewage treatment function. Compared with Embodiment 1, the difference is that the cross-sectional shape of the baffle plate 11 is L-shaped; the small hole on the drum 9 is circular; the sand washing pipeline includes a water storage main pipe connected to the suction pipe, and a spraying branch pipe corresponding to each drum 9 arranged on the water storage main pipe; one end of each spraying branch pipe extends into the drum 9 is parallel to the inside of the drum 9, and the side pipe wall of the spraying branch pipe facing the drum 9 is uniformly provided with nozzles; the waste water recovery pool 6 is connected with an external water supply device; Gravel falls into the protective net in the described gutter 5 .

[0046] The L-shaped baffle plate 11 can effectively prevent the sand and gravel at the outlet end of the drum 9 from falling onto the bottom wall 10 and destroy the screening effect; the sand...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com