Energy-saving in-situ thermal desorption treatment device and energy-saving in-situ thermal desorption treatment method for greasy dirty contaminated soil

A technology of polluted soil and treatment equipment, which is applied in the field of energy-saving in-situ thermal desorption treatment equipment, which can solve the problems of secondary pollution, increased construction costs, and large hardened area of equipment, and achieves easy operation, simple device composition, and low operating costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

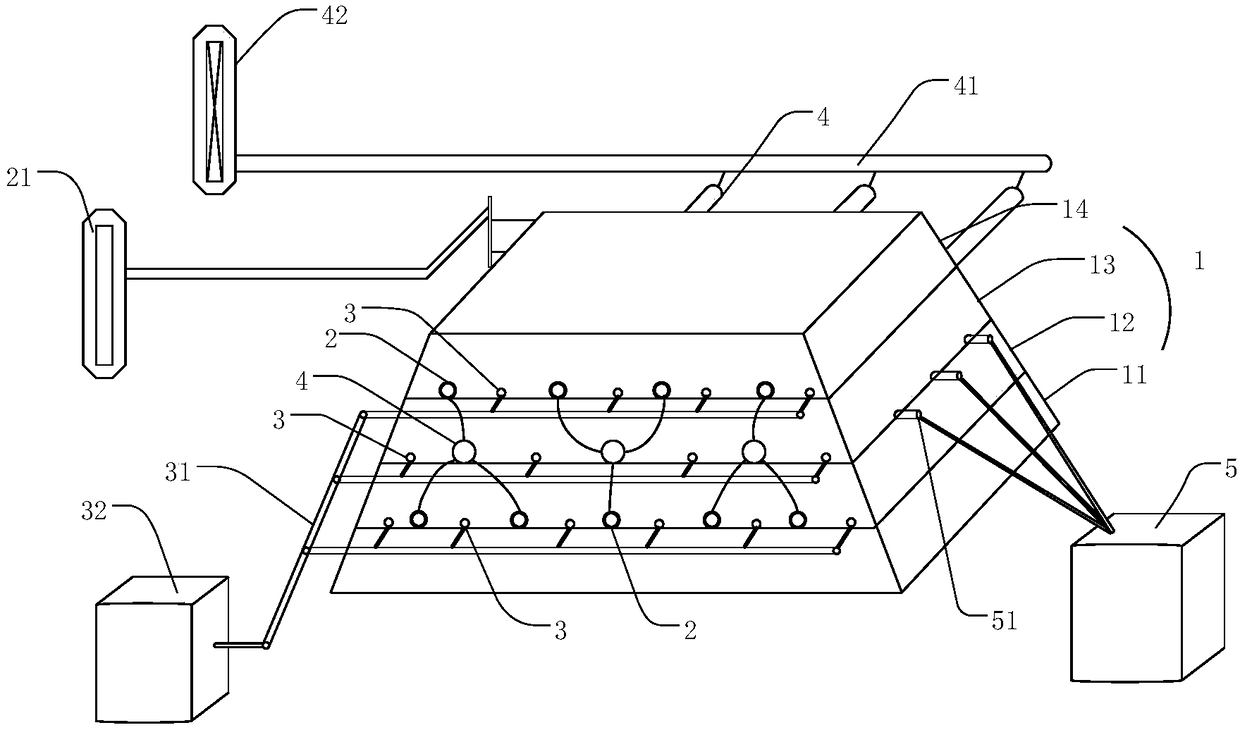

[0058] The schematic diagram of the composition and structure of the energy-saving in-situ thermal desorption treatment device disclosed in Example 1 is as follows figure 1 In the examples described, the structures in the figures are not drawn strictly to scale in order to highlight the characteristics of different parts and assemblies.

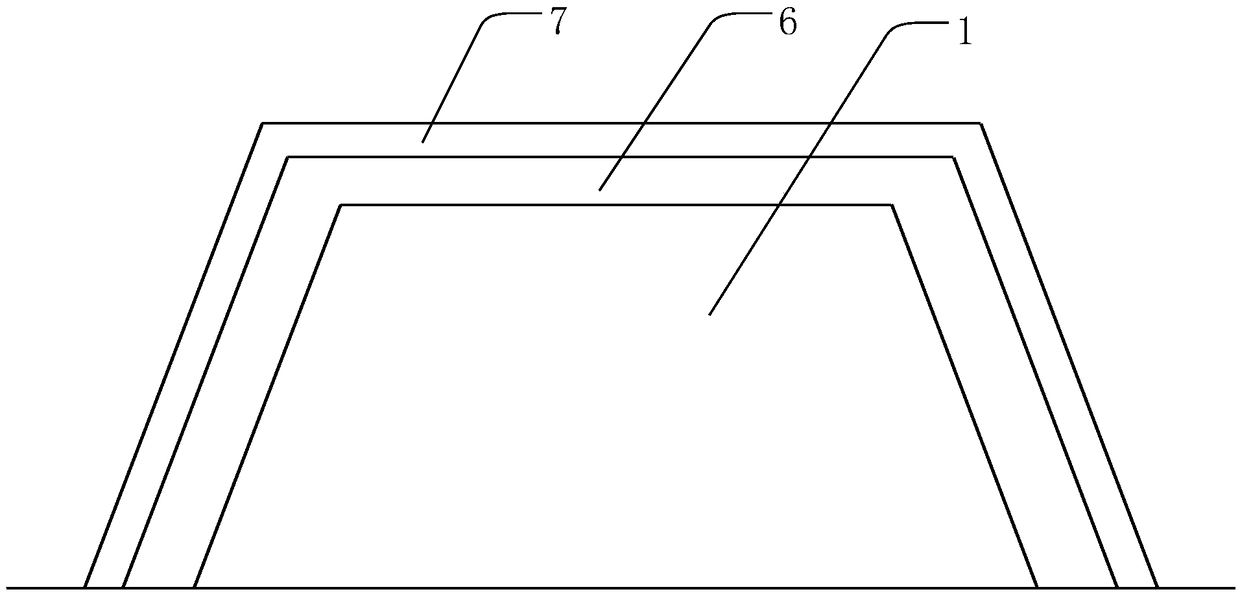

[0059] Contaminated soil after excavation is built into a quadrangular platform-shaped soil mound 1 in situ. The soil mound 1 includes four layers of contaminated soil, laid in sequence from bottom to top, and the height of each layer of contaminated soil is between 0.6 and 1m; After laying the first layer of polluted soil 11 on the bottom layer, install the heating pipe 2 and the extraction pipe 3. There are multiple heating pipes 2 and multiple extraction pipes 3. The distance between the lifting tube 3 and the heating tube 2 is set between 30 and 50 cm; the extraction tube 3 is cut and processed; a temperature sensor (not shown in the figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com