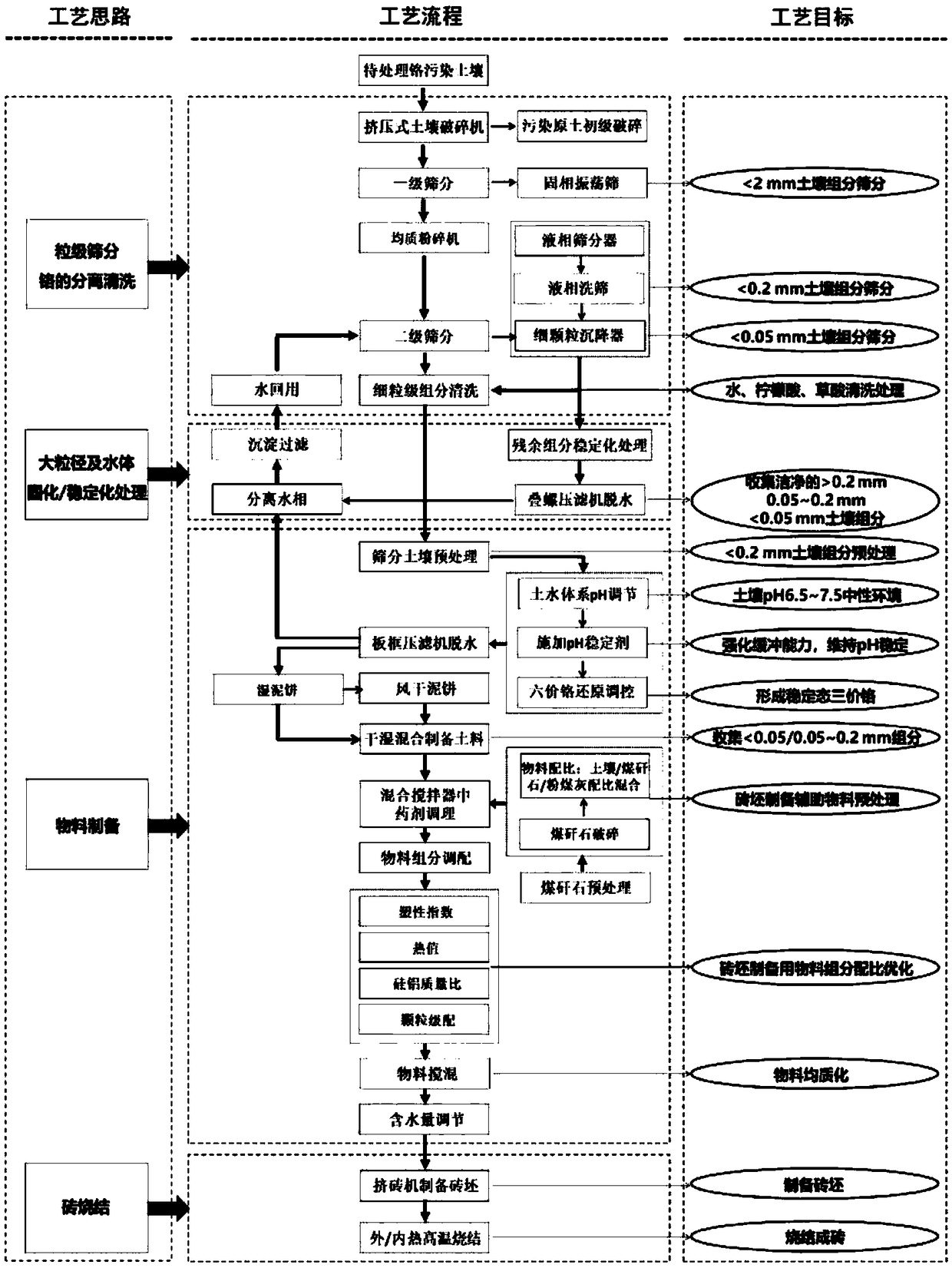

Harmless and recycling remediation method for chromium-contaminated soil

A technology of chromium-contaminated soil and a remediation method, applied in the field of harmless and resource-based remediation of chromium-contaminated soil, can solve problems such as secondary pollution of hexavalent chromium Cr, improve the strength and hardness of the rotating body, enhance the solid-sealing effect, The effect of improving repair efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Example 1 Sintered brick technology remediation of chromium-contaminated soil in chemical industry

[0047] The polluted soil used in this example is collected from a chemical plant that has been polluted by heavy metal chromium for a long time, and the average total chromium concentration is 27000mg kg -1 , in which the average concentration of hexavalent chromium (Cr(VI)) reaches 5000mg·kg -1 . It can be seen through small test experiments that after the screening, reduction and material preparation described below, the hexavalent chromium (Cr(VI)) content of the mixed material is 120mg / Kg (using "solid waste-leaching toxicity leaching method acetate buffer solution "(HJ / T 300-2007) method), the content does not meet the sintering requirements, so after adjustment, a series of process methods of sieving, cleaning, reducing, material allocation and brick high-temperature sintering of fine-grained components of chromium-contaminated soil are used in sequence. Complete...

Embodiment 2

[0092] Example 2 Technical restoration of sintered bricks for a certain chromium-contaminated industrial site soil

[0093] The polluted soil used in this example is taken from a site polluted by heavy metal chromium for a long time, and the average total chromium concentration is 22500mg kg -1 , in which the average concentration of hexavalent chromium (Cr(VI)) reaches 4200mg·kg -1 . Through the small test experiment, it can be seen that after the screening, reduction and material preparation described below, the hexavalent chromium (Cr(VI)) content of the mixed material is 65mg / Kg (using "solid waste-leaching toxicity leaching method acetate buffer solution "(HJ / T 300-2007) method), the content does not meet the sintering requirements, so after adjustment, a series of process methods of sieving, cleaning, reducing, material allocation and brick high-temperature sintering of fine-grained components of chromium-contaminated soil are used in sequence. Complete the remediation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com