High-linear-speed self-sharpening CBN grinding wheel for processing unquenched alloy steel parts and preparation method thereof

An alloy steel, unquenched technology, applied in the field of high linear speed self-sharpening CBN grinding wheel and its preparation, can solve the problems of low grinding wheel hardness, low life and low grinding wheel efficiency, and achieve stable processing, long life and long dressing interval. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

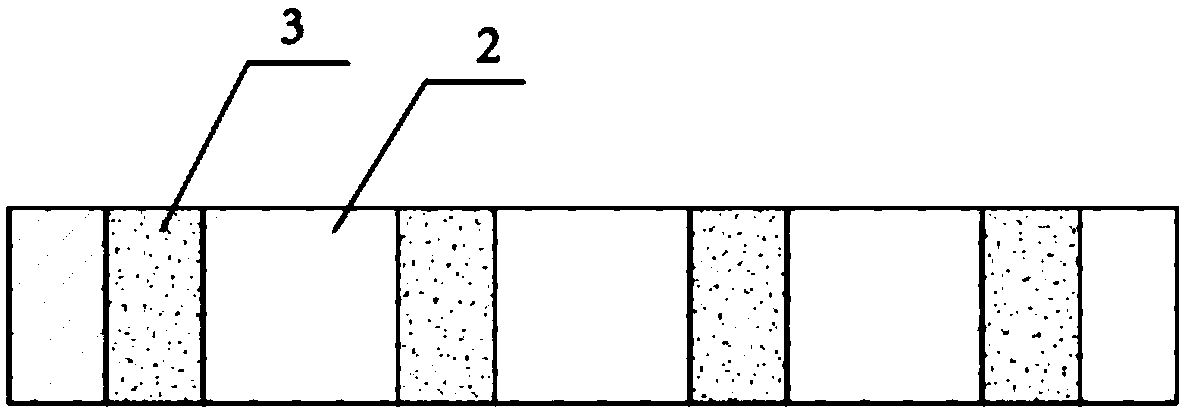

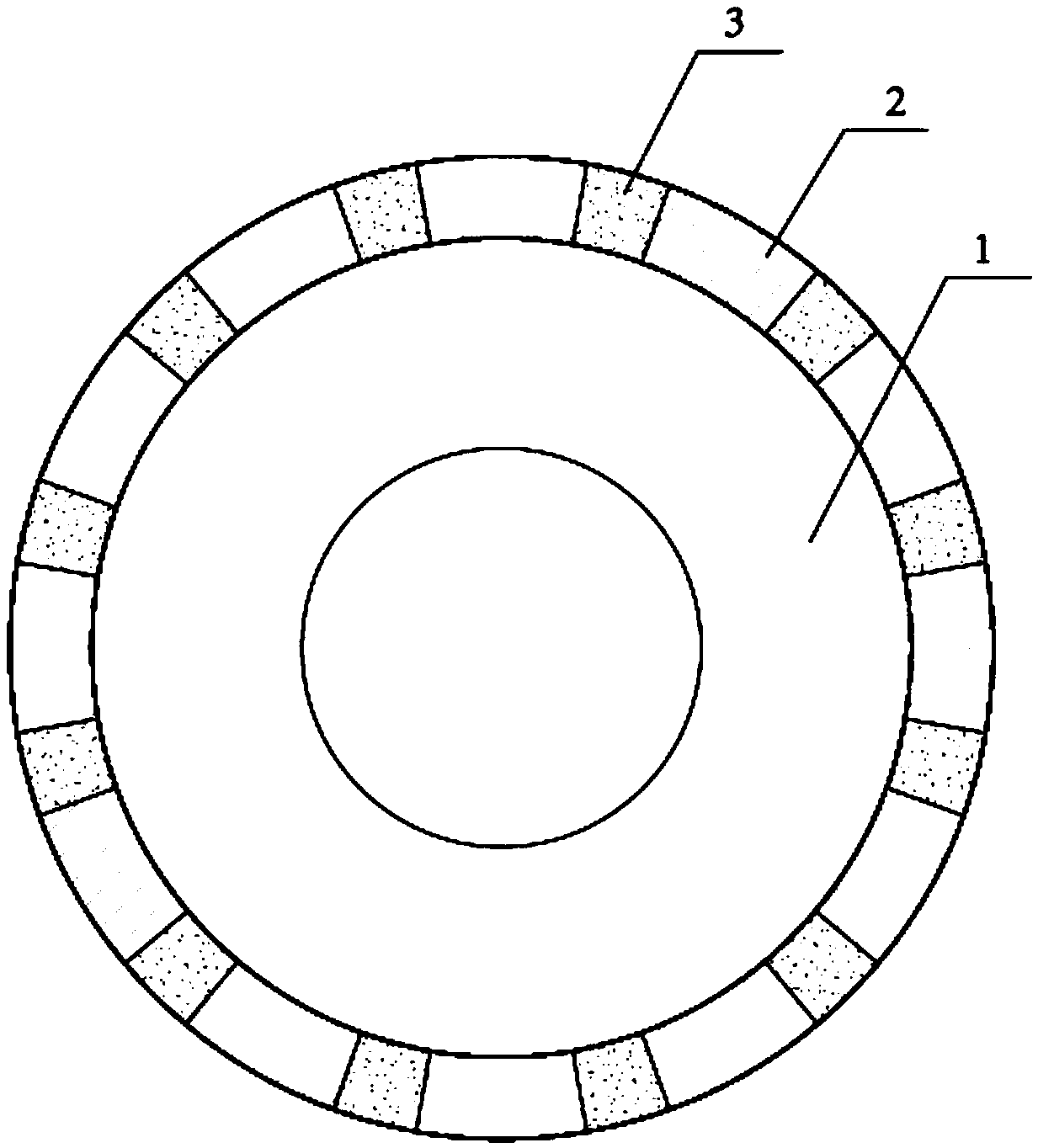

[0035] Such as figure 1 , figure 2 As shown, a high-speed self-sharpening CBN grinding wheel for processing unquenched alloy steel workpieces includes a steel substrate 1, an abrasive block 2 bonded to the steel substrate and an auxiliary grinding self-sharpening block 3, wherein the abrasive block and the auxiliary The grinding self-sharpening blocks are distributed at intervals. Abrasive agglomerate length is 38.7mm, forming density is 2.32, auxiliary grinding self-sharpening agglomerate length is 16.7mm, forming density is 2.48; if abrasive agglomerate and auxiliary grinding self-sharpening agglomerate have the same length, the performance will be worse, processing After 1300 pieces, sticky chips appeared.

[0036] The raw material composition and weight percentage of the abrasive block are: 80 / 100 grain size CBN abrasive 57%, vitrified bond 36%, phenolic resin liquid 7%; the auxiliary grinding self-sharpening block raw material composition and weight percentage are: 80 / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com