Anilox roller cleaning method

A technology of anilox roller and pulse laser, which is applied in the direction of printing, printing machines, general parts of printing machinery, etc., can solve the problems of inability to clean, ablation, etc., and achieve the effect of thorough cleaning and fast cleaning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

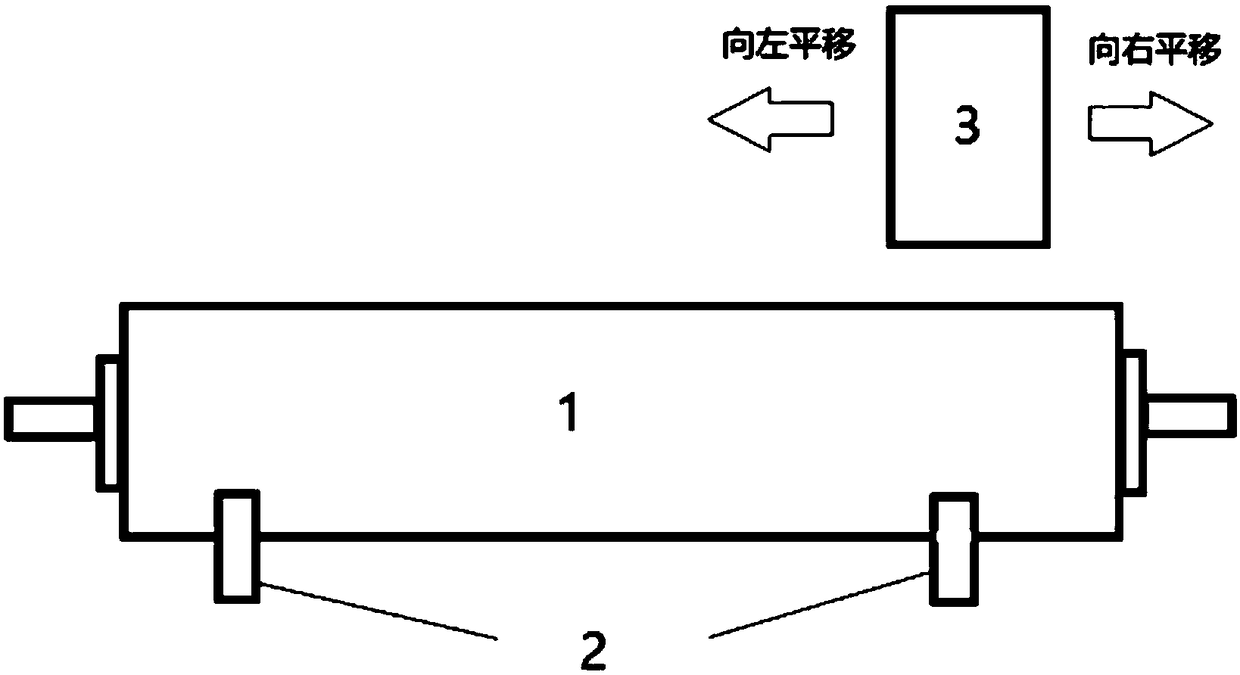

[0035] use as figure 1 The shown anilox roller cleaning device performs anilox roller cleaning: the device includes an anilox roller 1, a roller frame 2, a laser head 3, and a laser connected to the laser head 3 through an optical fiber, and the laser head 3 is provided with a scanning vibrator mirror. During use, the laser beam emitted on the laser head 3 is aimed at the anilox roller, and the laser device can reciprocate axially along the anilox roller; the anilox roller is a Pu polyurethane anilox roller, and The length is 1.62m.

[0036] The method includes cleaning the anilox roller with a pulsed laser, the wavelength of the pulsed laser is 1064nm, the pulse frequency is 25kHz, the power is 200W, the spot diameter of the pulsed laser is 1.0mm, and the scanning line width of the galvanometer is 140mm , the scanning frequency of the galvanometer is 85Hz, and the surface speed of the anilox roller is 15mm / s.

[0037] Such as figure 2 As shown, from top to bottom are the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com