Method for detecting and disposing faults in natural gas reforming hydrogen production system

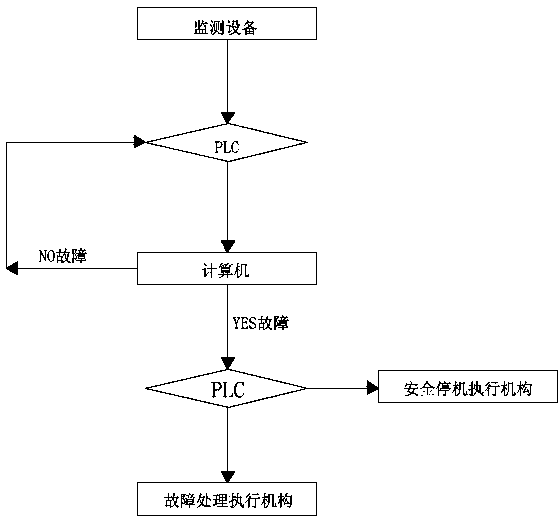

A technology of reforming hydrogen production and processing methods, which is applied in general control systems, control/regulation systems, and program control in sequence/logic controllers, etc., and can solve problems such as catalysts being easily polluted, economic losses, and unusable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

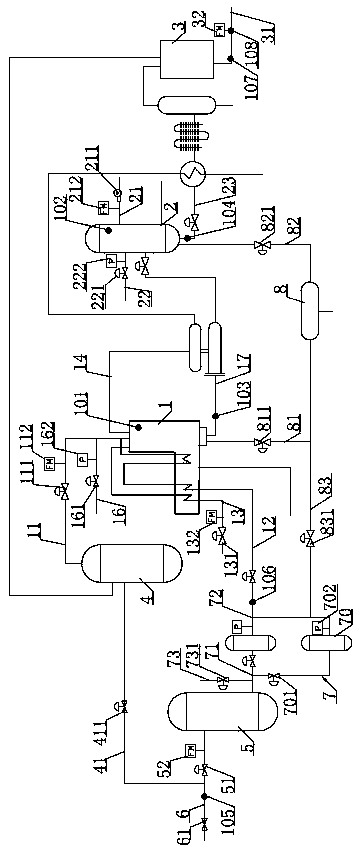

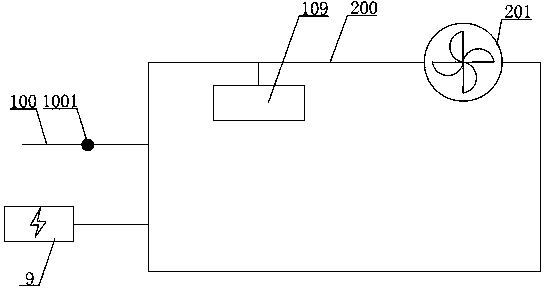

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: The temperature of the reformer is low.

[0039]The monitoring point 101 of the reformer temperature sends the monitoring signal to the PLC, and the PLC converts the monitoring signal into a measured value and sends it to the computer, and the computer obtains the measured value: T 实测 =700°C, the preset value T of the reformer temperature is preset in the computer 设定 =780℃, according to T 实测 设定 , the computer judged that the temperature of the reformer was low. In this embodiment, calculation processing is performed by the following method.

[0040] Calculation: △V=(△T / T 设定 ) × V 总 =0.43m 3 / h;

[0041] △Vair=λ△V=4.3 m 3 / h.

[0042] In the formula: △T is the difference between the temperature preset value and the measured temperature value; △V is the volume flow rate of natural gas for combustion that needs to be increased; T 设定 is the preset reformer temperature; V 总 is the initial volume flow rate of natural gas for combustion, V 总 =4.2m 3 / ...

Embodiment 2

[0044] Embodiment 2: Fault due to high sulfur content.

[0045] The monitoring point 106 of the natural gas composition after desulfurization sends the monitoring signal to the PLC, and the PLC converts the monitoring signal into a measured value and sends it to the computer, and the computer obtains the measured value of the sulfur content of the natural gas after desulfurization: S 实测 =8ppb, the preset value S of sulfur content in natural gas after desulfurization is preset in the computer 设定 =4ppb, according to S 实测 >S 设定 , the computer judged that a high sulfur content fault occurred.

[0046] According to △S=8-4=4ppb, the computer judges that the desulfurization treatment capacity needs to be doubled.

[0047] The computer sends instructions to the desulfurizer electric flow regulating valve 701 on a spare desulfurization pipeline through the PLC, so that the desulfurizer electric flow regulating valve 701 on the spare desulfurization pipeline is opened to a certain op...

Embodiment 3

[0048] Embodiment 3: The temperature of the carbon monoxide converter is too high and the fault occurs.

[0049] The monitoring point 102 of the temperature of the carbon monoxide converter sends the monitoring signal to the PLC, and the PLC converts the monitoring signal into a measured value and sends it to the computer, and the computer obtains the measured value of the temperature of the carbon monoxide converter: T 实测 =300℃, the preset value T of the carbon monoxide converter temperature is preset in the computer 设定 =280℃, according to T 实测 >T 设定 , the computer judges that the temperature of the carbon monoxide converter is too high. In this embodiment, calculation processing is performed by the following method.

[0050] Calculation: △V=(△T / T 设定 ) × V 导热油 =0.07 m / s.

[0051] In the formula: △T is the difference between the preset value and the measured value of the carbon monoxide converter temperature, △T=20℃; T 设定 is the preset value of carbon monoxide converter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com