Rubber-doped water-permeable cement concrete and preparation method thereof

A technology for permeable cement and concrete, applied in the field of cement concrete pavement materials, can solve problems such as insufficient strength of rubber permeable concrete materials, and achieve the effects of increasing strength, increasing compactness, and improving gradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

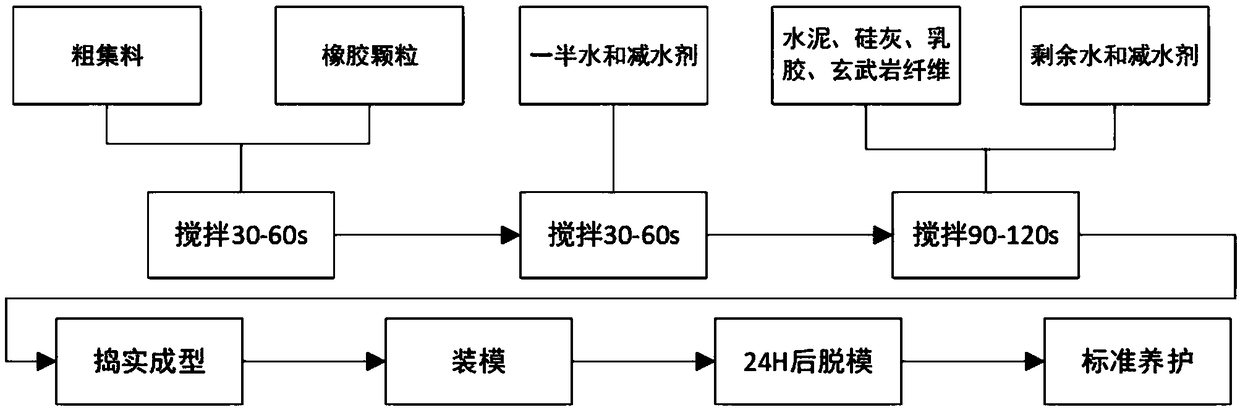

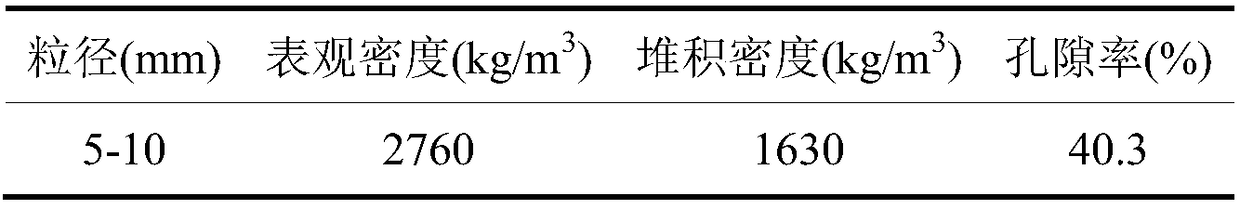

[0028] A permeable cement concrete mixed with rubber disclosed in the embodiment of the present invention comprises the following components in parts by weight: 1100-1400 parts of aggregate; 160-480 parts of waste rubber particles; 360-500 parts of cement; 90 parts of water -125 parts; 10-20 parts of latex; 15-30 parts of silica fume; 5-15 parts of basalt fiber; 3-4 parts of water reducing agent. Its preparation method is as figure 1 As shown, it mainly includes the following steps:

[0029] (1) Put the rubber particles in a metal container, add a silane coupling agent with a mass fraction of 1.5% of the rubber particles, add water to dissolve fully, stir fully to ensure that the rubber particles are in full contact with the silane coupling agent solution, and place in a dry place Wait until the surface of the rubber particles is completely dry in the environment.

[0030] (2) Prepare the above-mentioned required materials, mix the aggregate and rubber particles evenly, pour...

Embodiment 1

[0067] Example 1: permeable concrete mixed with rubber, including aggregate, waste rubber particles, cement, water, latex, silica fume, basalt fiber and high-efficiency water reducer. Each material is calculated in parts by weight, and the content of each component is shown in Table 4. The waste rubber particles are treated with KH560 silane coupling agent with a mass fraction of 1%-1.5%.

Embodiment 2

[0068] Embodiment 2: permeable concrete mixed with rubber, the difference from embodiment 1 is that the content of aggregate is reduced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap