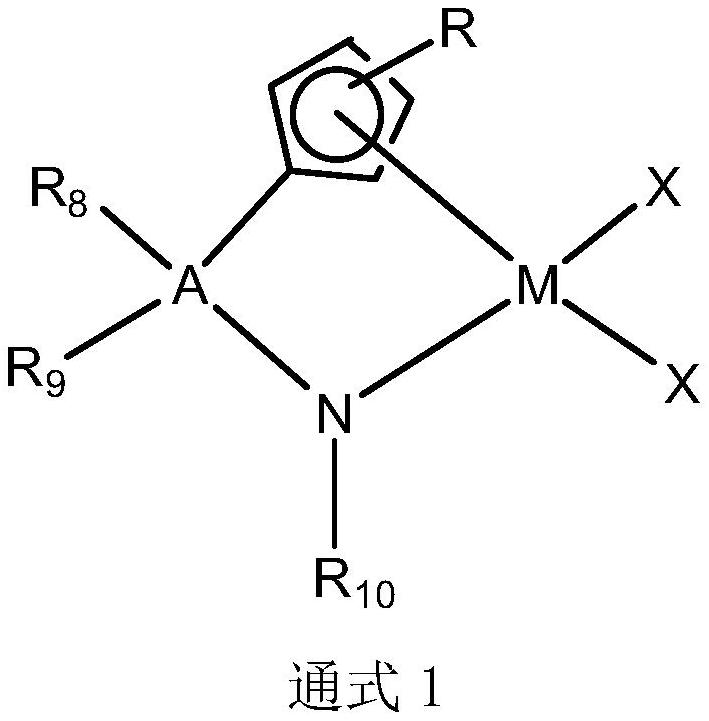

Metallocene catalyst, preparation method and application

A technology of metallocene catalysts and compounds, applied in the field of olefin coordination polymerization catalysts, can solve the problems of high price and poor performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

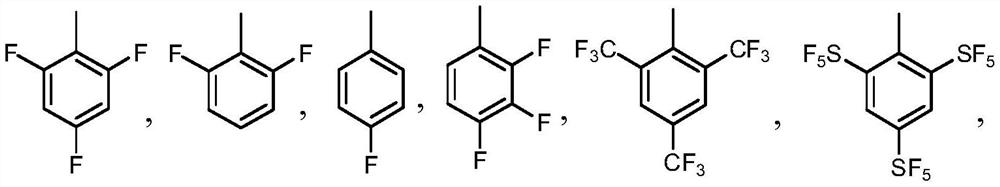

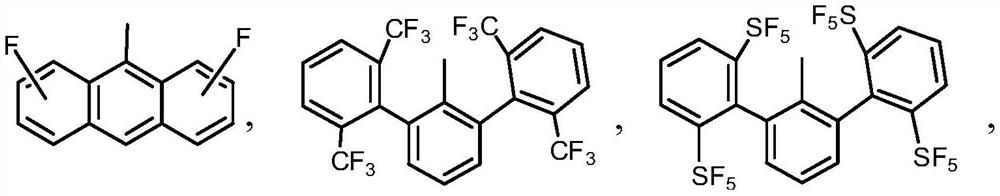

Method used

Image

Examples

Embodiment 1

[0056] After fully replacing the 2-liter stainless steel autoclave with nitrogen, add 1L of n-hexane to the reaction kettle, add 3mg of metallocene catalyst (1), 3mL of MAO (10% toluene solution), fill with 0.1L of hydrogen, and fill with ethylene to pressure 0.7MPa, stirred, raised the temperature to 125°C for 2 hours, and collected 286 grams of polymerization product.

Embodiment 2

[0058]After the 2-liter stainless steel autoclave was fully replaced by nitrogen, 1 L of n-heptane was added to the reaction kettle, 5 mg of catalyst (2), 2 mL of modified MAO (10% toluene solution), 60 mL of 1-hexene, and 0.05 L was filled with ethylene to a pressure of 0.8 MPa, stirred, heated to 135°C for 2 hours, and 262 grams of polymerization products were collected.

Embodiment 3

[0060] After fully replacing the 2-liter stainless steel autoclave with nitrogen, add 1 L of n-hexane, 2 mg of metallocene catalyst (3), 2 mL of modified MAO (10% toluene solution), 60 mL of 1-hexene into the reaction kettle, and fill with hydrogen 0.1L, add 0.5kg of propylene, fill with ethylene until the pressure is 0.7MPa, stir, raise the temperature to 110°C for 2 hours, and collect 275g of polymerization product.

PUM

| Property | Measurement | Unit |

|---|---|---|

| aggregation | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com