Method and device for refining oil from papermaking waste

A waste and waste plastic technology, applied in the field of papermaking waste oil refining method and device, can solve environmental pollution and other problems, achieve good social benefits, and the overall structure is scientific and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

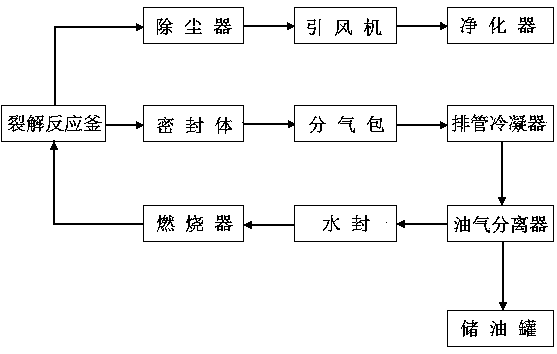

[0021] refer to figure 1 , a kind of papermaking waste refining method of the present invention, it comprises the following steps:

[0022] 1) Waste sorting: use sorting equipment to sort out waste plastics in papermaking waste, including using magnetic sorting to remove iron-containing substances in papermaking waste;

[0023] 2) Raw material pretreatment: crush and melt the sorted waste plastics, and transport them to the pyrolysis reactor. The particle size of the waste plastics after crushing and melting should be controlled within the range of 8-12mm, It is beneficial to improve the speed of the subsequent catalytic cracking reaction, as well as ensure the complete reaction and high utilization rate of raw materials;

[0024] 3) Catalytic cracking: add metal oxides into the reactor as a catalyst, stir and mix the waste plastics in the reactor with the catalyst to carry out catalytic cracking reaction to obtain oil gas and ash, and the ash is discharged through the reacto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com