High temperature-resistant bacterium for promoting ammonia assimilation function in sludge composting process

An assimilation, high temperature-resistant technology, applied in bacteria, microorganism-based methods, biochemical equipment and methods, etc., can solve problems such as nitrogen loss, limiting the application and promotion of sludge composting, affecting the air quality of production workshops, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

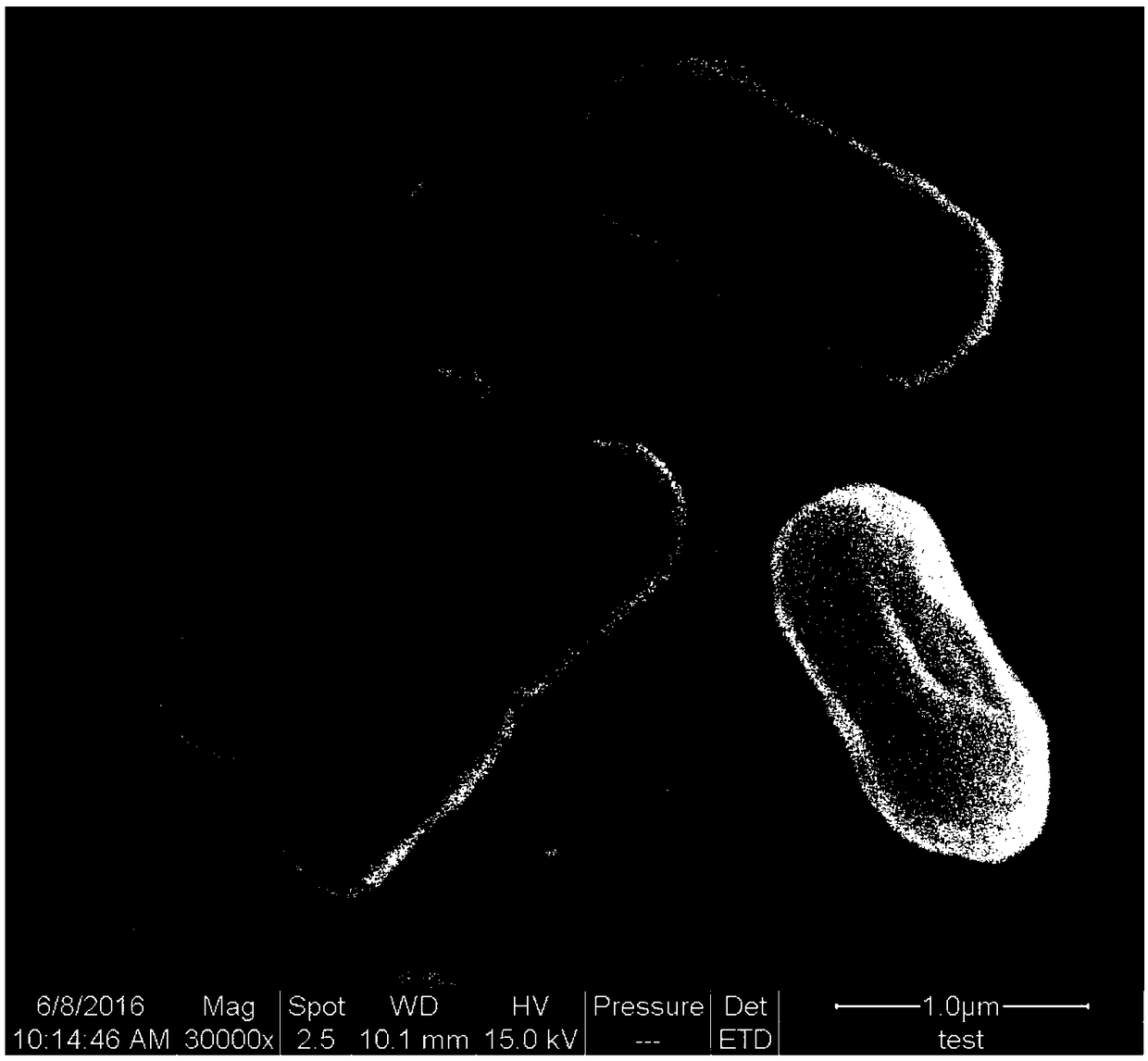

Image

Examples

specific Embodiment approach 1

[0014] Specific Embodiment 1: In this embodiment, Bacillus mojavensis P2 is isolated from the sewage treatment sludge of Harbin Wenchang Sewage Plant.

[0015] Isolation and purification of Bacillus mojavensis P2:

[0016] Take 1.0g sample of sewage plant sludge composting in the high temperature period, put it in 100mL sterile water, add glass beads and shake it well, take the supernatant to dilute in sequence, and then take 10 -6 、10 -7 、10 -8 Spread 100 μL of the diluted solution on the separation medium plate, and incubate in a 50°C incubator for 72 hours. After colonies are visible to the naked eye, pick a single colony for further purification;

[0017] The purified single colony was picked and inserted into the sludge extract medium to detect the ability to assimilate ammonia nitrogen, and the strain with the strongest ammonia assimilation ability was selected as P2. (The same inoculum size, the same culture time and different strains on the NH in the medium 4 + Th...

Embodiment 1

[0024] compost:

[0025] One, Bacillus mojavensis (Bacillus mojavensis) P2 is inoculated into liquid medium A in test tube (liquid medium A comprises 0.25% sodium acetate, 0.05% ammonium nitrate, 0.025% ferric ammonium citrate, 0.1 % sodium chloride, 0.25% dipotassium hydrogen phosphate, 0.05% dipotassium hydrogen phosphate, 0.025% magnesium sulfate and 0.005% manganese sulfate) for 24 hours, and then insert it into the Erlenmeyer flask with 1% inoculum Continue to expand the culture for 24 hours to form a bacterial suspension.

[0026] Wherein, all the culture medium for the expanded culture in the Erlenmeyer flask is liquid medium A.

[0027] 2. Add pumice with 50% fresh sludge quality to the fresh sludge of Harbin Wenchang Sewage Treatment Plant (taken from July 4, 2016) with a humidity of 80%, mix well, compost and ferment and force ventilation, the ventilation rate is 0.25 L / min·L, ferment for 48 ± 2 hours, add the Bacillus mojavensis P2 expanded in step 1 according to ...

Embodiment 2

[0030] compost:

[0031] Add pumice with 50% fresh sludge quality to the fresh sludge of Harbin Wenchang Sewage Treatment Plant (taken on July 4, 2016) with a humidity of 80%, mix well, compost and ferment, and force ventilation with a ventilation rate of 0.25L / min·L, 20 days of fermentation to complete the composting and fermentation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com