Method for improving function stability of nickel-titanium shape memory alloy

A technology of memory alloy and stability, which is applied in the field of nickel-titanium shape memory alloy, can solve problems such as the insignificant strength effect of the nickel-titanium shape memory alloy matrix, difficulty in handling nickel-titanium alloy components, and unsuitable nickel-titanium alloy components, etc., to achieve improvement Functional stability, improvement of matrix strength, and effect of improving functional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

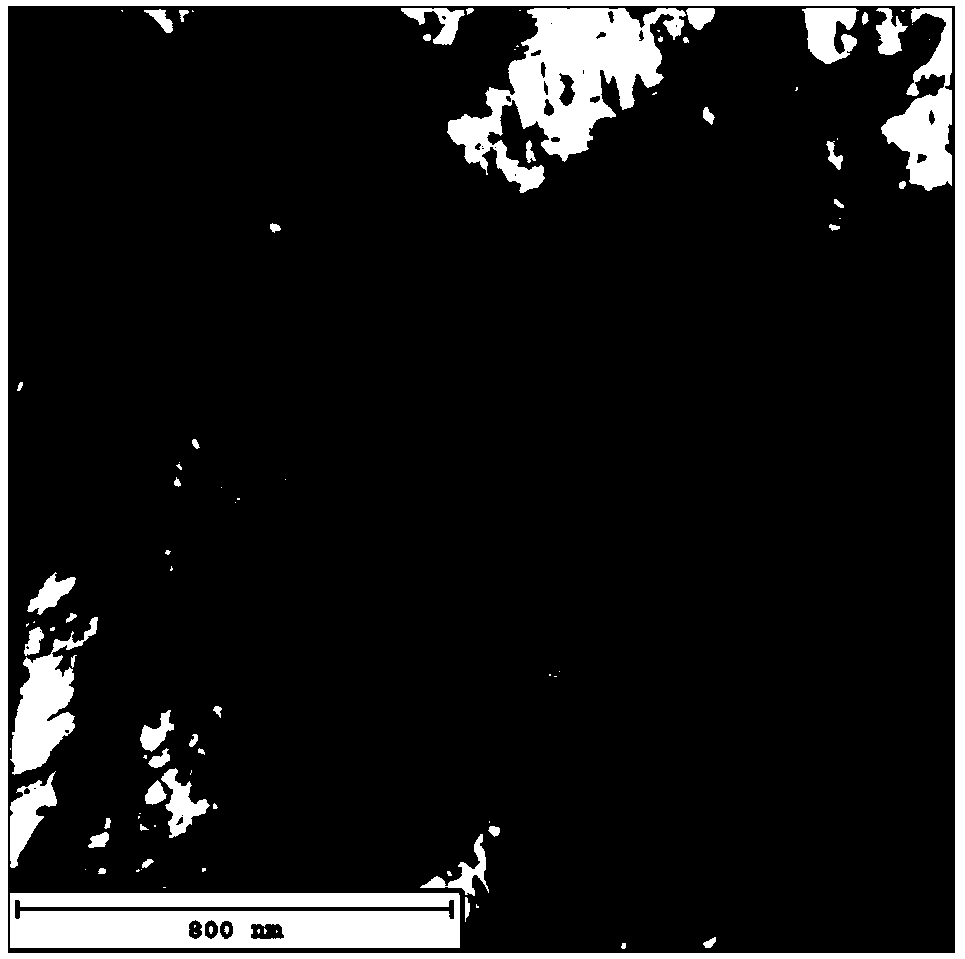

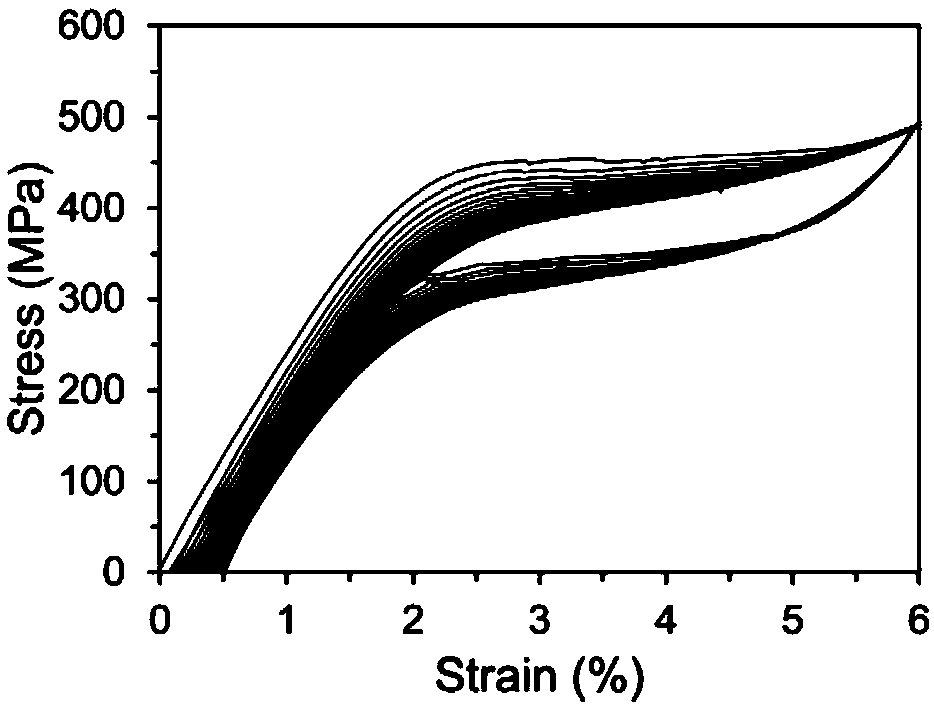

[0037] A method for improving the functional stability of a nickel-titanium shape memory alloy, comprising the steps of: first, stretching and deforming the nickel-titanium shape memory alloy to 9.5% at room temperature, then unloading, and repeating the above process 10 times, the nickel-titanium shape memory alloy Introducing dislocation defects; then aging for 48 hours under the condition of 250° C., introducing nanometer two-phase particles into the nickel-titanium shape memory alloy to obtain.

[0038] The atomic percentage of nickel in the nickel-titanium shape memory alloy used in this embodiment is 50.8 at.%.

Embodiment 2

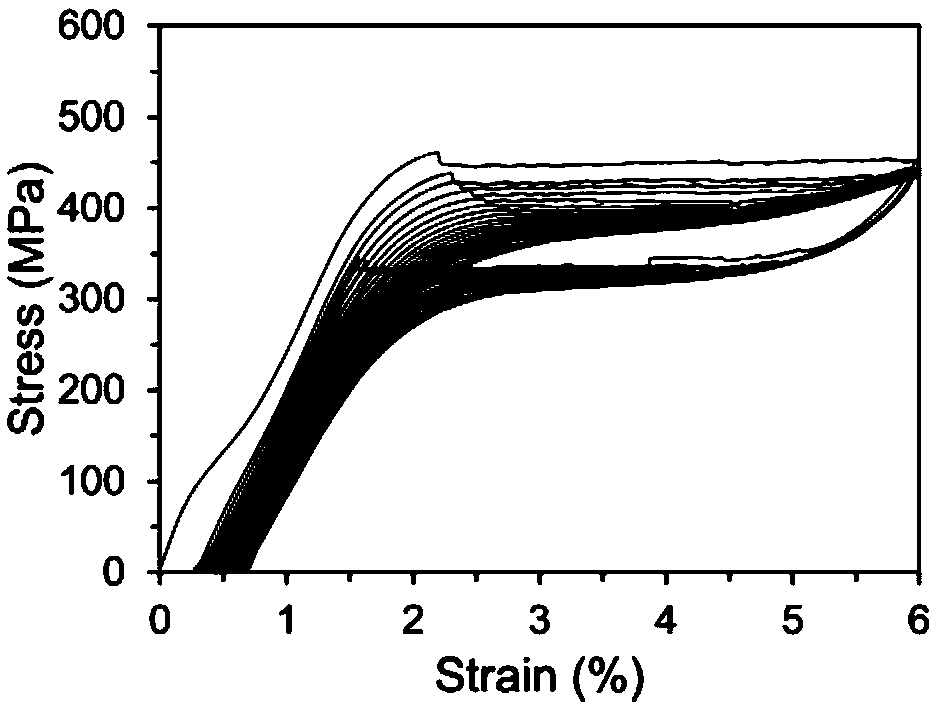

[0040] A method for improving the functional stability of a nickel-titanium shape memory alloy, comprising the following steps: first, keeping the nickel-titanium shape memory alloy in a water bath at 100° C. for 5 minutes, then putting it into liquid nitrogen for 5 minutes, and then putting it into the Keep warm in a water bath at 100°C for 5 minutes, repeat the above process 20 times, and introduce dislocation defects into the nickel-titanium shape memory alloy; then age at 250°C for 48 hours, and introduce nano-secondary phase particles into the nickel-titanium shape memory alloy, that is, .

[0041] The atomic percentage of nickel in the nickel-titanium shape memory alloy used in this embodiment is 50.8 at.%.

Embodiment 3

[0043] A method for improving the functional stability of a nickel-titanium shape memory alloy, comprising the following steps: first, keeping the nickel-titanium shape memory alloy in a water bath at 100° C. for 5 minutes, then putting it into liquid nitrogen for 5 minutes, and then putting it into the Keep warm in a water bath at 100°C for 5 minutes, repeat the above process 200 times, and introduce dislocation defects into the nickel-titanium shape memory alloy; then age at 150°C for 500 hours, and introduce nanometer two-phase particles into the nickel-titanium shape memory alloy. .

[0044] The atomic percentage of nickel in the nickel-titanium shape memory alloy used in this embodiment is 50 at.%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com