Vacuum hot pressing sintering preparation method of a high-purity tantalum-ruthenium alloy target

A technology of vacuum hot pressing sintering and ruthenium alloy, applied in the direction of vacuum evaporation plating, metal material coating process, coating, etc., can solve the problems of high cost of electron beam smelting equipment, affecting the performance of later products, and huge power matching. Achieve the effects of easy guarantee of target purity, stable microstructure and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] A method for preparing a high-purity tantalum-ruthenium alloy target by vacuum hot-pressing sintering, comprising the following steps:

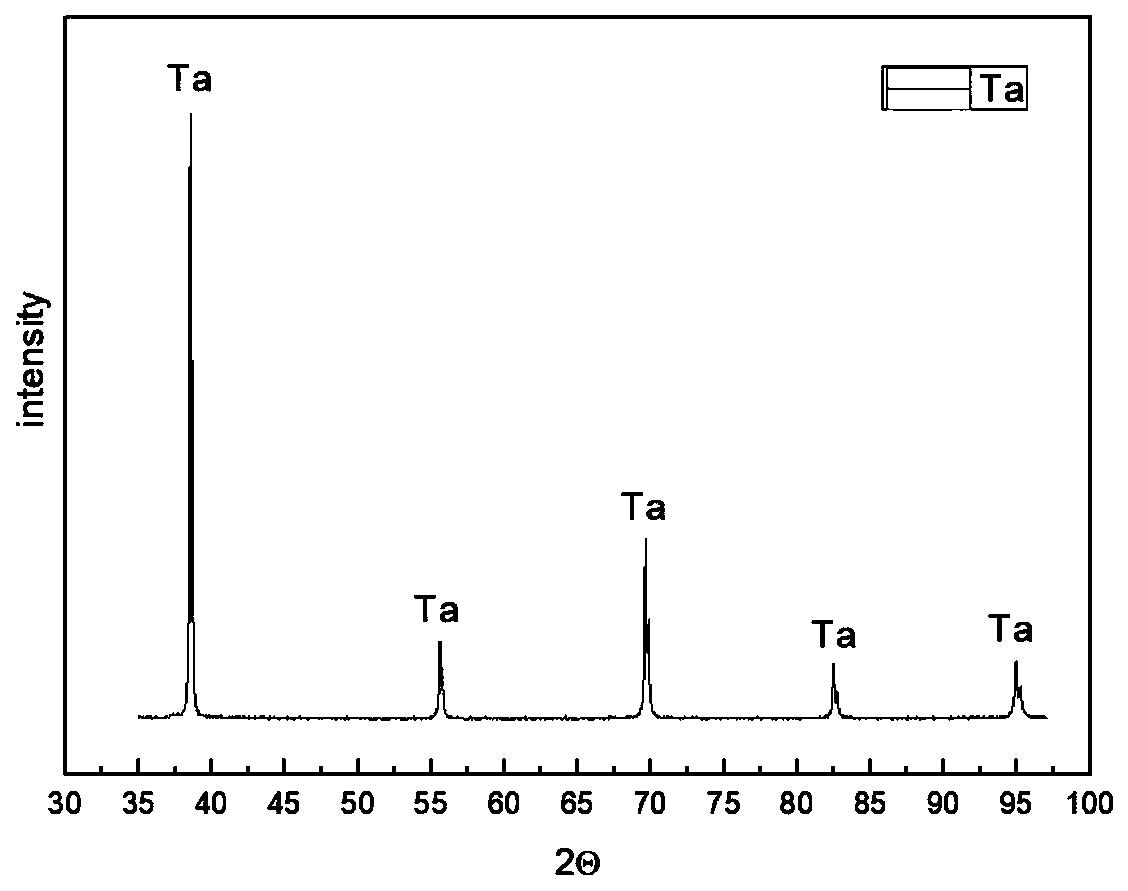

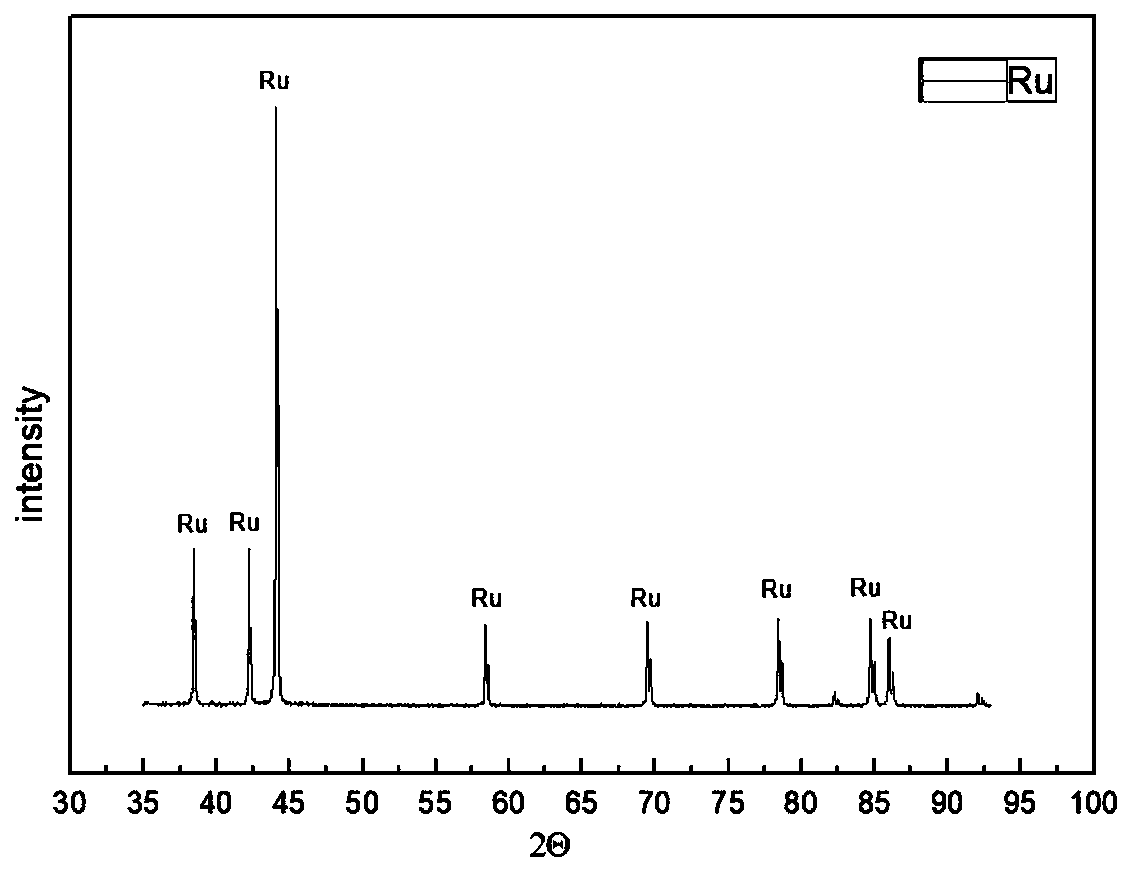

[0039] (1) Crushing: respectively break the high-purity tantalum block and ruthenium block with a purity >99.95% into powders with a particle size of <2 mm, and sieve to obtain tantalum powder and ruthenium powder;

[0040] (2) Ball milling: Fill 99% nitrogen into the ball milling jar, under the protection of nitrogen, the tantalum powder and ruthenium powder obtained in step (1) are respectively ball milled until the particle size is 5-200 μm, and the volume average particle diameter is 50μm;

[0041] (3) Mixing: distribute the tantalum powder and ruthenium powder after ball milling in step (2) respectively according to the same standard, and take the powders whose particle size distribution is ≤50 μm, 80-150 μm and 160-200 μm during distribution. Powder, distributed according to the mass ratio of 2-3:3-4:1; then mixed according to t...

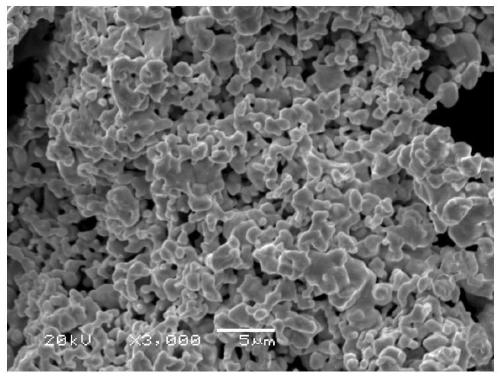

Embodiment 1

[0057] The industrially purified high-purity tantalum block and ruthenium block with a purity >99.95% are crushed into small particles of 3 ; The surface of the high-purity tantalum-ruthenium body is processed, and the size is processed according to the magnetron sputtering equipment to obtain a high-purity tantalum-ruthenium target.

Embodiment 2

[0059] The industrially purified high-purity tantalum and ruthenium blocks with a purity >99.95% are crushed into small particles of 3 ; The surface of the high-purity tantalum-ruthenium body is processed, and the size is processed according to the magnetron sputtering equipment to obtain a high-purity tantalum-ruthenium target.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com