Non-interference and high-stability ribbon loom weft insertion device

A high-stability, weft-inserting device technology, used in textiles, textiles, papermaking, shuttles, etc., can solve the problems of insufficient stability, poor product quality, imperfect structure, etc., and achieve improved webbing quality and device life. Simple structure , routing and corresponding structural design optimization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

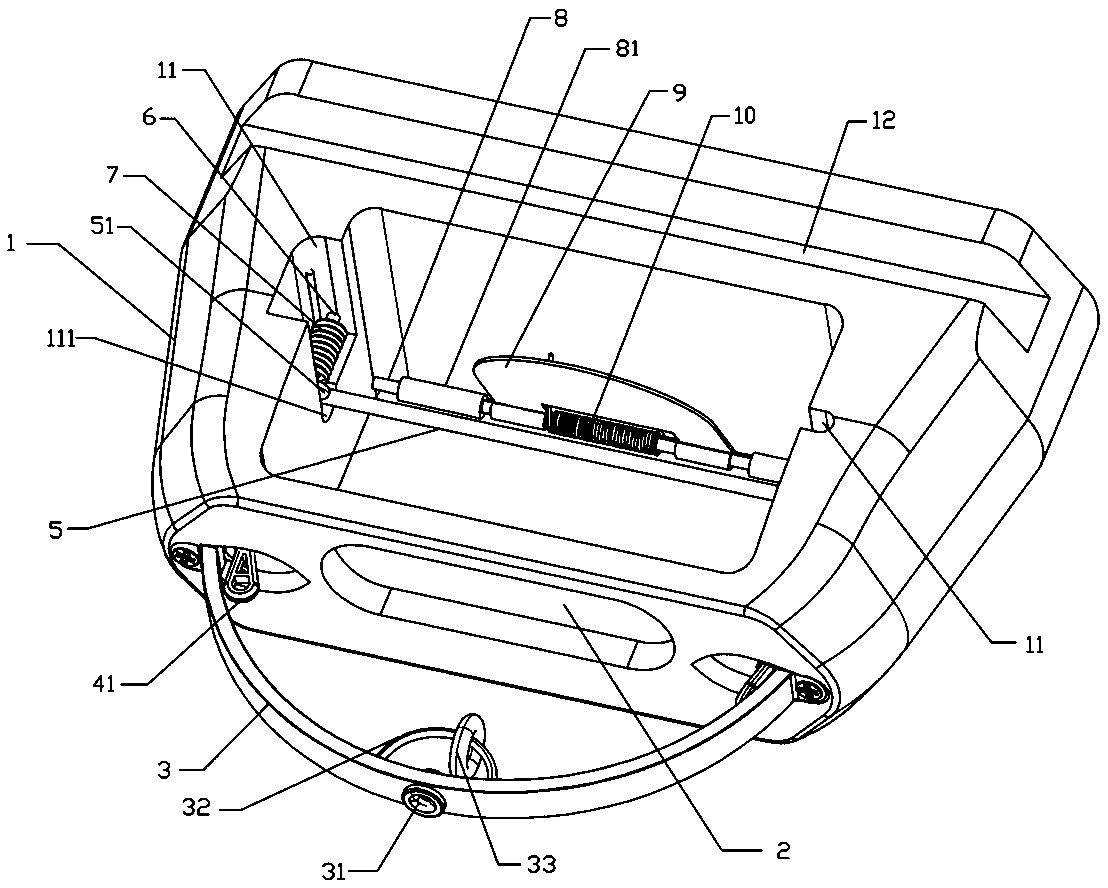

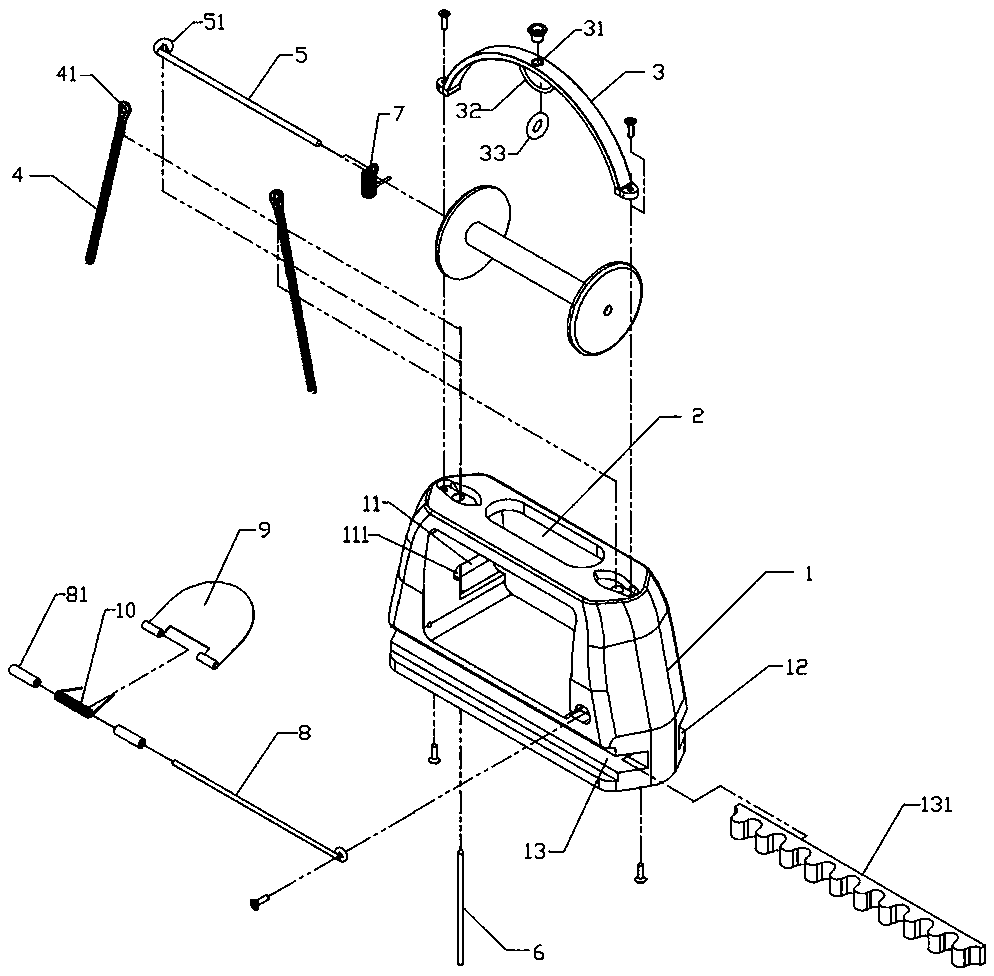

[0035] Embodiment one: see figure 1 , figure 2 , a weft insertion device for a loom without interference and high stability, including a shuttle body 1, the upper surface of the rear end of the shuttle body 1 is provided with an upper guide part 12 for wooden foot connection (there will be wooden foot components on the shuttle box, usually divided into The structure of the upper wooden leg and the lower wooden leg, the upper wooden leg is generally provided with a guide strip, and the lower wooden leg is provided with a guide wheel, and the whole is relatively slidingly connected with the shuttle body 1), and the upper wooden leg is connected with the upper guide part 12 includes the upper guide groove. Of course, there is no guide bar on the wooden foot but a guide groove is provided. Then the upper guide part 12 for wooden foot connection can be changed to an upper guide strip accordingly. The diagram only shows the way of the upper guide groove The lower surface of the sh...

Embodiment 2

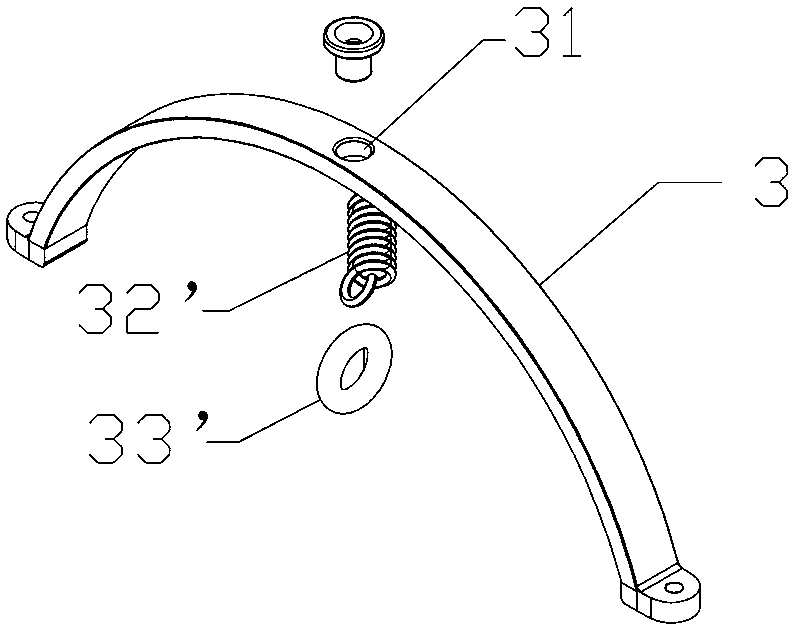

[0040] Embodiment two: see image 3 The difference between this embodiment and Embodiment 1 is that the follow-up mechanism includes an elastic member 32' connected to the inner wall of the support frame 3 itself on the side of the weft thread passing space and a weft threading ring 33 connected to the end of the elastic member 32' ', is another implementation of the follow-up mechanism.

Embodiment 3

[0041] Embodiment three: see Figure 4 The difference between this embodiment and Embodiment 1 is that the follow-up mechanism includes a swing rod 32'' hinged to the inner wall of the support frame 3 itself on the side of the weft thread passing space and a weft passing rod connected to the end of the swing rod 32''. The ring 33'' is another implementation of the follow-up mechanism.

[0042] See Figure 5 (The thicker line is the weft thread). The weft thread lead-out component and the weft thread pull-back component cooperate with each other to complete the weft insertion. The weft thread has a corresponding threading method in this technical solution: the weft thread comes out from the weft thread path, and first passes through the weft thread. Move the weft threading ring 33, then pass the thread passing head 41 on one side, then pass the thread passing head 41 on the other side, and finally pass the weft outlet 31. In the actual working process, the entire shuttle body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com