Roadbed surface dehumidifier

A technology of roadbed surface and dehumidifier, applied in roads, roads, buildings, etc., can solve problems such as shortening the service life of roads, road diseases and increasing maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

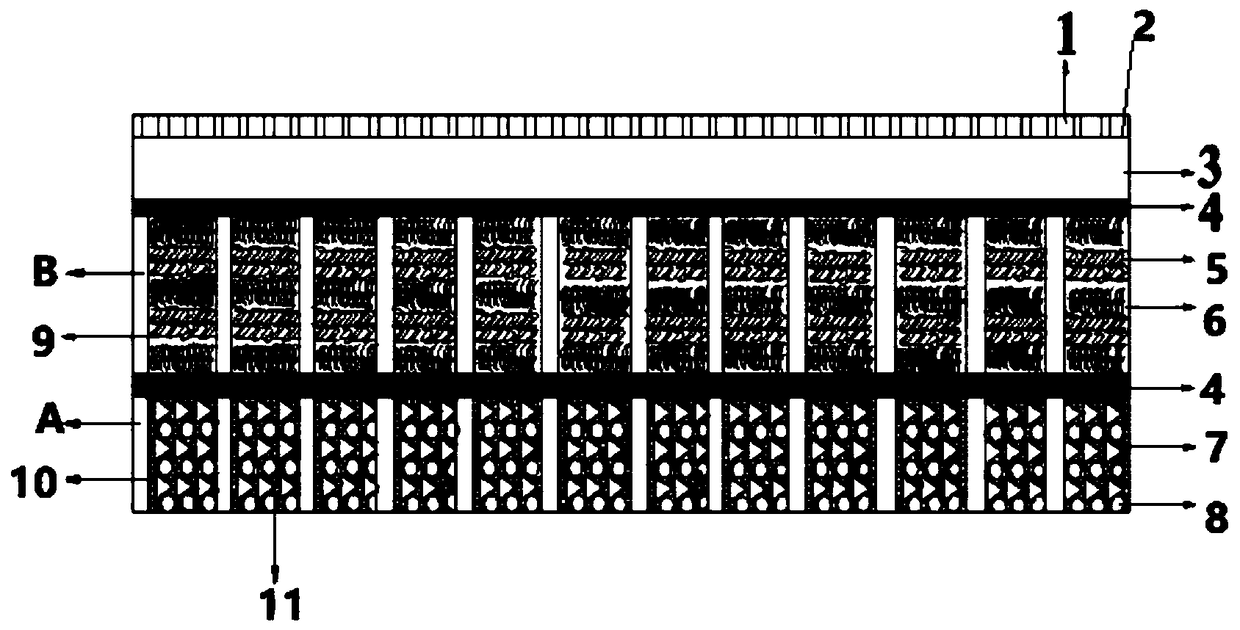

[0070] (1) Pour the four components of sodium polyacrylate, polyacrylamide, anhydrous calcium chloride and attapulgite into the mixer and mix for 300s to form a hygroscopic agent, and then put the hygroscopic agent into the material preparation tank.

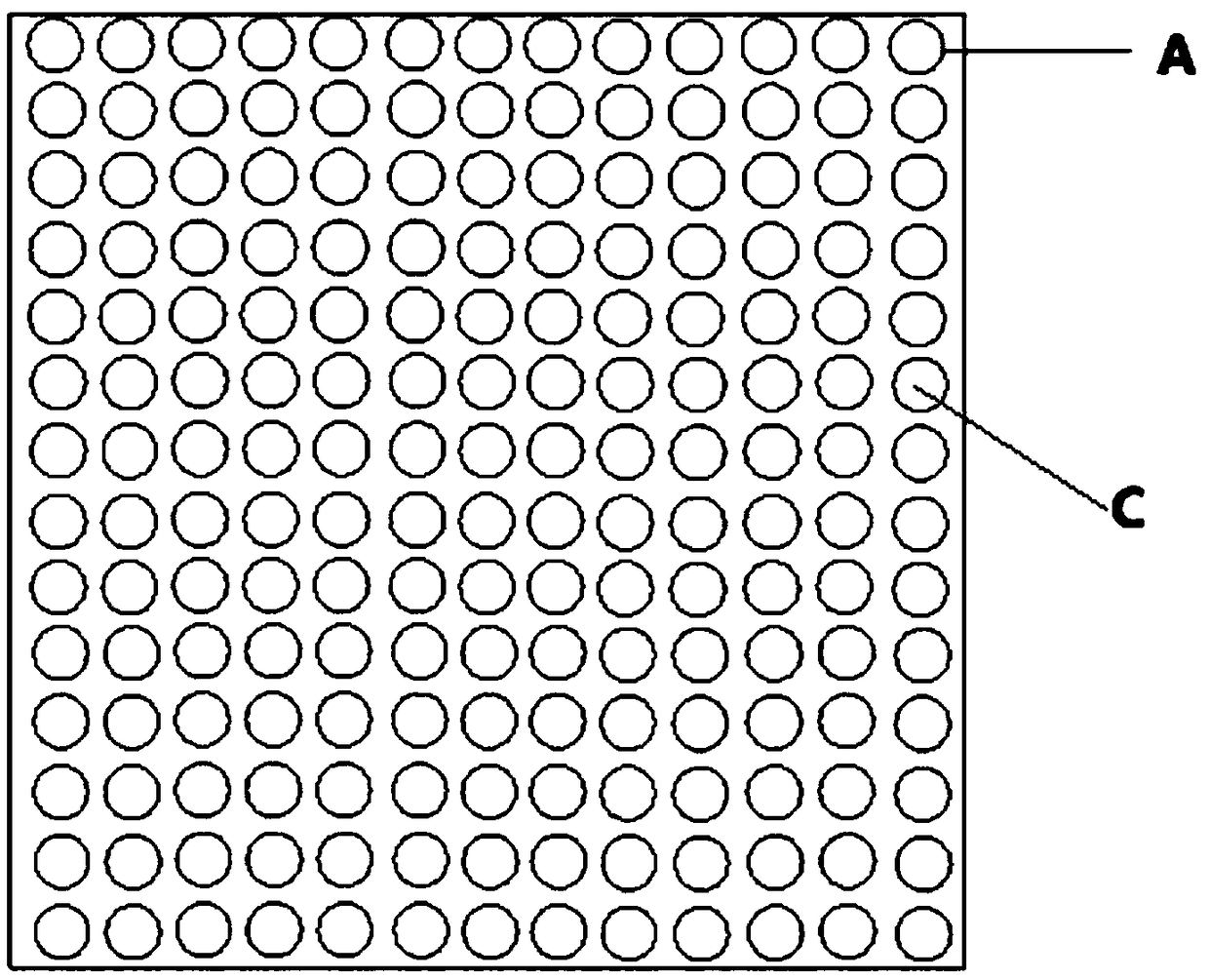

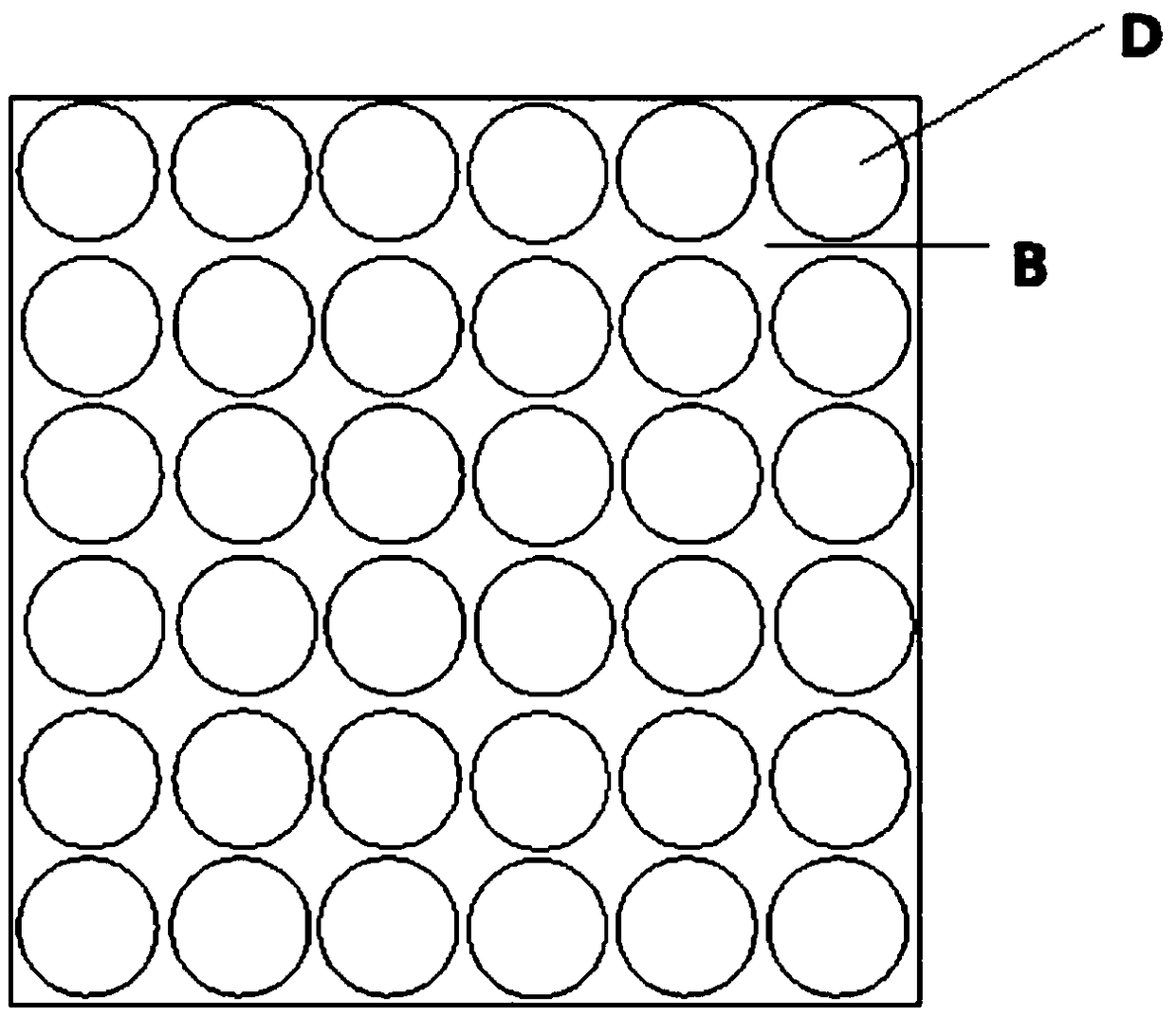

[0071] (2) Take a corresponding mold according to the single hole size of the first substrate, pour the hygroscopic agent in step (1) into the corresponding mold, and use a compression molding machine to press the mixture into a cylindrical hygroscopic agent.

[0072] (3) Insert the pressed cylindrical hygroscopic agent into each cylindrical hole of the first substrate, and evenly coat the first surface (non-hole surface area) and the second surface (non-hole surface area) of the first substrate Acrylate emulsion polymer, with a saturated impregnated nonwoven bonded on the first side for contact with the subgrade surface.

[0073] (4) Take by weighing an appropriate amount of chopped viscose fiber, bamboo fiber and viscose-based...

Embodiment 2

[0078] (1) Pour the four components of sodium polyacrylate, polyacrylamide, anhydrous calcium chloride, and attapulgite into the mixer and mix for 300s to form a hygroscopic agent, and then put the hygroscopic agent into the material preparation tank.

[0079] (2) Take a corresponding mold according to the single hole size of the first substrate, pour the hygroscopic agent in step (1) into the corresponding mold, and use a compression molding machine to press the mixture into a cylindrical hygroscopic agent.

[0080] (3) Insert the pressed cylindrical hygroscopic agent into each cylindrical hole of the first substrate, and evenly coat the first surface (non-hole surface area) and the second surface (non-hole surface area) of the first substrate Acrylate emulsion polymer, with a saturated impregnated nonwoven bonded on the first side for contact with the subgrade surface.

[0081] (4) Take by weighing an appropriate amount of chopped viscose fiber, bamboo fiber and viscose-base...

Embodiment 3

[0086] (1) Pour the four components of sodium polyacrylate, polyacrylamide, anhydrous calcium chloride, and attapulgite into the mixer and mix for 300s to form a hygroscopic agent, and then put the hygroscopic agent into the material preparation tank.

[0087] (2) Take a corresponding mold according to the single hole size of the first substrate, pour the hygroscopic agent in step (1) into the corresponding mold, and use a compression molding machine to press the mixture into a cylindrical hygroscopic agent.

[0088] (3) Insert the pressed cylindrical hygroscopic agent into each cylindrical hole of the first substrate, and evenly coat the first surface (non-hole surface area) and the second surface (non-hole surface area) of the first substrate Acrylate emulsion polymer, with a saturated impregnated nonwoven bonded on the first side for contact with the subgrade surface.

[0089] (4) Take by weighing an appropriate amount of chopped viscose fiber, bamboo fiber and viscose-base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com