Rock wool production weighing belt device and rock wool board production line

A belt device and weighing technology, used in measuring devices, weighing equipment for continuous material flow, weighing, etc., can solve the problems of not being able to be well monitored, and the weight of rock wool fluctuates greatly, reducing the self-weight of the equipment. , convenient for accurate measurement, accurate weight control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

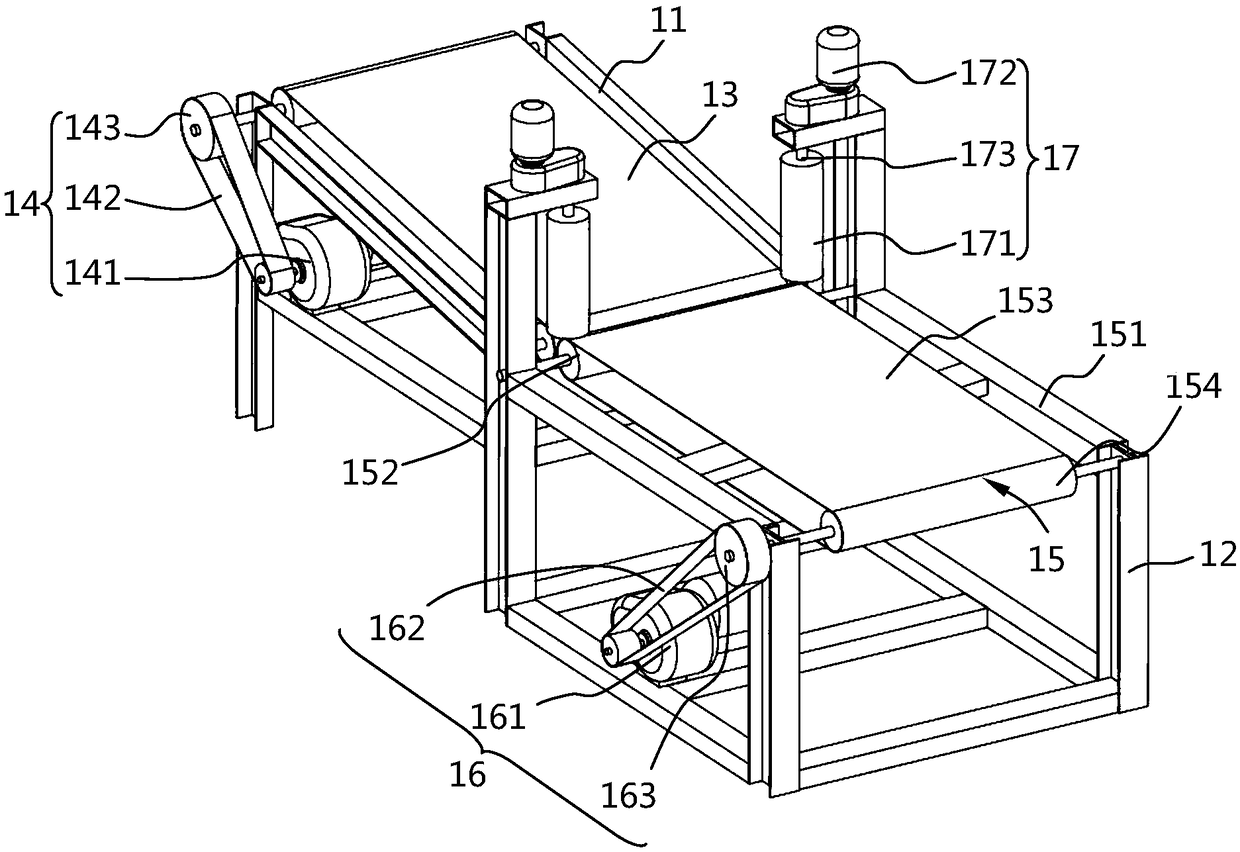

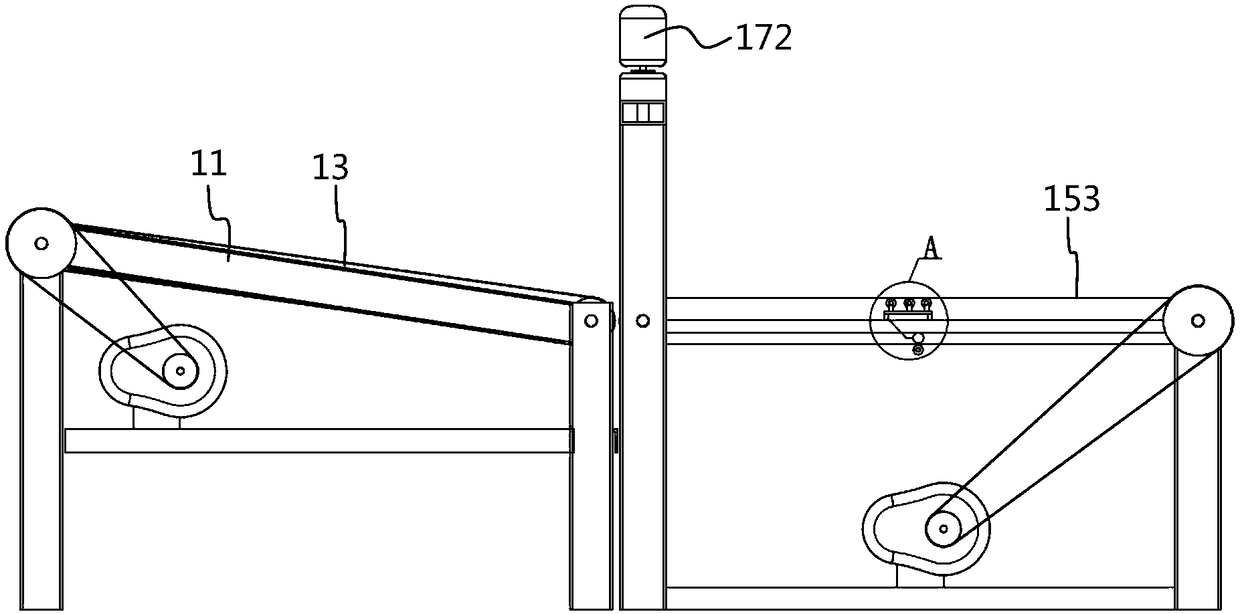

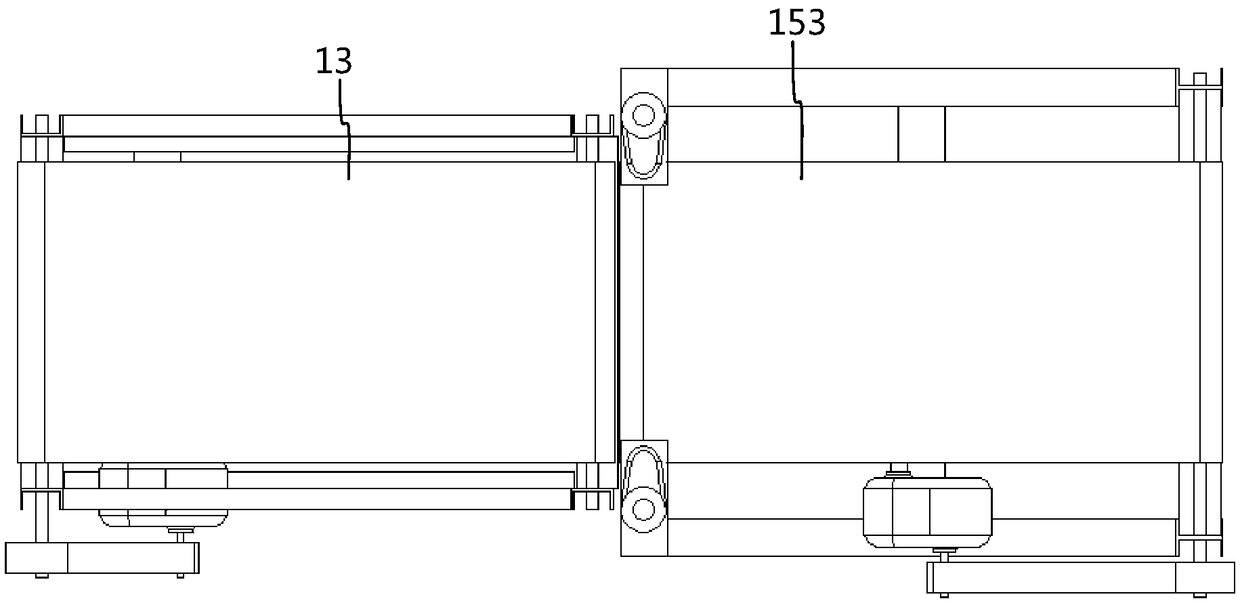

[0050] see Figure 1 to Figure 5 , describe the rock wool production weighing belt device according to a preferred embodiment of the present invention, wherein, figure 1 It is a schematic structural representation of rock wool production weighing belt device of the present invention; figure 2 The side view of weighing belt device for rock wool production of the present invention; image 3 The top view of rock wool production weighing belt device of the present invention; Figure 4 It is the front view of the rock wool production weighing belt device of the present invention; Figure 5 for figure 2 Enlarged view of part A.

[0051] Such as Figure 1 to Figure 5 As shown, a weighing belt device for rock wool production in this embodiment includes a first frame 11, which has a mounting frame, which is set at a certain inclination angle, and the inclination angle of the mounting frame is 30-45°, the best The inclination angle of the installation frame is 40°; the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com