Air tightness surface acoustic wave element package structure and manufacturing method thereof

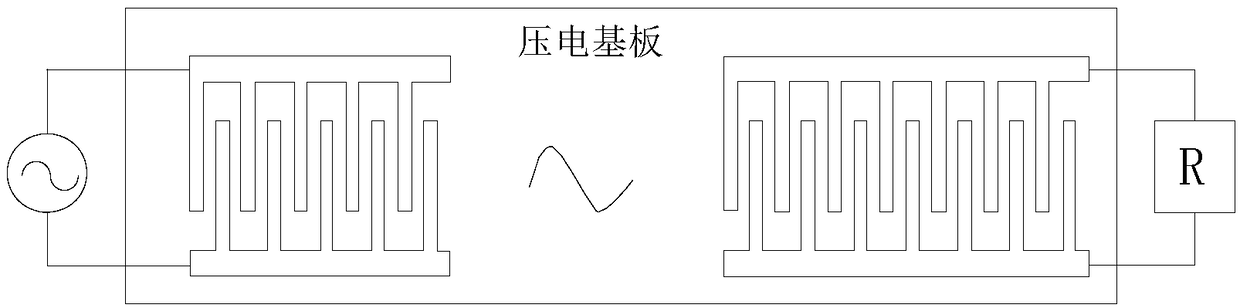

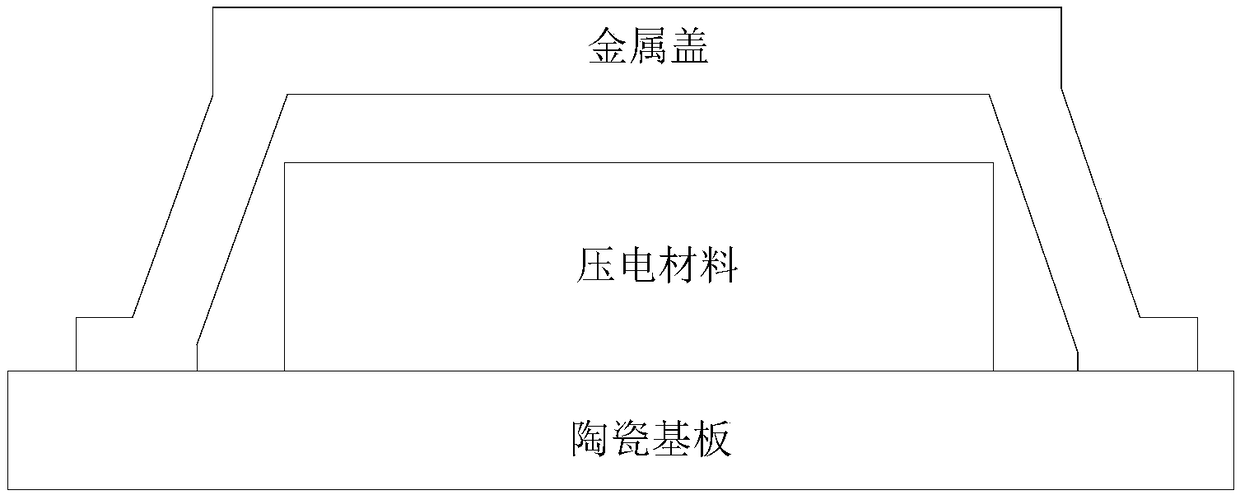

A surface acoustic wave, packaging structure technology, applied in electrical components, impedance networks, etc., can solve problems such as large differences in expansion coefficients, limiting process throughput, and difficulty in cutting piezoelectric wafers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

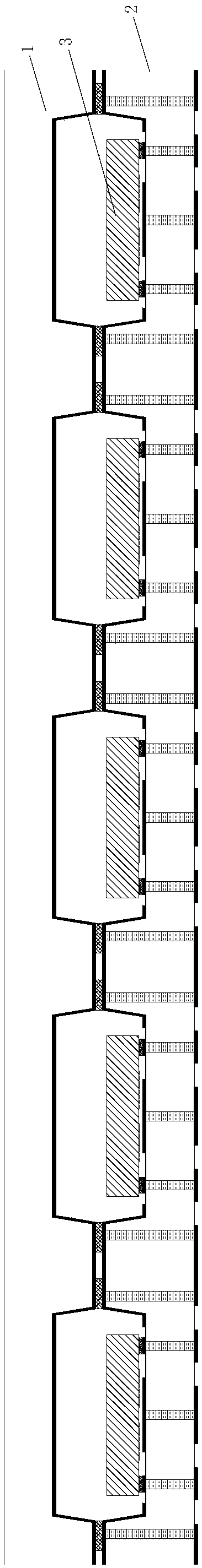

[0156] like Figure 3 ~ Figure 7 As shown, this embodiment provides an airtight surface acoustic wave element packaging structure, which includes an upper glass cover array 1 , a lower glass substrate array 2 and five surface acoustic wave chips 3 .

[0157] The upper glass cover array 1 has five upper glass cover plates 11, each upper glass cover plate 11 corresponds to a surface acoustic wave chip 3, which includes a first glass body 111, and the first glass body 111 etches a first Groove 112, the first groove 112 is facing the corresponding surface acoustic wave chip 3, and the first conductive layer is deposited on the inner surface of the etched first glass body 111, specifically, the first conductive layer is generally made of copper, molybdenum, Made of tungsten, aluminum copper, nickel, etc., the first metal layer 113 is electroplated on the first conductive layer. The first metal layer 113 is made of copper material, which realizes the electromagnetic shielding of the...

Embodiment 2

[0194] The main features of the package structure of the hermetic surface acoustic wave element in this embodiment are as follows: Figure 10 ~ Figure 12 As shown, each upper glass cover 11 of the upper glass cover array includes a first glass body 111, a first conductive layer is deposited on the inner surface of the first glass body 111, and a first metal layer 112 is electroplated on the first conductive layer. , preferably, the surface of the upper glass cover 11 can also be protected with metals such as nickel-palladium-gold, nickel-gold, silver, etc.; furthermore, the upper glass cover 11 can also be printed with an adhesive 113 after metallization. The mixture 113 can align and press the upper glass cover array and the lower glass substrate array; each lower glass substrate 21 includes a second glass body 211, and the second glass body 211 is etched with grooves 212 and through holes 213. The slot 212 is used to mount the corresponding surface acoustic wave chip 3, and ...

Embodiment 3

[0222] The main features of the package structure of the hermetic surface acoustic wave element in this embodiment are as follows: Figure 13 ~ Figure 15 As shown, each upper glass cover 11 of the upper glass cover array includes a first glass body 111, and the first glass body 111 is etched with a groove 112, the groove 112 is facing the corresponding surface acoustic wave chip 3, and the etched The first conductive layer is deposited on the inner surface of the first glass body 111, and the first metal layer 113 is electroplated on the first conductive layer. Preferably, metals such as nickel palladium gold, nickel gold, and silver can also be used on the surface of the upper glass cover plate 11. protection; further, the upper glass cover plate 11 can also be printed with adhesive 114 after metallization, and the upper glass cover plate array and the lower glass substrate array can be aligned and pressed through the adhesive 114; The glass substrate 21 includes a second gla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com