Weed-killing composition containing tefuryltrione-oxaziclomefone-sulfonylurea weed killers

A technology of furansulcotrione and herbicidal composition, which is applied in the direction of herbicides, algicides, biocides, biocides, etc., which can solve the problems of complex grass, weed resistance, etc., to reduce pollution and prolong the use The effect of life and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

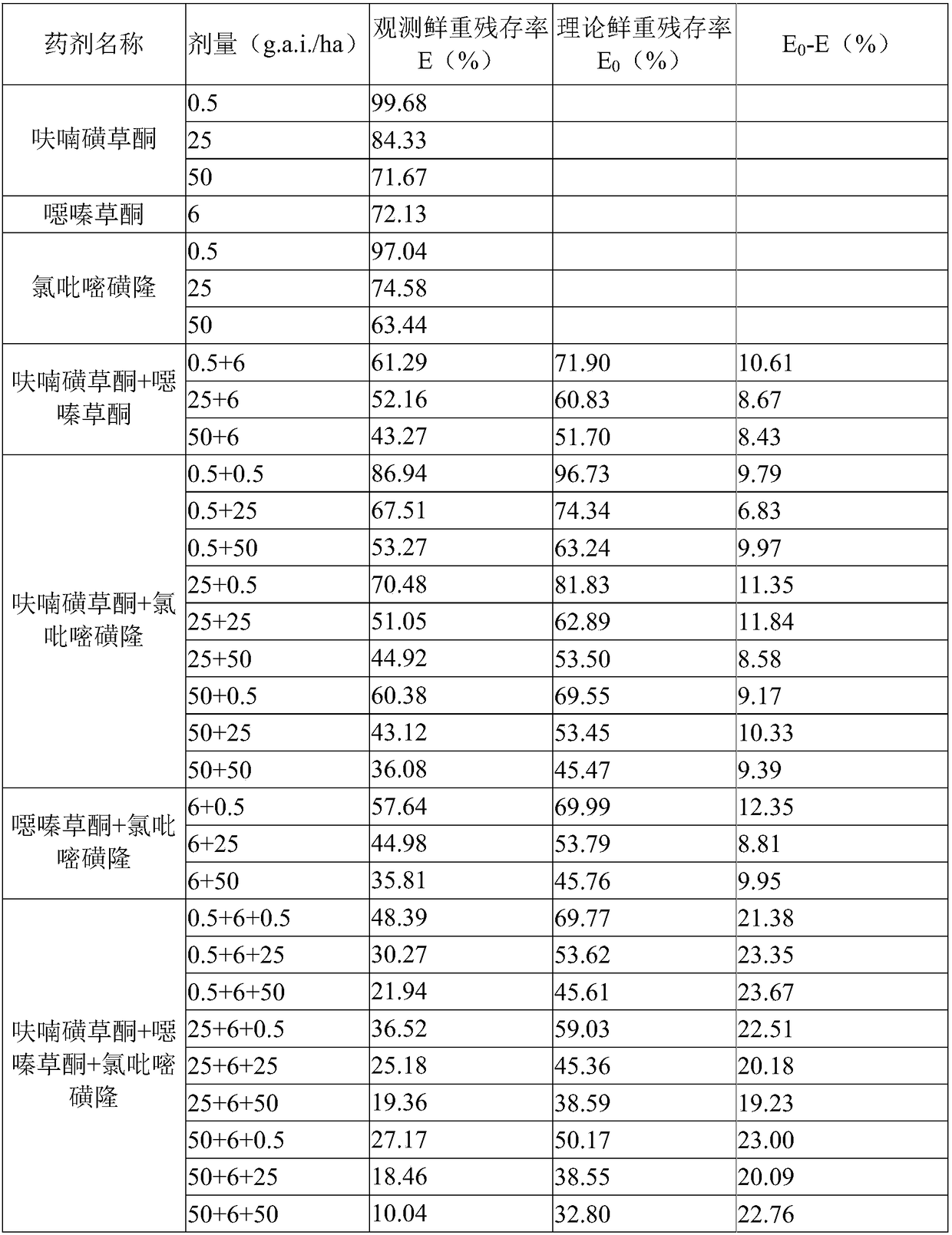

Examples

Embodiment 1

[0037] Example 1: 28% Furosultrione · Oxacitrione · Chlorpyrazosulfuron-methyl Water Suspension Concentrate

[0038]Furosulcotrione 12.5%, Oxacitrione 3%, Clorazosulfuron-methyl 12.5%, Sodium p-Methoxy Fatty Amidobenzenesulfonate 12%, Xanthan Gum 2%, Sodium Benzoate 0.2%, Silicone Oil 0.2% , urea 2%, and deionized water to make up to 100%. The above-mentioned materials are mixed in proportion, uniformly dispersed by high-speed shearing, and sand-milled in a sand mill to prepare 28% furansulcozone·oxaziclodione·chlorpyrazosulfuron-methyl aqueous suspension concentrate.

[0039] A new aqueous suspension formulation embodiment can be formed by replacing clopyrazosulfuron-methyl with one of pyrazosulfuron-methyl, rimsulfuron-methyl, bensulfuron-methyl, promasulfuron-methyl, and pyrazosulfuron-methyl.

Embodiment 2

[0040] Example 2: 31.5% furansulcotrione·oxaziclodione·pyrazosulfuron-methyl dispersible oil suspension concentrate

[0041] Furansulcotrione 25%, oxazicone 6%, pyrazosulfuron-methyl 0.5%, alkylphenol polyoxyethylene ether formaldehyde condensate 10%, calcium dodecylbenzenesulfonate 10%, magnesium aluminum silicate 2 %, canola oil tops up to 100%. The above-mentioned materials are mixed in proportion, uniformly dispersed by high-speed shearing, and sand-milled in a sand mill to prepare 31.5% furasulcotrione·oxaziclodione·pyrazosulfuron-methyl dispersible oil suspension concentrate.

[0042] Replacing pyrazosulfuron-methyl with one of chlorpyrazosulfuron-methyl, rimsulfuron-methyl, bensulfuron-methyl, promasulfuron-methyl, and pyrazosulfuron-methyl can form a new dispersible oil suspension formulation embodiment .

Embodiment 3

[0043] Example 3: 63% furansulcotrione · oxaziclodione · rimsulfuron water dispersible granules

[0044] Furansulcotrione 1%, oxazicone 12%, rimsulfuron-methyl 50%, lignosulfonate 8%, sodium butylnaphthalene sulfonate 6%, crospovidone 5%, diatomaceous earth supplement to 100%. The above-mentioned materials are mixed in proportion, air-jet pulverized and uniformly mixed, kneaded and granulated, dried and sieved to obtain 63% furansulcotrione·oxaziclodione·pyrimsulfuron-methyl water-dispersible granule.

[0045] A new embodiment of the water-dispersible granule formulation can be formed by replacing rimsulfuron-methyl with one of chlorpyrazosulfuron-methyl, pyrazosulfuron-methyl, bensulfuron-methyl, promasulfuron-methyl, and pyrazosulfuron-methyl.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com