Physicochemical-biochemical superimposed enhanced treatment system for printing and dyeing wastewater

A technology for strengthening treatment, printing and dyeing sewage, applied in water/sewage multi-stage treatment, flotation water/sewage treatment, water/sludge/sewage treatment, etc. Equipment impact and other problems, to achieve the effect of shortening sedimentation time, sediment deposition concentration, and reducing hydrodynamic impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

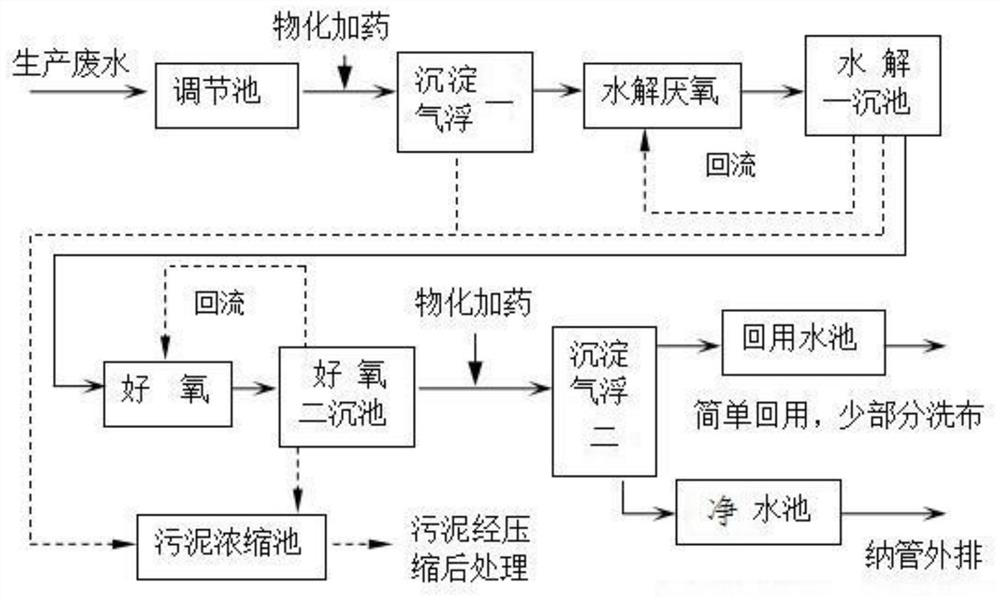

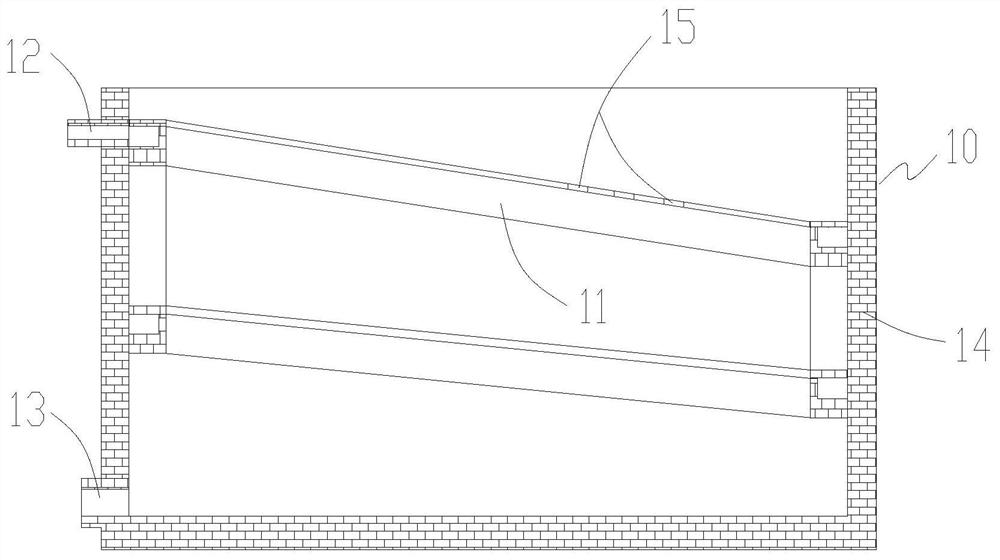

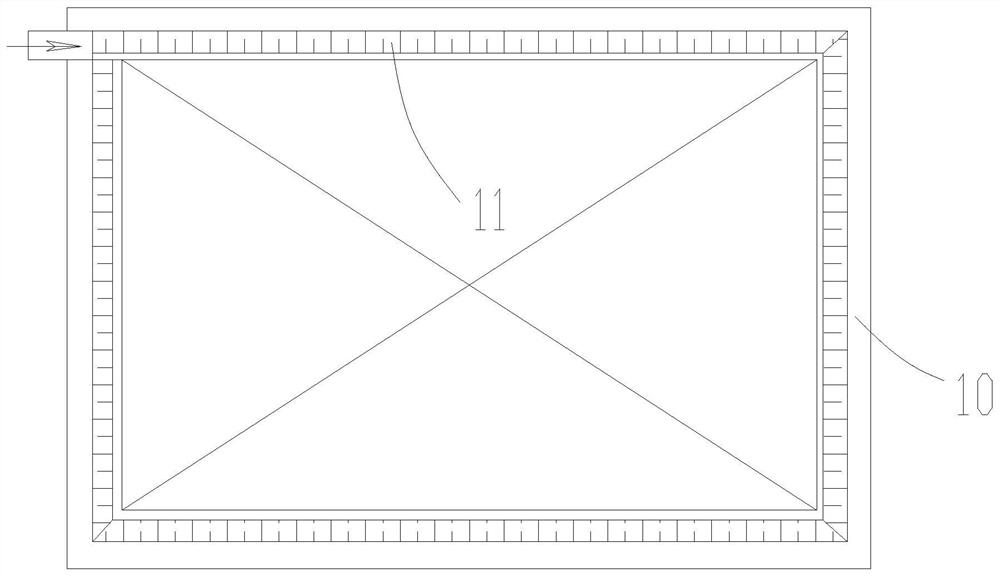

[0029] Such as figure 1 As shown, in this embodiment, a physical-chemical-biochemical superimposed enhanced treatment system for printing and dyeing sewage includes a regulating tank for receiving production wastewater. Then enter the hydrolysis anaerobic process, enter the hydrolysis primary sedimentation tank 20 after the hydrolysis anaerobic, the hydrolysis primary sedimentation tank 20 is connected to the aerobic process, then enter the aerobic secondary sedimentation tank 30, the aerobic secondary sedimentation tank 30 is after the physical and chemical dosing treatment After entering the sedimentation air flotation II, the sedimentation air flotation II is distributed to the reuse water pool and the clean water pool through the waterfall and impact oxygenation. The first settling air flotation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com