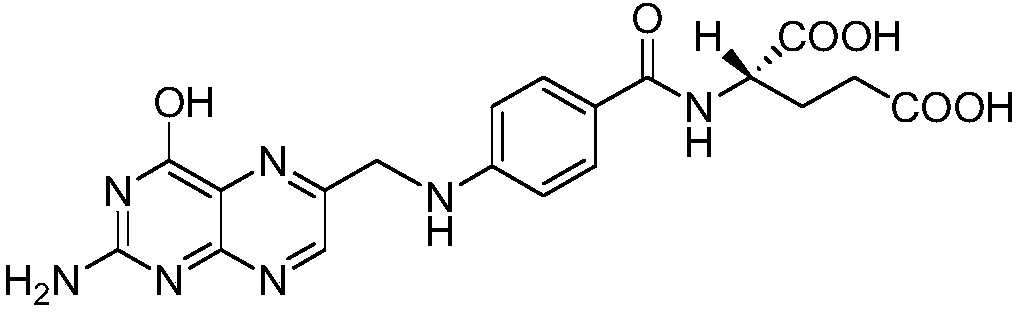

Method for purifying folic acid

A purification method, folic acid technology, applied in the direction of organic chemistry, can solve problems such as inseparable, environmental pollution, difficult waste water, etc., and achieve the effects of low cost, reduced production, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Pump 300kg of methanol into the 500-liter reactor, start stirring, put 43kg of crude folic acid with a purity of 60% from the manhole, start freezing and cool down to 10°C, after stirring evenly, slowly add 86kg of thionyl chloride dropwise from the head tank, At the same time, turn on the air induction and micro vacuum, and keep the temperature of the reactor at 10°C during the dropping process; after the dropping is completed, stir for another 2 hours until the solid is completely dissolved;

[0026] The clarified solution was filtered to remove the insoluble matter, and then the organic solvent was distilled under reduced pressure to remove 90% of the volume of methanol, the solvent was recovered and used mechanically, cooled to 0°C and stirred slowly for 2 hours, and the pure product of folic acid was obtained by pressure filtration after crystallization. The purity of folic acid was 97%. The yield was 96.6%.

Embodiment 2

[0028] Pump 220kg of ethanol into the 500-liter reactor, start stirring, put 43kg of crude folic acid with a purity of 63% from the manhole, start freezing and cool down to 10°C, after stirring evenly, slowly add 129kg of thionyl chloride dropwise from the head tank, At the same time, turn on the air induction and micro vacuum, and keep the temperature of the reactor at 10°C during the dropping process; after the dropping is completed, stir for another 2 hours until the solid is completely dissolved;

[0029] The clarified solution was filtered to remove insoluble matter, and then the organic solvent was distilled under reduced pressure to remove 80% of the volume of ethanol. The solvent was recovered and used mechanically. After cooling to 0°C, it was slowly stirred for 2 hours. After crystallization, it was press-filtered to obtain pure folic acid. The yield was 96.0%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com