CAN bus-based motor bench experiment device and load control method

A CAN bus, bench experiment technology, applied in the direction of motor generator testing, improvement of basic electrical components, etc., can solve the problem that magnetic powder cannot transmit torque, and achieve the effect of simple structure, rich content, and improved flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

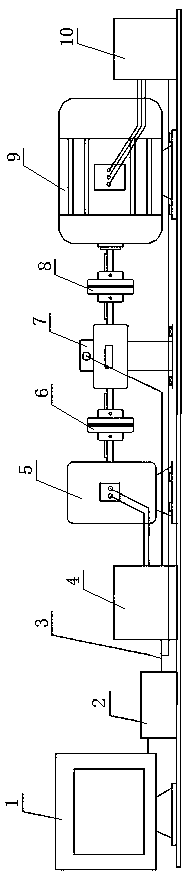

[0026] A CAN bus-based motor bench experiment device, which consists of: a magnetic powder brake 5, the magnetic powder brake has an excitation control terminal interface, the excitation control terminal interface is connected to the excitation controller 4 through a wire, the The excitation controller is connected to the CAN analyzer 2 through the CAN bus 3, the CAN analyzer is connected to the computer 1 through the USB interface, the magnetic powder brake is connected to the torque sensor 7 through the coupling A6, and the torque The sensor is connected to the motor under test 9 through a coupling B8, and the motor under test is connected to the motor controller 10 through wires.

Embodiment 2

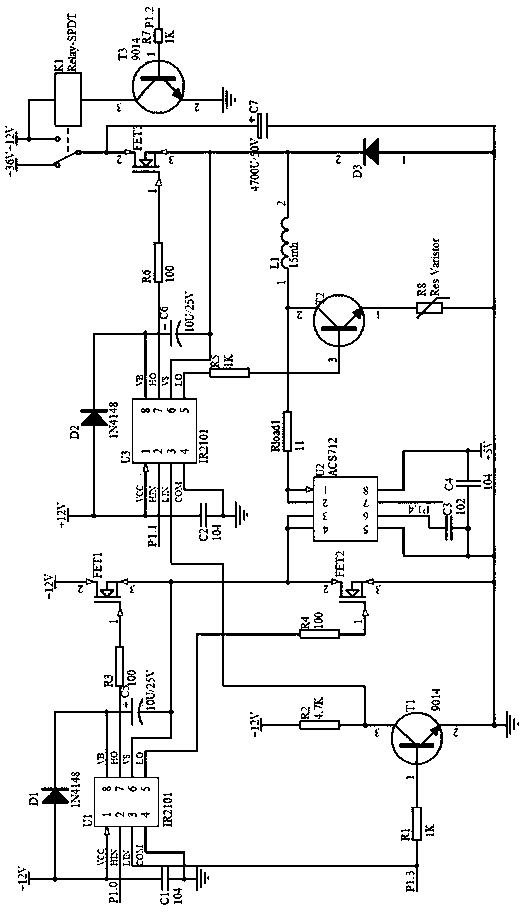

[0028] According to the CAN bus-based motor bench experimental device described in embodiment 1, the excitation controller has a single-chip microcomputer inside, the CAN bus interface of the single-chip microcomputer, the CAN communication interface of the motor controller and the The CAN analyzer is connected, the front end of the torque sensor has a signal output terminal, and the signal output terminal is connected to the excitation controller through a wire.

Embodiment 3

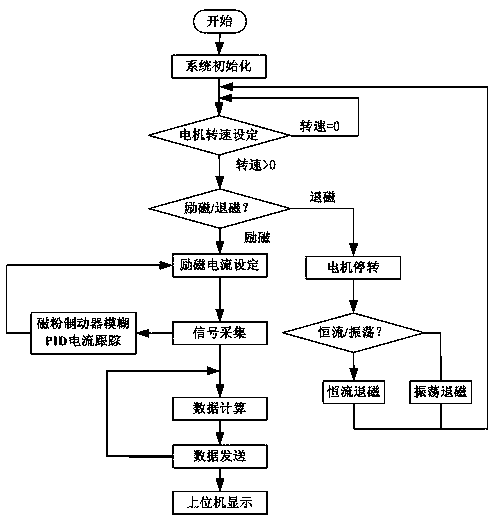

[0030] A load control method using the CAN bus-based motor bench test device described in Example 1-2. This method is: firstly, the computer, CAN analyzer, excitation controller, magnetic powder brake, torque sensor, and The measuring motor is installed on the bench, and the virtual instrument software LabVIEW is used to design the upper computer interface for the platform. The upper computer interface displays the motor speed, torque and excitation current in real time, realizes continuous adjustment of the magnetic powder brake excitation current, and controls the motor speed , Excitation / demagnetization function switch, choice of two demagnetization methods, display demagnetization curve, real-time display of data information transmitted by CAN bus, data can be stored in the form of graphs, tables, etc.;

[0031] The CAN analyzer is connected to the computer through a USB interface to realize bus two-way data transmission, receive computer instructions, upload the collected sys...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com