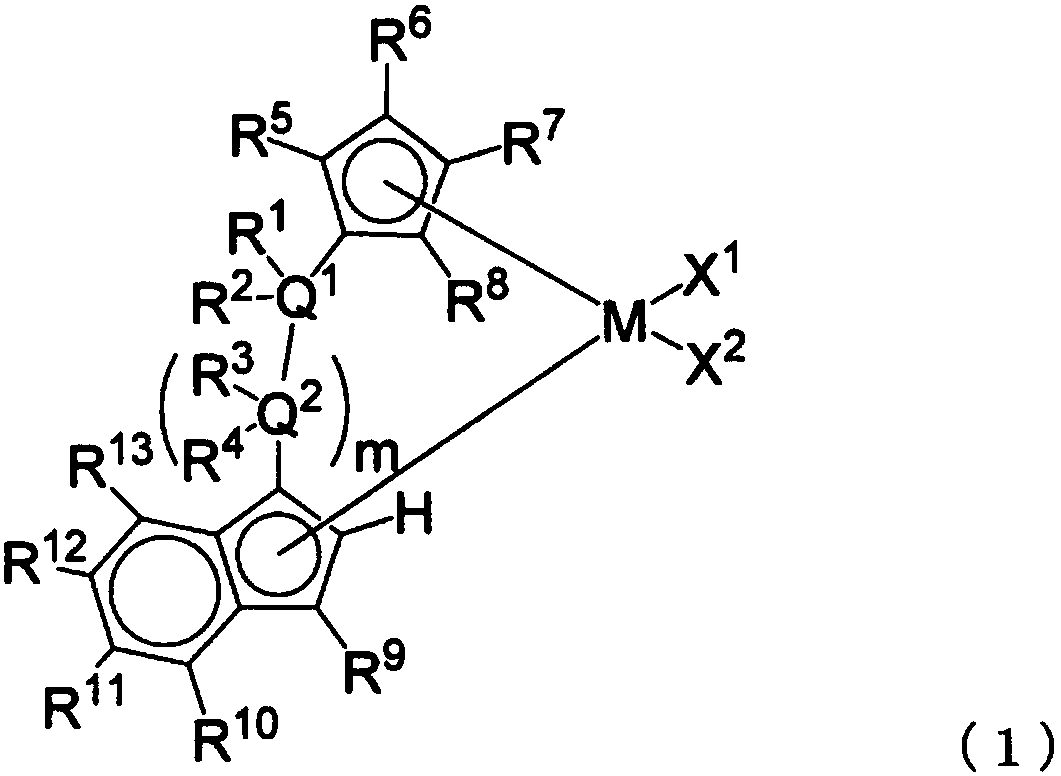

Metallocene compound, olefin polymerization catalyst component and olefin polymerization catalyst each comprising same, and method for producing olefin polymer using said olefin polymerization catalyst

A metallocene compound, transition metal technology, applied in chemical instruments and methods, metallocene, silicon organic compounds, etc., can solve the problems of high production cost and reduced mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0220] 4. Preparation method of catalyst for olefin polymerization

[0221] There is no particular limitation on the method of contacting the components when obtaining a catalyst for olefin polymerization consisting of the component (A) of the metallocene compound which is an essential component of the production method of the olefin-based polymer of the present invention, and Component (A) is reacted to form component (B) of a cationic metallocene compound and component (C) as a fine particle carrier, and for example, the following method may be arbitrarily employed.

[0222] (I) After component (A) and component (B) are brought into contact with each other, component (C) is brought into contact therewith.

[0223] (II) After component (A) and component (C) are brought into contact with each other, component (B) is brought into contact therewith.

[0224] (III) After component (B) and component (C) are brought into contact with each other, component (A) is brought into conta...

Embodiment 1

[0452] (1) Preparation of solid catalyst

[0453] Under a nitrogen atmosphere, 5 g of silica calcined at 600° C. for 5 hours was put into a 200 ml two-necked flask, and dried under reduced pressure by means of a vacuum pump for 1 hour while heating on a 150° C. oil bath. 69 mg of metallocene compound A was put into a separately prepared 100 ml two-necked flask under a nitrogen atmosphere, and the compound was dissolved in 13.4 ml of dehydrated toluene. At room temperature, 8.6 ml of a 20% methylaluminoxane / toluene solution manufactured by Albemarle Corporation was added to the toluene solution of the metallocene compound A, followed by stirring for 30 minutes. While heating and stirring a 200-ml two-necked flask containing vacuum-dried silica placed therein on an oil bath at 40°C, the reaction product of the entire amount of metallocene compound A with methylaluminoxane Toluene solution was added to it. After the whole was stirred at 40° C. for 1 hour, the toluene solvent wa...

Embodiment 2

[0459] In addition to using 11 mg of the solid catalyst obtained in the preparation of the solid catalyst in (1) of Example 1, introducing 85 ml of hydrogen gas under normal pressure before introducing ethylene containing 10% by weight of 1-butene, and changing the polymerization time to Except for 34 minutes, an ethylene-1-butene copolymer was produced in the same manner as in Example 1.

[0460] As a result, 31.4 g of an ethylene-1-butene copolymer was formed. The MFR of the obtained copolymer was 0.62 g / 10 minutes. The polymerization conditions are summarized in Table 14 and the polymerization results are summarized in Table 15.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com